Fluid management is crucial in modern industry with the focus on optimising resources for maximum profit. As certain fluids are direct inputs into various processes, they are viewed as liquid assets and must be managed accordingly. In the agriculture market this is no different. Commercial farmers need to manage their resources better to optimise production in these tough economic times. Considering fuels, oils and liquid fertilisers as inputs into their process, the proper management of these liquid assets is vital.

Fluid management is crucial in modern industry with the focus on optimising resources for maximum profit. As certain fluids are direct inputs into various processes, they are viewed as liquid assets and must be managed accordingly. In the agriculture market this is no different. Commercial farmers need to manage their resources better to optimise production in these tough economic times. Considering fuels, oils and liquid fertilisers as inputs into their process, the proper management of these liquid assets is vital.

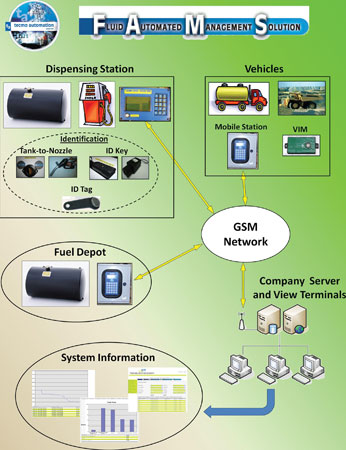

Tecmo Automation has for years been providing a fluid management solution called FAMS (fluid automated management system). The system provides a solution for fluid management in various market segments namely mining, fleet management and agriculture sectors. Specific fluids, which can be viewed as direct process-inputs in these markets, are diesel and petrol fuels, oils, lubricants and radiator coolant. As the need for the optimisation of resources has grown in all markets, the necessity for a FAMS solution has grown substantially. The FAMS solution for the agriculture market has evolved with time and need from the mining sector to a solution for smaller and different process such as the agriculture and commercial fleet management markets. A FAMS solution can provide the farming manager with the following features:

1. Automatic tank level management (LMS) – management of fluids in bulk tanks and automated electronic dip readings.

2. Fluid dispensing management – identification, authorisation and allocation of all dispensing transactions of fluids at depot filling points.

3. Vehicle information management (VIM) – automated vehicle and equipment information capturing and processing.

4. Data management software (DMS) – central data processing and reporting software system and client interface with alarming functions.

Tank level system or level management system

* Tank level measurement – done automatically via level sensor technologies (include ultrasonic and hydrostatic) and a tank level programmable controller.

* The controller has an integrated LCD for local data display.

* The controller has a GPRS/Ethernet/Serial connection to the central data management centre.

* The controller communicates all data to the central DMS where processing is done.

* Management software has an Internet-based client interface which is password protected and provides detailed reporting of various tank level information, statistics, alarms and exceptions.

Dispensing management with dispensing controller (DC)

* A programmable controller, or the dispensing station, with various built-in I/O, multiple serial, Ethernet and GRPS communication interfaces manages, captures and controls all dispensing transaction of fluids.

* A local LCD Display aids the user with respect to next actions to be performed and/or the current status of the process.

* Die-cast aluminium enclosure, IP65 and polycarbonate keys and display protection equates to a rugged operating platform for industrial environments.

* Local SD card stores all information which can be used for data auditing and back-up purposes.

* An integrated 2,4 GHz short range radio link to connect and communicate to VIM units and wireless tank level sensors.

* A Dallas I-Button interface and a port for an RFID reader allow the controller to identify users.

* All data is also communicated to the central data management software.

Vehicle information management

* Installed on vehicle and continuously captures vehicle/equipment parameters.

* Integrated GPS, short range radio designed for low power consumption applications.

* One x analog input port available for vehicle specific input.

* Parameters include: running hours, idle time, km’s travelled, maximum speed, average speed, acceleration etc.

Data management software

* DMS is an Internet-based client interface tool and available 24/7.

* Client data is username and password protected.

* Online data input facilities is available.

* All data is stored for the last five years, older data is archived.

* Various standard and customised reports available via Internet.

With the FAMS solution proper management of liquid assets in the agriculture market can now be easily done with consistently high levels of data integrity. This means better control by the business manager (in this case the farmer) of the use of products by the process to give optimal output. This gives operators in the agricultural sector access to technology which has been improving processes around the world for many years, enabling efficiency at the next level. For the farmer, it is time to break new ground in the information age.

For more information contact Francois Oosthuizen, Tecmo Automation, +27 (0)16 931 1958, [email protected], www.csdtecmo.co.za

© Technews Publishing (Pty) Ltd | All Rights Reserved