One of the biggest scientific trends of the 21st century

is centred on something incredibly small: nanotechnology. This is the engineering of functional systems at the molecular level and involves building sophisticated products on a nanometre scale. The technology is starting to be applied in a wide variety of fields, mechanical engineering being one.

Nanotechnology has enormous potential for innovation because it can create effects not possible with other technologies. One of the benefits is improved manufacturing. Familiar manufacturing systems can be modified to offer precision on the atomic scale. Control of systems can be expanded from the macro level to the micro level and beyond, while the associated costs are reduced. It is expected that molecular manufacturing will result in high quality, intelligent products that are cheap and efficient and have little environmental impact.

Rolling a wheel at the atomic level

The concept of a machine – a mechanical or electrical device that transmits or modifies energy to perform a certain task – can be extended to the nano world. The nanomachine components would be molecular structures, each designed to perform a specific task, which when taken together would result in a complex function.

Control of motion at the molecular level has already been achieved. Nanoscientists have built the first primitive artificial molecular motors, wheels and gears and demonstrated that energy consumption can be used to induce controlled and unidirectional motion. Linear and rotary molecular motors have been anchored to surfaces without loss of function. It has also been demonstrated that both linear and rotary motors can perform work and move objects.

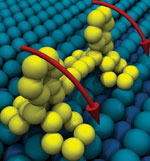

A European group of researchers has operated the first molecular rack with a pinion of 1,2 nm in diameter. Using trypticene groups they controlled the rotation of a 0,7 nm diameter wheel attached to a 0,6 nm-long axle in a molecule. This molecular 'wheel' could revolutionise machinery built at the nanoscale. It shows that rolling, a motion that is of fundamental importance in the macroscopic world, is also possible at the atomic scale.

Another group has developed a light-driven molecular brake resembling a tiny four-bladed wheel. Based on a rigid pentiptycene group which contains light-sensitive molecules, the paddle-like structure spins freely when a nanomachine is in motion. Exposing the structure to light changes its shape so that the blades stop spinning, in effect 'putting on the brakes'. The braking power can be turned off and on by altering the wavelength.

Designing and modelling nanomachines

On another front, atomically precise modelling of proposed nanomachines is rapidly growing more sophisticated. A young company called Nanorex has developed open-source computational modelling tools for the design and modelling of atomically accurate components and assemblies, and for simulating the properties of mechanical nanodevices.

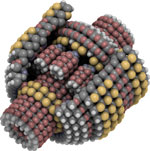

The Mark III planetary gear couples an input shaft via a sun gear to an output shaft through a set of planet gears attached to the output shaft by a planet carrier. The planet gears roll between the sun gear and a ring gear on the inner surface of a casing. Planetary gears are attractive targets for molecular modelling because the overall symmetry of the system virtually guarantees low energy barriers along the desired motion coordinate. They also pack considerable complexity into a small structure. Specifications of the Mark III are:

Number of components: 12

Number of atoms: 3853

Width: 4,2 nm

Height: 4,2 nm

Depth: 4,2 nm

Gear Ratio: 45:16

Speed Ratio: 2,8125:1

Output Torque: > 1x10–18 m-N

Angular Speed: > 10 GHz

Power: > 1 nW

Power Density: > 10 GW/cm²

Efficiency: > 99,8%

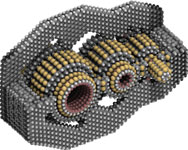

Another model simulates a parallel shaft speed reducer gear. This assembly includes a pinion gear, an output gear, and a silicon carbide casing which includes a pair of coupled bushings (front and back). This is complete with a casing and extended connector shafts.

Major challenges in the development of useful nano-machines remain. Researchers must apply their results to the design of complex nanomachines that really roll on a surface, transport atoms and are connected to other molecules. Goals will be the development of fast and repetitive movement over longer time frames; directional movement along specified trajectories; integration of fully functional molecular motors in nanomachines and devices; catalytic molecular motors; and systems that can transport cargo. As complexity increases in these dynamic nanosystems, mastery of structure, function and communication across the traditional scientific boundaries will be essential.

For more information go to http://www.nanowerk.com/spotlight/spotid=1516.php and http://nanoengineer-1.com/content

© Technews Publishing (Pty) Ltd | All Rights Reserved