Global warming, acid rain, air, water and soil contamination are all environmental issues that must be managed. Governmental and environmental pressure to monitor and reduce pollutants introduced into the environment will continue to increase. ABB’s emissions monitoring solutions have helped a wide variety of industries for over 50 years through continuous emission monitoring systems (CEMS) designed to help customers maximise profit while operating in a sustainable way through technology and expertise. ABB CEM solutions provide compliance with international, national and local environmental directives for measuring and reporting.

ABB CEM analysers and systems are offered using various combinations of technologies, such as; Fourier Transform Infrared Spectroscopy (FTIR); IR; UV; TC; Zirconium/paramagnetic/electrochemical oxygen and FID for VOCs.

All ABB extractive CEM stand-alone analysers and integrated systems can optionally be supplied with complete application based ABB sample handling systems that close the loop to ensure compatibility with environmental legislation.

* ACF series is a fully certified analyser system which accurately monitors the hot/wet composition of exhaust gases. It is a completely pre-engineered FTIR CEM System made for easy operation. It has the lowest maintenance interval in the market. QAL3 automatic span drift check without test gas optionally available.

* ACX series is a fully certified analyser system which accurately monitors the dry base composition of exhaust gases. It is a completely pre-engineered modular analyser system made for easy operation. QAL3 automatic span drift check without test gas optionally available (cost effective option when hot wet values are not required to be measured).

* Advance Optima/Easyline ranges are fully certified analysers that accurately monitor the dry base composition of exhaust gases. Individual analysers measuring up to six application based component values can be engineered according to plant/customer requirements. QAL3 automatic span drift check without test gas optionally available (can be a cost effective alternative to ACX).

ACF series

ACF series with more than 1500 installations worldwide make this the most referenced and reliable solution, positioning ABB globally in terms of emission control. ACF is therefore an environmental monitoring system of the highest quality. It can rightly be called state-of-the-art as it has demonstrated in the field its safety features, stability, compliance with industry legislative standards and ability to detect gases at low concentration.

ACF is suitable for all components, including water soluble – typically NO, NO2, N2O, NH3, SO2, HCI, CO, CO2, CH4, H2O, HF, O2 and VOC via FID / FTIR.

ACF offers Measurement of up to 15 gas components making use of the hot/wet extractive method of measurement. Powerful FTIR technology is used in conjunction with proven FID and ZrO2 sensors to measure all components including the unburned hydrocarbons and the oxygen content from a single sample from one sample point. It is a pre-engineered system with a compact and modular design.

Communication, control and maintenance via fieldbus and Ethernet/TCP or modem are all available separately or combined if multiple methods are required.

ACF benefits

Reliability

* More than 20 years’ experience with FTIR spectrometers in gas analysis and more than 1500 installations worldwide.

* Fully compliant to European and other international environmental legislations.

* Worldwide support through certified service engineers.

Profitability

* 99% System availability.

* Best maintenance interval in the market.

* Maintenance-free sample transportation through an aspirator pump.

* Cost reduction for routine maintenance through remote control and diagnosis.

Flexibility

* Ready for operation – only electrical power supply and instrument air are needed.

* Easy addition of further measuring components – no additional hardware required (except when VOCs are added, hardware will be required).

* Extra gas port to connect other analysers – no need for a separate probe.

* QAL3 automatic span drift check without test gas optionally available (5000).

ACX series

ACX series is a complete cold extractive CEM solution. It is a pre-engineered system solution for continuous gas analysis, including everything from probe, sample lines and sample conditioning to reliable and certified analysers of the Advance Optima series. The system can be operated from a keypad and display in the front door without opening the shelter. The system is available with various options to be tailored to your measuring tasks; it is especially designed for easy service and maintenance.

ACX is suitable for all components, up to six measurable values– typically NO, NO2, N2O, NH3, SO2, CO, CO2, CH4, and O2. (NOx can also be reported as a single component and Dry Base values can be reported at preset normalised O2 value).

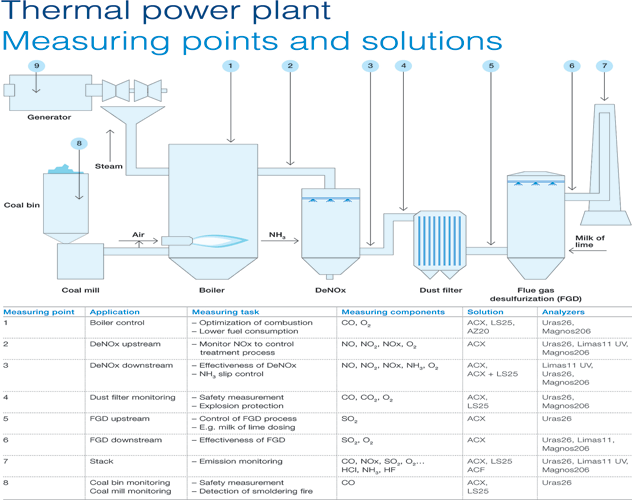

ACX integrated systems can be used for power generation boiler stack CEM and many other measuring points on power plants.

ACX benefits

Reliability

* Compliant according to European, US and international Standards.

* Wide range of proven analysers combined with worldwide support for engineering and certified service.

Profitability

* Saving time and money with automatic calibration through built-in calibration cell without gas bottles.

* Cost reduction for routine maintenance through self-diagnostic and remote control.

Flexibility

* Wide range of options to serve all relevant gas analysis applications.

* Easy integration in customer network through a broad variety of process interfaces and connectivity options.

Advance Optima

The modular gas analysers Advance Optima combine advanced technologies with more than 75 years of experience in process and environmental gas analysis. They are the innovative solution for the demands of today and the challenges of tomorrow. The Advance Optima series can be used in almost every form of production and has proven itself in the toughest processing environments. (Combinations of URAS; LIMAS; MAGNOS; CALDOS; MultiFID; ZO23; LS25)

Advance Optima key features:

* Full compliance with international environmental directives.

* Automatic calibration and proven calibration cuvettes to save time and money for maintenance.

* Top performance with unrivalled economy.

* Up to four fully combinable analyser modules.

* Up to six measuring components.

* Ex versions available.

* In-built PLC functionality with function block programming.

* Multi-analyser systems.

* Simple, user-friendly operation.

* Unlimited communication – information anywhere.

* Analog I/O, digital I/O.

* Remote control available.

* Analyze IT Explorer: comprehensive asset management software including QAL3 functionality.

Advance Optima can be used in many power generation strategic measuring points, including CEM.

EasyLine

EasyLine is both a powerful and affordable series of instruments for the monitoring of gas concentrations in numerous applications. EasyLine is based on the proven and reliable analyser technology that includes LIMAS; URAS; MAGNOS; CALDOS and makes use of ABB for extractive continuous gas analysis principles.

EasyLine key features:

* Full compliance with international environmental directives.

* Internal quality control and fully automatic QAL3 reporting.

* Automatic calibration and proven calibration cuvettes to save time and money for maintenance.

* The efficient alternative.

* Combine two analysers in one enclosure for an excellent price-performance ratio.

* Up to five measuring components in one unit.

* Ex versions available.

* Easy connection for data acquisition.

* Analog outputs, digital I/O, Modbus, Profibus.

* Easy to operate, Asian languages available.

* Internal quality control and reporting.

Easyline can be used in many power generation strategic measuring points, including CEM.

For more information contact ABB South Africa, +27 (0)10 202 6459, [email protected], www.abb.com/za

| Tel: | +27 10 202 5000 |

| Email: | [email protected] |

| www: | www.abb.com/za |

| Articles: | More information and articles about ABB South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved