“The robotics market is characterised by heavy, expensive and unwieldy robots, so we decided to design and build a robot with universal appeal.”

This is how Enrico Krog Iversen, MD of Universal Robots describes the origin of the Danish company in 2003.

Background

At that time Kristian Kassow (now COO) was working on an analysis of the requirements for robots in the food industry. At the same time, Esben Østergaard (now CTO) and Kasper Støy were working on their PhD project about the market for robots. Together, they recognised that the robotics market is characterised by heavy, expensive and unwieldy robots.

With this insight they decided, with help from investor Syddansk Innovation, to establish Universal Robots, with the ambition of making robot technology available to all. In 2008 the Danish state investment fund saw the potential in the company and, together with Syddansk Innovation and the company’s management, invested DKK 10 million in the business.

Size counts

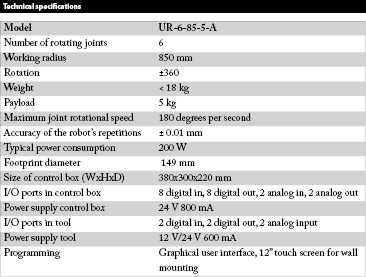

The UR-6-85-5-A robotic arm that Universal Robots has developed has a full six degrees of freedom of movement and yet it weighs in at a mere 18 kg and does not need a large space or heavy base for installation. In fact, on a recent visit to South African distributor Plasquip, Thomas Vermland of Universal Robots arrived from Denmark with a demonstration unit packed in two suitcases.

Small dimensions translate to large savings in the robotics market and Universal Robot looks like it will be giving existing robot manufacturers a run for their money where clients are looking for a robotic arm for handling loads of 5 kg or less in a working radius of 850 mm – especially in restricted areas.

Applications

One very typical application for the new robotic arm is in the handling of moulded parts from plastic injection and blow moulding machines. If a traditional Cartesian robot is used for such an application, the mould area becomes almost inaccessible to human operators because of the gantry structure, whereas the Universal Robots solution does away with this clutter and the arm folds back to allow easy access.

Another advantage that Plasquip sales director, Colin Whitaker, points out is that the robot really is portable – this means that in machine handling applications a single arm can serve one of several machines. Just move it to the machine where it is needed, when it is needed.

Programmability

Universal Robots has gone to a lot of trouble to ensure that programming is a simple task and does not require days of highly experienced technicians to successfully program a series of moves.

No separate software is required to program the robot – the graphical user interface programming software comes pre-loaded on the controller delivered with the robot and is operated via a portable touch screen which allows users to perform graphical programming and movement simulation before testing moves on the physical robot.

The programming system for this robot is extremely simple to use. In fact so simple that a basic palletising program can be set up in 10 to 15 minutes. This translates into lower Total Cost of Ownership than traditional robotic platforms.

Economics

Universal Robot’s flexible, industrial robots will enable owners to produce small batches at a very competitive price. Many project investments have achieved pay-back periods of as little as six months.

For more information contact Colin Whitaker, Plasquip South Africa, +27 (0)11 902 8923, [email protected], www.plasquip.co.za

© Technews Publishing (Pty) Ltd | All Rights Reserved