Schneider Electric South Africa has announced its PlantStruxure architecture, a new collaborative system that allows industrial and infrastructure companies to meet their automation needs, and at the same time deliver on growing energy management requirements.

The system offers flexible, scalable and collaborative architectures that are the building blocks for manufacturing and process within the company’s comprehensive EcoStruxure energy management architecture portfolio. First announced late last year, EcoStruxure allows organisations to improve energy efficiencies across multiple domains of business including process automation, and connects five domains of expertise: power; data centres; process and machines; building control and physical security, within an open and flexible technology architecture that delivers up to 30% savings in energy efficiency.

PlantStruxure integrates both hardware and software components throughout the plant, delivering a complete process management solution that allows companies to optimise their energy usage and drive maximum efficiency within their operations while also improving productivity.

“Today, industrial companies face a multitude of challenges on different fronts, including increased competitive pressures, a volatile global economy, tighter compliance and regulatory requirements and higher costs of materials,” said Wilhelm Swart, industry and automation division, Schneider Electric South Africa. “To compete in this new world, collaboration and decision making based on actionable and relevant information is essential. PlantStruxure breaks down information silos with open, standards-based technologies to drive speed and agility, helping users gain a competitive advantage.”

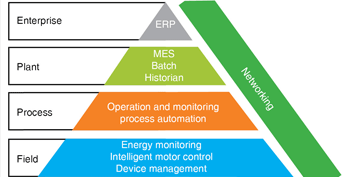

PlantStruxure allows easy collaboration between plant and operation managers, as well as engineering and maintenance teams through its powerful software suite combined with field proven hardware and open Ethernet-based technologies. PlantStruxure enables high process availability and offers redundancy and functional safety at each level of the architecture to meet the requirements of industries such as oil and gas, chemical, petrochemical, power and mining. Through architectures based on EcoStruxure’s intelligent energy management solutions, organisations that use PlantStruxure benefit from reduced project development, operation and production costs, while gaining real-time visibility of business performance, improved compliance and ROI.

“Traditionally, process automation systems, energy management systems, production management systems, and even plant design and engineering tools have each occupied separate domains. Manufacturers and the industry in general are increasingly moving to single environment encompassing production management, energy management and control systems functions as well as business information,” said Swart. “With PlantStruxure, Schneider Electric South Africa leverages its experience in the domains of automation, process control and energy management to deliver a system that provides a single architecture for all process control needs.”

Craig Resnick, research director of the ARC Advisory Group, authored the white paper ‘Schneider Electric deploys new PlantStruxure platform’. According to Resnick conventional approaches to process automation and operations management are evolving as processors and manufacturers demand enhanced visualisation, intelligence, control and agility, which require increased power and energy management capabilities. A collaborative framework, such as Schneider Electric’s PlantStruxure platform, will encourage the further breakdown of barriers to information by enabling a more comprehensive multidisciplined operational strategy, which in turn impacts productivity, responsiveness, lifecycle costs, energy efficiency, and most importantly, profitability.

To read Resnick’s full paper please visit http://instrumentation.co.za/+C14302

For more information contact Niconette du Toit, Schneider Electric, +27 (0)11 254 6400, [email protected], www.schneider-electric.co.za

| Tel: | +27 11 254 6400 |

| Email: | [email protected] |

| www: | www.se.com/za/en/ |

| Articles: | More information and articles about Schneider Electric South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved