End users involved with a food and beverage operation will know that product safety and compliance are paramount. One of the biggest concerns is bacteria, which can form in the most unexpected places, including often-overlooked locations within a machine’s cabling and connectors. Lapp Group has a long history of helping manufacturers keep these areas as clean and germ-free as possible through innovative products that are designed to resist bacteria and other contaminants.

The Lapp Group has been collaborating with many well-known organisations within all market segments to help them increase the productivity and safety compliance of their food and beverage operations, including:

• Dairy processing.

• Meat and fish processing.

• Baking and confectionery.

• Bottling plants.

• Packaging equipment.

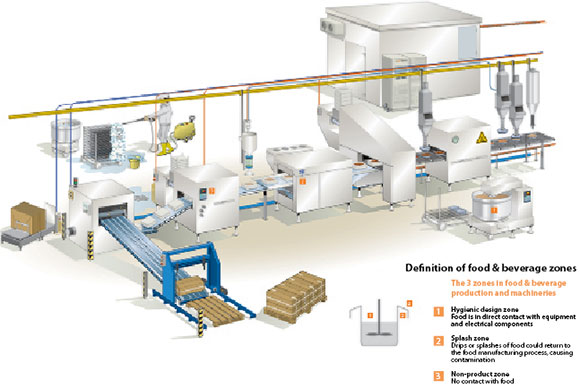

Lapp Group components will be found hard at work powering operations in all these applications and providing optimum hygiene protection in three key manufacturing zones:

1. Food zone: this is where machine parts such as stirrers, filling nozzles, blades, and cutters come in direct contact with food.

2. Splash zone: these are areas and machines that come in contact with food through spraying.

3. Non-food zone: this includes all parts of the plant not in direct contact with food, such as secondary packing machines, as well as equipment located outside washdown areas.

A spotless record in food and beverage production

The Food Safety Modernization Act of 2011 (FSMA) states that food producers must take all the necessary steps to prevent food-borne illnesses and pathogens. This reform is critically important to both manufacturers and consumers:

• One food-borne pathogen can shut down an entire plant, which along with the associated reopening, can result in many hours of downtime that can cost millions of dollars.

• Roughly one in six Americans will contract a food-borne illness every year.

Lapp Group helps manufacturers remain compliant by offering a reliable range of products that are Ecolab certified and use FDA approved materials. They provide maximum uptime and safety for food and beverage manufacturing applications; and with eight integrated brands to choose from, you can rely on Lapp Group to be the only resource you’ll ever need. (Statistics from www.cdc.gov.)

Skintop Inox and Skintop Hygienic

Leading the way are the FSMA-compliant cable glands Skintop Inox and Skintop Hygienic. These are compact, corrosion-resistant stainless steel cable glands with unique design features that prevent microorganisms and bacteria from sticking to surfaces. Their smooth contours and large corner radii, as well as the lack of exposed threads, prevent the accumulation of bacteria and fluids for the safest cleaning possible.

Both of these Skintop products feature specially moulded seals to eliminate any gaps between components where bacteria can collect. Instead of the traditional hexagonal capnut design, rounded edges and flat surfaces allow for the tightening of the gland without the corners and grooves in which microbes could settle. The cable glands are also compliant with industry standards for sanitary fabrication design.

Laboratory and workplace tested

In laboratory tests, Skintop Hygienic and Skintop Inox have been classified as harmless in the production of food and beverages. They also passed a mechanical load test for sealing ability and strain relief. Hygienic is built with FDA-approved materials and both carry Ecolab certification. With Skintop glands, users are assured of consistent, durable and contaminant-free performance.

Silvyn protective cable conduit and connectors

Lapp Group’s Silvyn line is the perfect complement to Skintop at helping to ensure a bacteria-free connection environment. Silvyn food-grade PVC conduits and connectors are made with FDA-approved material and carry Ecolab certification. Designed especially for food and beverage applications, Lapp Group’s Silvyn conduit and connectors help to provide a pathogen-free connection environment.

| Tel: | +27 11 201 3200 |

| Email: | [email protected] |

| www: | www.lappgroup.co.za |

| Articles: | More information and articles about LAPP Southern Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved