The transformation of the industrial sector has begun. Information-driven systems based on increased connectivity, real-time data, advanced analytics, and execution software can deliver better performance and enhance competitive advantage – not only in the plant, but across a global industrial enterprise and out to its value chain. Many suppliers are developing and deploying new Industrial Internet of Things (IIoT) solutions. Thanks to intelligent, connected production assets and new service models, companies are improving performance, reducing operating costs, and increasing reliability.

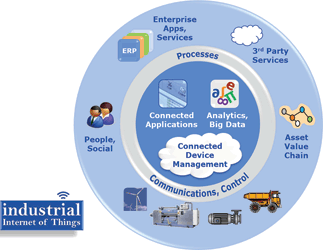

According to Accenture, the IIoT could add more than $10 trillion to the global economy by 2030, opening up new opportunities for economic growth and competitiveness. ARC Advisory Group defines the IIoT as connecting intelligent physical entities, such as sensors, machines, and other assets to each other, to Internet services, and to applications. The IIoT serves up data from connected devices in the plant or in the field and then processes those data using sophisticated new analytics and execution software systems. This sets the stage for operational improvements and for implementing new and innovative business processes. Smart connected products and machines can be more flexible and perform better than their unconnected predecessors.

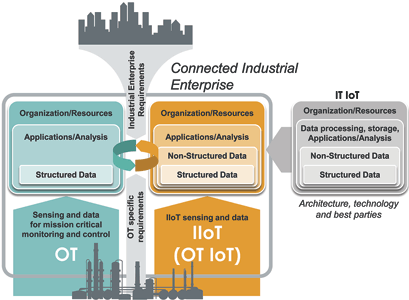

The IIoT architecture builds upon current and emerging technologies. IIoT-enabled solutions, which combine appropriate elements of both operational technology (OT) and information technology (IT), have the potential to bring plant and business performance to a new level. Yokogawa’s industrial automation (IA) product and service offerings, industry domain knowledge, and VigilantPlant approach – which emphasises safe, secure, and uninterrupted operations – provide a solid foundation for the Industrial Internet of Things that specifically addresses the requirements of process automation, particularly for the OT side of the equation. To be able to provide an equally solid foundation for the IT side, Yokogawa is partnering with Cisco Systems and other industry leaders.

Collaborative engineering

Yokogawa is focused on the potential project, operations and maintenance benefits that IIoT can deliver for their customers across a broad cross section of industries. To reduce engineering times during the design phase of automation projects and reduce travel time and costs for engineers and designers, The company is developing effective and secure methods for performing simultaneous, remote collaborate engineering via the Internet. This includes the ability for engineers and designers based in different competency centres around the world to 'meet' in cyberspace and share data, information, and design documents via web-enabled applications. This represents the true application of concurrent engineering practices to automation projects, where multiple engineers and project personnel can have access to up-to- date project information regardless of where they reside. In the example provided, DCS engineers located in Yokogawa’s Industrial Automation (IA) Center in Tokyo could collaborate effectively with EPC engineers in the US, engineers from a packaged equipment supplier based in Europe, and engineers and other end users from the owner-operator based in the Middle East.

Big Data analysis provides intelligence for both routine and non-routine operations

Today’s industrial facilities generate tremendous amounts of data from connected devices, machines, plant equipment, systems, and software applications. As more ‘things’ become smart and connected, the volume and variety of data that must be collected, managed, stored, and parsed will only increase, creating new challenges at both the OT and IT levels. To gain value from this Big Data and improve the total cost of ownership (TCO) for industrial assets, owner-operators will have to take full advantage of the advanced analytics solutions now coming onto the market for industrial applications.

Yokogawa believes that by analysing the OT-related Big Data generated by IIoT-connected plant assets and providing the resulting analysis to the right people, applications, and systems in an appropriate timeframe and context, industrial organisations can optimise their operations to both improve TCO and achieve operational excellence (OpX). The organisation’s efforts here focus on two areas:

1. Providing feedback for humans to interpret and act upon for non-routine OT-related work processes.

2. Develop real-time logic and intelligent applications to trigger the appropriate automated responses in mission-critical systems for routine processes. This builds upon Yokogawa’s leadership in modular procedural automation (MPA). Big Data analytics offer exciting potential to bring MPA to the next level.

Conclusion

Yokogawa’s vision for the IIoT is to add significant value in the OT domain, while helping ensure the prerequisite integration of OT by working closely with both IT suppliers and end users. In addition to supplying a wide variety of related industrial hardware, software, and services, this includes taking advantage of the company’s deep knowledge of industrial organisational issues; real-time data processing, data storage, and analysis; and managing data from devices, machines, and other ‘things’ in the plant and in the field.

Images published courtesy the ARC Advisory Group.

For more information contact Christie Cronje, Yokogawa South Africa, +27 (0)11 831 6300, [email protected], www.yokogawa.com/za

| Tel: | +27 11 831 6300 |

| Email: | [email protected] |

| www: | www.yokogawa.com/za |

| Articles: | More information and articles about Yokogawa South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved