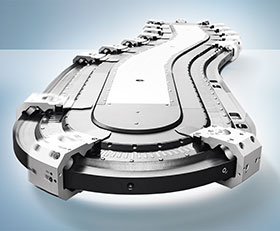

Since its launch at the Hannover Messe in 2012, the eXtended Transport System (XTS) from Beckhoff has already found its way into numerous new machines. In the most diverse forms – from simple to highly complex – it has supported the development of innovative automation concepts. The usage possibilities, especially in large-scale applications, are illustrated by a multi-XTS application, which was shown at SAP’s trade show booth at Hannover Messe 2016, among other venues, as a demonstrator of a smart factory production line.

The 4 × 6 m multi-XTS demo application, which is used in this example for transporting and sorting different beverage cans, consists of five XTS systems with a total track length of 26 m and 100 movers. 72 movers run on the inside of the 17-metre long outer XTS alone. In addition there are also two 4-metre long elevated systems, each with up to 12 movers running on the outside, as well as two lifting stations, each consisting of two vertical 25 cm XTS modules. Each of the lifting modules has one of the new 70 mm movers for increased payload.

Complex motion control enabled by simple software configuration

In this complex system, the high flexibility of the software-based motion control functionality is obvious: each mover, as a self-contained servo axis, can be controlled individually or even synchronised to other movers or process sequences as required. As a property of each mover, the dynamics can be changed individually at any time and on the fly according to requirements. In the example application, this means that a mover can transport a smaller white beverage can faster than the larger red cans and will move even more dynamically than that with no can at all.

Several processing and accumulation stations have been implemented. For example, the cans are transferred to the two elevated XTS systems by a lifting device, comprised of two movers connected by a mechanism consisting of a gear wheel and toothed rack. For the lifting movement, the arriving mover in the lower system and the first of the two coupled movers in the upper system must be synchronised with each other. Subsequently the second upper mover moves relative to the first in order to pick up the can from the lower mover via the gear wheel mechanism. This device allows the cans to be buffered according to the desired sorting procedure and subsequently transferred back to a mover in the lower system.

The synchronisation of two cam plates ensures that no additional lifting movement of the two coupled movers is generated when driving through curves so the can is transported without jerks. The relative distance between the movers will always remain constant, even when driving into and out of the curve. Through control software parameterisation it is possible to switch between the two corresponding cam plates ‘can up’ and ’can down’, allowing the complex lifting function to be implemented in a very simple and extremely flexible way.

Preconfigured function blocks simplify the implementation and TwinCAT software provides ideal support for the simple implementation of any desired movement. The individual movers can be mapped as conventional servo axes with all common motion control functions such as flying saw, electronic gearbox and cam plate. Specific XTS requirements, such as automatic accumulation, collision avoidance, jerk avoidance and centrifugal force limitation, can be realised with functional extensions in TwinCAT.

In addition, complex kinematics involving two or more movers are already integrated within the XTS motion control toolbox, using which, users can define, for example, a group of several movers as a 2- D axis (X/Y table) or a 3-D axis. The software will then control the entire mover group based on the selected kinematics. In addition, an interface is available via which kinematics can be directly implemented with CNC commands (G code). Furthermore, integrated condition monitoring enables online monitoring of the movers during operation. In this way, maintenance work can be planned proactively and machine downtime reduced to a minimum.

The preconfigured function blocks facilitate a station-oriented implementation of the transport and handling tasks. For instance, the cans must be accumulated before entering more time-consuming processing stations such as the lifting stations. This can be achieved through simple configuration, by defining corresponding accumulation zones at the desired system locations in the software. At a higher control level, the individual movers are then merely sent from one station to another, irrespective of whether they are configured as transport, waiting or processing stations. Thus, a waiting station uses the collision avoidance provided by TwinCAT so that all movers automatically accumulate behind the mover in first place. If the first mover drives onwards, the second-placed mover simply takes its place. Synchronous movements, for example, can also be realised with similar ease. In this case, the station to which the mover should travel synchronously with the next passing mover is configured in the corresponding function block.

Multi and many-core technologies tap performance potentials

The multi-XTS application is controlled by a C6930 control cabinet PC equipped with an Intel Core i7 quad-core processor. One of the processor cores is responsible for the Windows operating system, while the other three are reserved for control functions via the TwinCAT Core Isolation function. One of these is responsible for NC axis control, while the other two calculate the respective XTS travel paths. Due to the parallelisation, the available computing power is significantly increased compared with sequential processing by a single-core CPU, so that such a multi-XTS application can be realised with extreme efficiency.

Further improvement can be achieved by the use of the C6670 industrial server, which has up to 36 processor cores. This many-core technology provides significantly higher computing power for the integration of additional functions into the multi-XTS application. A prime example of this is computationally intensive condition monitoring functionality, which allows, for example, the early detection of wear in a mover roller or soiling of the guide rails. For this purpose, the computer platform must acquire a huge amount of data and continuously analyse it to detect certain threshold values or vibration frequencies. The immense computing power of the C6670 is required in order to be able to realise this not just at certain places in the multi-XTS application, but also for the complete track length and for all movers continuously.

The multi-XTS application as an Industrie 4.0 demonstrator

At Hannover Messe 2016, the close integration of manufacturing processes with business processes was presented by SAP, Beckhoff and other technology partners on the multi-XTS demo application. Here, the XTS transported the products to be processed to the individual processing stations and positioned them there – individually and highly dynamically – and the SAP software communicated directly with XTS via standardised services. Acting as a ‘job languages’ interface, the TwinCAT software established a link between the machine and SAP. The job communication was based on the concept of the service-oriented architecture (SOA), which was implemented with OPC UA.

The demonstration showed the manufacture of a key fob with integrated smart chip and personalised faceplate. One of the biggest advantages of product handling by XTS became apparent here because, following the entry of a job, the initial part was transferred to a mover, which then guided it through the processing machine – individually traceable at all times – where it was assembled to form a complete key fob. The paradigm change envisaged by Industrie 4.0 could thus be implemented: the manufacturing process is no longer centred on the machine, but seen from the point of view of the product to be manufactured and can also be programmed accordingly. Ultimately, an individual product can be produced in a lot size of 1 using industrial mass-production methods and managed by a higher-level ERP system.

For more information contact Kenneth McPherson, Beckhoff Automation, +27 (0)11 795 2898, [email protected], www.beckhoff.co.za

| Tel: | +27 11 795 2898 |

| Email: | [email protected] |

| www: | www.beckhoff.com |

| Articles: | More information and articles about Beckhoff Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved