World’s first 4-tube high accuracy Coriolis flowmeter

With its 350 mm diameter and accuracy up to 0,05%, the Promass 83X/84X four-tube Coriolis mass flowmeter is ideal for pipeline custody transfer and other high flow-rate applications requiring reliability and low maintenance. This large diameter unit is ideal for measuring the mass flow, density and temperature of oil, gas and other fluids in large pipes at rates up to 4100 metric tons/hr with extreme accuracy and precision.

“When measuring flow rates up to 4100 metric tons per hour or 720 000 barrels per day of a valuable commodity like crude oil in a large diameter pipeline, accuracy is extremely important,” says Michael Nuber, head of product management Coriolis flowmeters, Endress+Hauser. “An error of 1% in the flow rate represents 300 barrels of crude oil per hour, or about $30 000 per hour at a price of $100 per barrel. It has always been difficult to measure flow with accuracy in large pipelines. Now, the Promass X with its 0,05% accuracy, provides an ideal flowmeter solution for custody transfer on big oil and gas lines, ensuring that both buyer and seller know exactly how much is changing hands.”

The 83X model is supplied standard with fully traceable 0,1% flow accuracy, and optionally with a flow accuracy of 0,05%. The 84X is suitable for custody transfer applications, featuring MID (OIML R117) and PTB approvals. For both models, accuracy of the density measurement is 0,01 g/cm³ (0,001 g/cm³ optional), while accuracy of the temperature measurement is 0,5°C. Both also have a balanced measuring system with high immunity to external pipe vibrations and process influences, and both work in applications with entrained air.

Previously, companies had to use less-accurate conventional flowmeters on larger pipe sizes. Now that the Proline Promass 83X/84X is available in a 350 mm size, it can be used for custody transfer, fiscal metering and other high accuracy applications of gases and fluids. These include pipelines and transfers to and from tanker ships, trucks and rail tankers.

This four-tube flowmeter is made of 316L stainless steel with secondary containment for increased process safety, making it ideal for applications involving toxic or hazardous liquids or gases. The flowmeter has no moving parts, so maintenance is minimised. It operates in process temperatures of -50 to 180°C and in process pressures up to 100 bar. Communication options include 4-20 mA, HART, Profibus DP/PA, Foundation Fieldbus or Modbus.

The units have NEMA 4X/IP 67 rating and ATEX, FM, CSA and IECEx approvals. The Promass 83X/84X fulfils EMC requirements according to IEC/EN 61326 and NAMUR NE21. It also conforms to the requirements of the EU and ACMA directives and thus carries the CE mark.

World’s first dedicated biogas flowmeter

The biogas market has been booming for years. The gas obtained from the fermentation of crops, organic waste, liquid manure, sewage sludge or left-over plant materials can be used in a variety of beneficial ways, including fuelling vehicles or generating heat and electricity in combined heat and power plants. Various process parameters must be monitored around the clock for stable operation of a biogas plant: fermentation temperature, gas pressure and, primarily, the gas quantity produced.

The precise determination of the biogas quantity is a decisive criterion for evaluating the efficiency of a production plant and an indicator of an assured fermentation process. However, to date there have not been any flowmeter systems available on the market that were reliably capable of measuring the quantity of biogas. Now this gap is being filled by the Prosonic Flow B 200 ultrasonic flowmeter, developed especially for such applications. For the first time, this device makes it possible not only to measure the volume of biogas, landfill gas and fermentation gas precisely, but also the methane content directly in the pipe.

Unbeatable ultrasonic flow measurement

The ultrasonic flow measurement offers operators of a biogas plant many advantages compared to traditional measurement methods. Thanks to modern and innovative sensor technology, wet and dirty gases can be measured with high accuracy even under greatly fluctuating process conditions using the Prosonic Flow B 200. The measurement is independent of the gas composition and even possible at very low gas pressures – a benefit unmatched by other flowmeters thus far.

The Prosonic Flow B 200 is an industry-optimised flowmeter with high measuring accuracy (1,5%) and a wide operating range (30:1). It causes no pressure loss and requires no maintenance once installed. The Prosonic Flow B is available in diameters between DN 50 and DN 200 and can be used at gas temperatures of up to +80°C and gas pressures up to 10 bar. As an intrinsically safe two-wire measuring device (Ex ia), the Prosonic Flow B 200 is especially suited for use in hazardous areas. Menu-guided local operation allows the user to configure measuring points according to optimal operating requirements.

Methane content measurement directly in a pipe

Fermentation processes are not always uniform. The operating conditions fluctuate causing different methane content amounts (CH4) in the biogas which must be monitored constantly. In addition to measuring volume flow, it is now also possible to measure the methane content of a gas at the same time, thanks to the ultra-precise sound velocity measurement and integrated temperature sensor in the Prosonic Flow B 200.

Worldwide, this is a one-of-a-kind feature and opens up completely new perspectives for process monitoring. Since gas quantity as well as gas quality can be checked around the clock, a targeted reaction to disruptions in the fermentation process is possible in real-time. As a multi-variable flowmeter, Prosonic Flow B 200 can also calculate additional characteristic values upon request such as the corrected volume, the heating output or the Wobbe index as a performance indicator for fuel gas quality.

Prolonged battery life-time from the SMART Battery Mag

Whether in the tropics or in the desert, the battery-powered Promag 800 gives long-term reliable flow measurement performance, even in the most desolate locations.

Accurate measurement and billing of drinking or spring water is becoming increasingly important. However, optimising drinking water treatment and the distribution network often requires measurements at locations without a power supply. The Promag 800 with battery power supply stands for precisely these applications. This new flowmeter allows versatile and autonomous use even in remote areas for reliable monitoring of water systems, leak detection and accurate cost allocation in custody transfer.

Economical with uncompromising reliability

Outstanding measurement performance, local logging, and secure worldwide remote data transmission via GSM/GPRS, are device properties that stand for stable and verifiable measurement results. In addition, automatic and intelligent adaptation of the measurement interval at fluctuating flow rates enables seamless flow monitoring with maximum battery life.

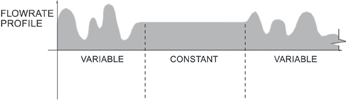

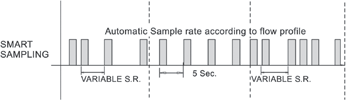

The Battery Mag uses a SMART sampling method for flow measurement. Instead of using a constant sampling rate, the battery mag varies this. The default sampling rate is set at every 5 seconds for every one measuring point if constant. If the flow profile changes, then the sampling rates increases to 0,1 second. By using this varied sampling method, battery lifetime is maximised.

The Promag 800 provides long-term reliability underground or underwater without cost-intensive protective measures. Drinking water and custody transfer approvals (MI-001, OIML R49) are also available for the battery-powered sensor for line sizes up to DN 600.

Ingeniously simple and proven in practice, Endress+Hauser’s flowmeter solutions are designed to strengthen any hand.

For more information contact Frans van den Berg, Endress+Hauser, +27 (0)11 262 8000, [email protected], www.za.endress.com

| Tel: | +27 11 262 8000 |

| Email: | [email protected] |

| www: | www.endress.com |

| Articles: | More information and articles about Endress+Hauser South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved