The earlier attempts in the 1980s to introduce electronic control, monitoring and metering, and the technological innovations of the 1990s – digital control systems, graphical interfaces and software – were the seeds of the current Smart Grid. These developments made two-way communication implementation in the electrical grid possible.

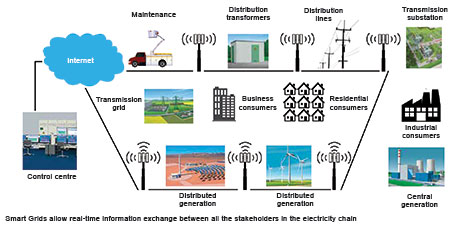

The inclusion of different distributed power generation sources, mainly renewables and storage devices like electrical vehicles (EV) or batteries, created a change in the paradigm of the electrical grid. In the past, there were hundreds of centralised generation sources and one-way distribution networks, but with this shift, thousands of distributed generation sources and bi-directional networks were possible, increasing the complexity of the electricity distribution process.

Real-time communications, bi-directional transformers and sound network topology transformed consumers into prosumers, with the ability to act as a consumer at certain hours of the day and an electricity supplier during other hours. For example, consumers could now store energy at night within batteries and support energy consumption at peak demand times in the morning. This type of network communication already existed in the HV substations and in most of the MV substations; the challenge of the Smart Grid is to bring this communication to the distribution grid and from the LV transformers to house meters.

Advanced communications are essential for enabling modern grid applications, such as grid visualisation, real-time load monitoring, automated demand response, advanced protection, asset monitoring, smart metering and consumer load control. What are the combined communication requirements of the modern grid?

• Bandwidth: Each single device needs a stable bandwidth to allow for services planning; the bandwidth needs to be the same for all the devices.

• Latency: Time delay in the communication needs to be known and tied. Time critical applications in electric utilities are direct in fibre, so latency should not be a big challenge in Smart Grid applications.

• Security: Any communication network needs to provide mechanisms to prevent and monitor unauthorised access, misuse, modification, or denial of access to both data and physical assets.

• Reliability: Dependability, or reliability, describes the ability of a system or component to function under stated conditions for a specified period of time or at a specified moment or interval of time.

Advantages of cellular wireless communications over public networks

Using cellular over public networks combines the benefits of high penetration frequencies with the already available backbone from the telecom utilities connected to the Internet. High speed data access over cellular communications is a new choice for reaching local assets in remote utility facilities and third-party installations.

The cellular technology is used to transfer data in a secure and reliable way and provide connectivity over a public network to utility substations, energy generation locations, utility offices and secondary transformation centres.

This 4G technology is ideal for Smart Grids, as it allows for the two-way communication, remote monitoring and control of the grid, quick and easy installation and broadband speeds. With 4G, utilities can remotely locate, isolate and restore power outages, thereby increasing the stability of the grids. The multiple megabits supported by 4G significantly outpace the bandwidth supported by outdoor WiFi, digital cellular or proprietary solutions, giving grid operators an ability to not only address the primary meter communications requirements of the network, but also to leverage a common platform for real property management, mobile workforce connectivity (including VoIP support) and CCTV camera security backhaul.

There are a number of advantages for using wireless communications networks in Smart Grid deployments, including:

• Access: Gain access to information, anytime, anywhere.

• Mobility: Mobile workforce connected to company intranet or to systems with no cables.

• Interoperability: Countrywide networks via different mobile operators allow redundancy and backup systems.

• Reduced cost and complexity of network deployments: No fixed infrastructure deployment needed, uses existing infrastructure and the air.

• Availability of technologies with different characteristics from which to choose: Short range WiFi or ZigBee, city range via cellular 3G or 4G-WiMax or radio, long range via radio-microwave or operator’s backbone.

With these advantages come a variety of questions to consider, including:

• Which technology do we choose for our specific application? What characteristics do we look for?

• What implications does this wireless technology have for the specific environment?

• Are there any deployment or interference issues?

• Are there scalability issues?

• Would using a public network compromise the security or redundancy of the network?

Choosing the right wireless solution

Network engineers need a complete solution for Smart Grid applications, from the cables, connectors, patch cords and patch panels, to a broad portfolio of wireline and wireless switches, routers and firewalls for harsh environments. What should engineers look for when choosing the right wireless solution?

• Compact Ethernet port LTE router for unlimited network connectivity.

• Integrated firewall for maximum perimeter protection of the network.

• Dual SIMS for network redundancy to ensure connectivity availability in case of network failure.

• GPS for geospatial localisation allows engineers to check the connection status of each device and ensure network security and availability.

A few solutions for effective cellular communications include:

• Compact 2 Ethernet port LTE router.

• Integrated firewall.

• Two SIMS for network redundancy.

• One serial port.

Conclusion

Data networks for Smart Grid applications need to operate reliably in harsh environments and withstand high electromagnetic interferences (EMI), large temperature variations, shocks, vibrations and dust. This requires special performance features and a high degree of resilience.

Smart Grid communications networks are becoming even more sophisticated, and data rates are increasing to support new grid applications, such as distribution automation devices, metering infrastructure, security and mobile devices. Wireless technologies are the ideal solution for ensuring the reliability of these communication networks. The monitoring, analysis and control capabilities that come with wireless solutions and a modernised grid ultimately improve the reliability, economics and overall sustainability of the production and distribution of electricity, and help Smart Grid engineers keep their networks up and running.

For more information contact Jacques Liebenberg, IAC, +27 (0)12 657 3600, [email protected], www.iacontrol.co.za

| Tel: | +27 12 657 3600 |

| Email: | [email protected] |

| www: | www.iacontrol.co.za |

| Articles: | More information and articles about Industrial Automation & Control (IAC) |

© Technews Publishing (Pty) Ltd | All Rights Reserved