Less space requirement, less material, a shorter installation time – today, these are the decisive criteria for developing process plant. Products that fulfil these conditions are favoured by design and plant engineers. One of the reasons for this is the modern general framework used in plant design.

Plants are no longer developed in existing buildings and gradually adapted to how rooms are arranged. They are much more frequently created with a modular design by plant engineers and are only then assembled in the factory. A consequence of this modular build procedure is that a process plant is split into separate functional units such as those for heating, cooling, filtration, cleaning or sterilisation. These units are then pre-assembled separately in what are known as ‘skids’, with all mechanical and electrical components on one frame. The dimensions are generally selected so that the skids can be transported trouble-free and fit through the building entrances at the customer site. They are then connected together using pipes and cables on site according to an existing 3D plan.

An extra advantage of this design is that a plant can be quickly dismantled into its individual parts and reassembled at a different location. In addition, the plant designers already have the option before delivery to test the plant intensively for the customer. However, what is decisive here is that the plant design – depending on the configuration of the plant – can be standardised and also optimised. When constructed on location, all of the parameters have already been pre-installed so that the plant can be put into operation within a short period of time.

Twice as much space as previously

Due to the limited size of the skids, it is particularly important to make best and efficient use of the space available. Compact components are therefore beneficial. With very shallow space underneath or when fitting in proximity to walls and floors, the available space is very limited. What is required here is intelligent, constructive solutions that allow for as little expenditure and materials as possible.

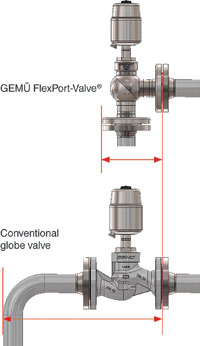

The new FlexPort Valve product line from Gemü opens up a range of new possibilities to plant engineers and design engineers. The product range reduces the installation length by up to 50%, a small revolution in the field of process plant construction. A 50% reduction in the installation length means twice as much free space as before. The spherical design of the FlexPort stainless steel globe valves is suitable for installation in narrow and restricted spaces.

High flow rate guaranteed

The angle valve version is particularly attractive here for plant designers. The version with an angle of 90° only requires half as much space as a conventional valve. With regard to the flow properties, there are other clear advantages of the angle valve version. In general, due to their design, the Kv value of angle seat globe valves is higher than that of globe valves. The angle valve version of this new valve series, however, also has a flow comparable to angle seat globe valves.

Fewer elbow fittings are required for installation of the compact angle FlexPort Valve. This not only saves material costs, but also shortens the assembly time. Welds or joints are reduced, which in turn means that manpower can be saved. In addition, the valve is designed for various pipe angles and can be supplied with many standard pipe connections.

Cost advantages

If several or many valves are required for a skid or a plant, there are considerable cost advantages due to material and labour savings. The entire valve design is more compact and lighter. This is not only beneficial in terms of plant design, but benefits the plant operator as well, because he is not only investing in the cubic content, but also has to pay interest. Intelligently used, angle valves allow for a flexible, compact plant set-up that can save valuable space in each skid. In a large-scale plant or as a conceptual solution for the entire operation, several cubic metres fewer space is possible – a capital resource for the operator that should not be underestimated.

Wide field of application

The possible applications for FlexPort Valve solutions affect all industrial processes involving generation, treatment and supply. Examples include:

* Water treatment plants and pressure distillation.

* Plant peripheries such as process water and solvents supply systems.

* Heat exchangers.

* Heating and cooling of buildings, systems and machines.

* Cooling water systems for machine tools.

* Steam control for regulating moisture.

* Filling various media.

* Container cleaning plants.

* Textile cleaning plants and textile dyeing machines.

* Compressed air preparation and distribution.

* Smoke and steam control in food smoking plants.

* Pressure retention, temperature and volumetric flow regulation.

* Distribution of operating media such as welding gases or compressed air.

The valves are available in 90°, 135° (L/R) and 180° angles as standard. All other angles are also available on request. This gives plant engineers complete freedom of design. The nominal sizes are currently DN 15-50. Nominal sizes up to DN 100 are under development and will be completed during the course of this year. Because of the great operating temperature range, from -10 to +180°C, they can be used in almost any industrial application. The choice of connection includes threaded sockets, male threads, flange or butt weld spigots. The valves are delivered fully ready to install, are sealed and tested.

In addition to the valve itself, plant designers can rely on a complete range of accessory parts and instrumentation. The accessories range from Namur mounting brackets to stroke limiters and manual overrides through to optical position indicators with and without transparent cap. When it comes to instrumentation, Gemü electrical position indicators, pilot valves and positioners and process controllers are adjusted to the valves in the product range. With the FlexPort Valve, Gemü is offering a comprehensive package for valve configurations in skids and machine modules.

© Technews Publishing (Pty) Ltd | All Rights Reserved