Whether it is the shop floor or the accounts department, a company is made up of processes – a (hopefully controlled) series of actions that turn inputs into outputs. When those processes were designed, they had to address two principal requirements: what they must do and how well they must do it.

While it is easy to specify the first list, the second is a bit more of a problem. What are the performance criteria for turning an order into an invoice? Or, what is an acceptable production rate for orange widgets? If you do not know, the right thing to do is to guess – because controlled processes are self-adjusting. The wrong thing to do is to ignore the issue – and that is precisely why performance management is such a hot issue at the moment. Production managers, and others, have to set business-related targets and make sure that they stick to them.

Of course, they had always measured iron ore tonnages (for example) against set business targets but that is easy. What is not so easy is to find the root cause of why this target is not being met and what to do about it. Because of the hierarchical nature of processes and sub-processes, performance measurement must happen at all levels of the organisation and if it does not, you are trying to steer a ship without a rudder. Possibly while also trying to improve its engine performance so that you can get to where you do not want to be even faster.

Performance management is a huge subject that cannot be handled properly in one article alone. It is huge because it affects every activity of every company so we have to limit our scope somewhat and a good place to start is production and equipment.

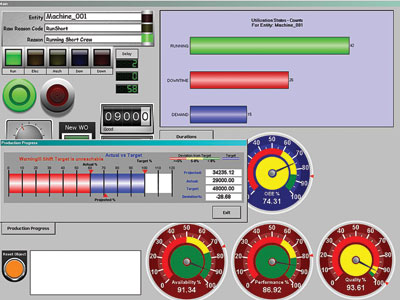

Solutions such as Wonderware’s Performance Software help manufacturing companies capture all of the critical equipment performance data they need to improve the capabilities of their productive assets to reinforce and drive lean manufacturing initiatives.

Using real-time plant performance information, decision makers and operators can help:

* Reduce capital expenditures by identifying the most productive assets for uninterrupted operation.

* Improve asset utilisation by identifying production bottlenecks more quickly.

* Increase the capacity of existing assets by pinpointing the causes of unplanned downtime to improve operational efficiencies.

* Leverage best practices, comparing line-to-line and plant-to-plant performance, including real-time Overall Equipment Effectiveness (OEE) measurements.

Drive more value from plant assets

Operating production equipment most effectively starts with high quality, real-time plant equipment downtime and efficiency data. Many companies use paper-based methods (or nothing at all) to track equipment downtime, efficiency, or assess the main reasons for production losses.

It makes sense that any performance measurement solution should integrate with existing automation systems to generate accurate and timely views of equipment performance. Short duration events, which typically never get recorded using paper systems, can now be ranked in order of importance. These events can add a significant downtime, but now they can be tracked pointing the way towards improvement. Automated equipment efficiency tracking quickly shows the plant assets that are being utilised effectively and those that are not.

No more personal opinions or ‘guesstimates’, just hard data on which to base decisions. With this higher level of insight, staff can quickly identify deficiencies and attack problem areas to unlock value from underperforming plant assets.

Knowing the efficiency or effectiveness of equipment is vital because it adds competitiveness and empowers operators to ‘take appropriate action’. Ignoring equipment effectiveness is not a viable option today, at least not for companies that want to keep a competitive advantage.

What to look for in a performance measurement solution

For equipment utilisation the solution should offer the ability to:

* Detect and capture utilisation events and automatically or manually assign reason codes.

* View equipment events.

* Monitor and record equipment state.

With regard to equipment performance facilities should be available to:

* Calculate OEE by equipment/line.

* Trigger events and display results.

* Analyse event frequency and duration.

* Assign what states affect the OEE calculation.

It should also be possible to monitor production progress in order to:

* Provide a clear indication of job or production order progress to the operator in real-time.

* Calculate OEE and other key parameters.

* Estimate expected completion date and time.

For more information contact Jaco Markwat, Wonderware Southern Africa, 0861 WONDER, [email protected], www.wonderware.co.za

© Technews Publishing (Pty) Ltd | All Rights Reserved