Introduction

Traditionally, level measurements in power plants were made either using hydrostatic pressure principles which acquire the internal pressure in a vessel or by mechanical methods like floats and displacers.

Both methods have many disadvantages. Apart from operational costs, they require regular maintenance which impacts on plant availability and they introduce significant measuring errors due to their direct dependence on the medium.

The reason for these measuring errors is that the two principles are dependent on the density of the medium. The extreme temperature and pressure conditions in the boiler vessel change the density of the water, if the temperature increases, the density decreases.

Densities can vary by 600 gram per cubic centimetre when temperatures vary from standard to 350°C.

Disadvantages of floats and displacers:

* Wear and tear of moving parts requires maintenance.

* Build-up can cause float to stick.

* Changes in the density of the medium affect the accuracy.

* No indication if moving parts are stuck or drowned until overflow.

Disadvantages of differential pressure transmitters:

* Build-up results in inaccuracies.

* Changes in the density of the medium affect the accuracy.

* Fluids used as capillary fillings start boiling at high temperatures and low pressures.

An alternative reliable, level measurement can be achieved with the use of a non-contact measuring principle called time of flight using radar pulses. The sensor of a radar level transmitter acts as both a transmitter and receiver of radar pulses. The distance between sender and the medium surface is determined by the time of flight of the pulse using the known speed of propagation. The level may then easily be calculated taking the tank height into consideration.

The system of the guided microwaves offers a unique advantage in steam boiler applications. The microwaves are guided along the probe to the medium and are unaffected by medium properties.

Gas phase effect

If both steam and water coexist in the boiler, can the level of the water be accurately measured? The speed of propagation of microwave pulses in the gas phase is typically almost independent of changes in density and conductivity and it is determined by the dielectric constant of the medium.

Chemistry tells that polarised media (including water) change their dielectric constant with pressure and temperature changes, thus leading to a time of flight shift in the propagation of microwave pulses – often referred to as the ‘gas phase effect’.

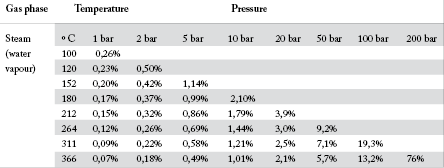

The use of standard guided-radar equipment without compensation of the gas phase effect can result in unwanted inaccuracies that lead to tedious adjustments by maintenance personnel with known references. The table highlights some errors that can be experienced without compensation.

Automatic gas phase compensation

Endress+Hauser’s Levelflex M guided radar transmitter automatically compensates the ‘gas phase effect’ using enhanced mechanical parts and software algorithms. The measuring system offers a unique advantage in that the compensation algorithm works independently of the operating point in terms of the process temperature and pressure.

In comparison to traditional, density dependent systems, an improvement in system accuracy by a factor 7 to 8 can be obtained in relation to a temperature change in water from 100 to 300°C.

The Levelflex M measuring device achieves this compensation by using a reference rod that is integral with the sensor rod. The reference rod generates a reflection which is at a known distance, in this way a shift in the reference reflection can be compensated for and the actual level reflection can be corrected by the compensation algorithm.

Additional features

The use of special ceramic seals allows use up to 400°C under 400bar process conditions.

Specific level measuring equipment has a safety integrity level (SIL) approval for overspill protection and other safety mechanisms in case of failure.

All Levelflex M measuring equipment is SIL2 rated as a standard.

The Levelflex M can be delivered pre-mounted in the bypass as one package, which reduces the shipping costs. This package, fully engineered by Endress+Hauser, includes selection and recommendation of bypass material and measuring technology. Various certifications are available and include:

* Pressure testing.

* Welding tests/inspection.

* Acceptance per DIN standards.

Performance testing and configuration are done prior to delivery and a multipoint calibration report can be provided if required.

For more information contact Lita Mpahlwa, Endress+Hauser, +27 (0)11 262 8000, [email protected], www.za.endress.com www.za.endress.com</a>

| Tel: | +27 11 262 8000 |

| Email: | [email protected] |

| www: | www.endress.com |

| Articles: | More information and articles about Endress+Hauser South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved