In today’s challenging economic climate, the ability to capture real-time and historical operational data, and analyse and visualise that data in the right context, plays an increasingly important role in a company’s success. With its ability to provide manufacturers with a plant’s complete digital history, Vijeo Historian V4.30 – the information management layer of Schneider Electric South Africa’s PlantStruxure – offers a powerful plant historian that supports the monitoring and optimisation of critical key performance indicators.

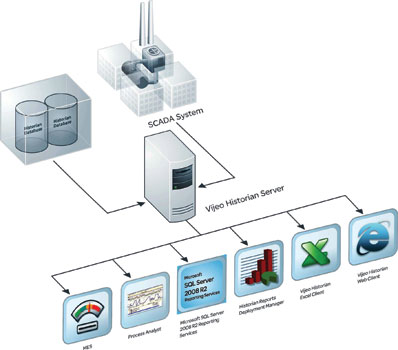

Data analysis within the PlantStruxure architecture

Cost reduction, meeting regulatory requirements and maintaining and improving energy efficiency are three areas in which industry is coming under increasing pressure. Quintin McCutcheon, Scada, MES and Telemetry commercial manager at Schneider Electric South Africa, points out that under these circumstances, industry is becoming increasingly dependent on plant historian technology and collecting process data is no longer a nice-to-have, but a necessity.

“Manufacturing and processing facilities that have invested in plant historian technology, are capturing large volumes of process information which becomes the main source of manufacturing intelligence data,” says McCutcheon. “The simple to complex analysis of this information helps companies to make critical decisions on process performance management.”

Schneider Electric South Africa is offering a robust, easy to use plant historian called Vijeo Historian V4.30, which enables industrial operations to view and analyse large volumes of plant data in real-time. Vijeo Historian constitutes the information management component of Schneider Electric’s PlantStruxure, a collaborative system for process control and energy management.

McCutcheon says PlantStruxure integrates hardware and software components throughout the plant to deliver a complete process management solution. “This measured process and energy data can be analysed and the information used to holistically optimise the plant. New Microsoft platforms are increasingly being adopted by hardware vendors and businesses and these enhance performance of plant historian software.”

Vijeo HistorianV4.30 supports Windows XP, Windows Vista, Windows 7, Microsoft Windows Server 2003 R2, Microsoft Windows Server 2008 R2, SQL Server 2005 and the enterprise edition of SQL Server 2008 R2. The software is compatible with 32-bit and 64-bit operating systems and the enterprise edition also caters for data compression at about 43 percent on process data, which reduces the size of the database.

“The software offers insight into overall operational performance and improves business flexibility via integration with the latest technology platforms such as Windows 7,” says McCutcheon. “It turns masses of data into meaningful information, giving plant management a complete picture of plant processes which enables improved return on assets and improved profit margin.”

New features and improved diagnostics

The new version of the software provides enhanced reports using new chart controls available in SQL server 2008 R2 and offers Dundas-based charts, including advanced chart visualisations and other chart types.

Plant-floor data can be presented in highly visual charts and customisable dashboards. McCutcheon says this ensures that each level of the organisation, from plant operators, production managers, engineers and quality assurers to upper management, have access to the information they need to make better decisions more quickly.

A historian web client feature offers a simple means of analysing alarms, events and trend data, providing a flexible means of comparing realtime and historical data in a single interface. The performance of the configuration manager feature has also been improved so that multiple reads are no longer required every time data is accessed.

From an energy management perspective, McCutcheon says plant historian software plays a key role in energy management. Capturing energy-related data allows users to better understand energy usage over time and determine if energy management procedures are being followed.

“Vijeo Historian is used to identify inefficient plant equipment and processes, diagnose anomalies in power consumption and make realtime adjustments to optimise energy efficiency and save power costs at equipment level, on production lines, across the entire plant and even on multiple sites.”

For more information contact Quintin McCutcheon, Schneider Electric SA, +27 (0)11 254 6400, [email protected], www.schneider-electric.co.za

| Tel: | +27 11 254 6400 |

| Email: | [email protected] |

| www: | www.se.com/za/en/ |

| Articles: | More information and articles about Schneider Electric South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved