Industrial PC (IPC) platforms are becoming increasingly popular in remote process control automation. However, traditional PC platforms are not engineered to the standards required by industrial networks, consequently, when building IPC platforms for industrial control, the first hurdle engineers encounter is how to ensure the high reliability and data security demanded by industrial systems. This is a challenge because IPCs were originally designed and engineered for use in enterprise networks, where the consequences of system failure are much less severe. Thus, reducing or eliminating the system downtime that is so common in enterprise networks is the first concern for automation engineers who are considering IPCs for their network.

The benefits and problems of IPC-based automation

Over the past few decades PCs were only suitable for use in scada systems, where the mild conditions of comfortable, climate-controlled offices could be guaranteed. But as Ethernet technology has advanced, the opportunity to build distributed control networks using relatively inexpensive IPCs has become a valuable alternative. The result is that today, IPCs are displacing PLCs and RTUs from industrial control systems. One of the advantages IPCs bring is a significant increase in processing power. Increased efficiency in a production system typically means more and more information must be acquired and analysed, and that translates into a significant increase in data rates. The only way to achieve high-speed, front-end data collection and analysis is with a faster CPU. Thus, one key value point that distinguishes IPCs is the increased processing performance they offer relative to RTUs and PLCs.

These increases in efficiency come with a price though, while IPCs’ processing power makes them a useful application for device control, it also significantly increases the complexity of the platform so that slowdowns and failures become more likely. Yet, in remote automation systems – and especially in oil and gas processing control – any failure incurs heavy costs, and if IPCs are installed in remote systems at the device layer then they are naturally beyond the timely reach of system maintainers. For these reasons, whenever IPCs are considered, downtime prevention is the foremost topic in mind.

In enterprise systems, recovery of lost data or crashed devices may be accomplished using redundant drive arrays (RAID), backup system images, or some other rescue and backup mechanism. Following a crash, however, most of these methods require operator intervention to start a recovery, and additionally, none of these approaches prevent cumulative slowdowns or system failures. In contrast, most of the devices that comprise automated oil and gas control systems are located remotely and require much stricter fail-safes than enterprise devices can provide.

Process control for oil and gas systems is so widely distributed that all networked devices must meet strict stability and reliability requirements even without operator presence. One powerful tool that can help guarantee this is an automated OS backup and recovery system. Unfortunately, these tools are mainly useful only after failure has already occurred; ideally, all failures should be prevented with such timely maintenance and oversight that process controls would never crash. But how can this be achieved?

Remote management and self-diagnosis using PC-based controllers

The solution to this problem requires only a few relatively simple steps that result in increased system reliability and overall uptime.

Automate regular system cleanups with full OS rewrites

Everyone who has ever spent a lot of time using computers has experienced how performance cumulatively drops and the system slows down over time. In an automation system, slowed performance means reduced yield, so, to maintain system efficiency, an IPC should be able to restore itself to a pristine state according to a preset schedule.

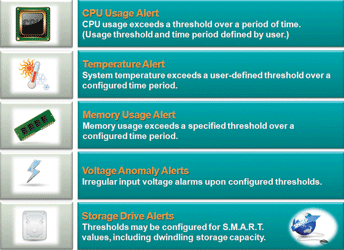

Hardware failures increase in hazardous environments so critical components need to be monitored

Rough environments are commonplace for remote oil and gas control systems. Very high and very low temperatures, high humidity, corrosive sedimentation and electrical interference all expedite the ageing process. To make sure the system administrator can address system instability before the system crashes, hardware health indicators must be monitored and made available remotely for use in predictive maintenance.

Use IP communication for remote triggering of the IPC’s self-healing process

In the past, when IP technology was alien to industrial control networks, most automation systems relied on hardware and software watchdogs to do hard resets to restore the system. There was little a system administrator could see remotely, or do. Normally, to diagnose and fix a problem an engineer had to be physically present at the site; of course, sending an engineer to an offshore platform or remote pumping station incurs high expense and repair times are usually measured in days. Today, however, IP communication allows engineers to monitor an IPC’s health and remotely trigger OS re-writes to a tagged disk image created when the IPC was configured to run efficiently.

None of these methods are new to the computer world, but when put together into a ready-to- run software application this trio of automated monitoring and recovery features constitute a powerful weapon in the fight to ensure a control network’s reliability. To integrate these features, a solution is required that will run not only as an application, but also as a background system process. One protocol that is already widely used to achieve this in remote automation networks is the simple network management protocol, or SNMP.

SNMP as a remote IPC management interface

SNMP was originally created for IT personnel to monitor process efficiency and hardware status on network nodes like routers, switches and power sources. Yet in the last decade it has also aroused the interest of traditional automation engineers, for a variety of reasons.

* First, the protocol is open and free and readily available to everyone. SNMP is an effective and inexpensive tool.

* SNMP carries a light memory footprint while supporting active reporting, making it ideal for remote data acquisition where network bandwidth is a concern. The innovations that came with SNMP v2 allow agents to return active reports to the network management software (NMS) upon operator-configured exceptions. These active reports are called SNMP traps and they give powerful alarming capability.

* SNMP v3 supports data encryption, a critical feature for data that must travel across public WANs. Because they were created for LAN applications, encryption is not available on most Fieldbus implementations.

* SNMP is a protocol that has grown in step with IP technology, being honed with every generation. The prospects for it are bright.

* Finally, there is a wide variety of readily available SNMP-compatible NMS. Many of these implementations are cheap while others are even free, giving industrial control engineers an economical and effective means of monitoring field equipment.

Expanding SNMP into a remote IPC management tool

With IPCs so widely used in so many different automation roles, industrial control engineers need a remote management system that combines both monitoring and control. A fully automated system can be made intelligent by empowering remote IPCs with self-diagnostic routines that utilise SNMP to access diagnostic data, receive alarms and trigger recovery tools whenever system resets are required. All of these indicators are readily available using standard SNMP polling.

| Tel: | +27 11 781 0777 |

| Email: | [email protected] |

| www: | www.rjconnect.co.za |

| Articles: | More information and articles about RJ Connect |

© Technews Publishing (Pty) Ltd | All Rights Reserved