Using its Companion Rover GPS module and Allen-Bradley PLCs Hiprom has implemented a robust surface rail monitoring system for mines and various other rail yards.

A typical mine complex consists of numerous shafts producing ore for processing at one of many processing plants. Ore and consumables are transported within the complex by surface locomotives. These rail networks often span more than 50 km, making them some of the larger privately owned railways in Africa.

All rail operations are controlled by a single rail track controller in a central control room. In the past the controller had to rely on the locomotive drivers reporting their positions. As production grows, rail track is increased to the point where most operators decide to implement a surface rail control system in the interests of safety and improved efficiency.

System objectives

The objectives were to provide:

* Central visualisation:Display the exact location of each train in the central control room.

* Local visualisation: Equip each locomotive with a graphical interface.

* Proximity warning: Warn loco drivers of another train in close proximity.

* Collision avoidance: Automatically prevent collisions between trains.

* Speed limit enforcement.

* Improved overall operating efficiency of the rail network.

* A fail safe system.

System overview

The system consists of the following components:

* Rover units on each locomotive.

* Network infrastructure: base station communication infrastructure including repeaters.

* Control room.

Rover unit

The Rover unit:

* Calculates the locomotives' position and velocity.

* Determines which rail segment the locomotive occupies.

* Checks for speed limit violation.

* Checks if the locomotive is on a collision course.

* Trips the locomotive if necessary.

* Exchanges information with other locomotives and the control room.

* Provides information to its driver in a graphical format.

The Rover boosts on-board intelligence in the form of a Hiprom Companion Rover. The Rover is designed and manufactured by Hiprom as part of Rockwell Automation’s Encompass program. In addition to position, velocity and time data the module provides vital satellite and GPS receiver status information.

The entire rail network is digitised and programmed into the Rover. An algorithm uses the GPS coordinates to resolve the rail segment the locomotive occupies. It also uses the locomotive’s velocity to calculate the stopping distance and final resting place of the locomotive if it were tripped. The algorithm takes into account any forks (points) in the rails and thus there may be more than one possible resting place. After the algorithm has been applied to the local locomotive position and velocity, it is applied, in turn to all the other locomotives’ position and speed data. A collision is thus detected if any of the other locomotives’ final resting points overlap with that of the local locomotive. In this case the locomotive will automatically be tripped, and the brakes applied.

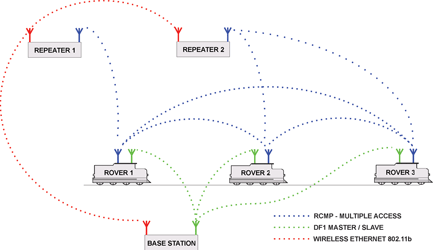

Communication is made possible via two UHF data radios. The rest is connected to one of the serial ports of the Rover, which is configured as a DF1 slave and is polled by the Allen-Bradley ControlLogix PLC at the base station. The second radio is connected to a Hiprom RCM communication module located in the Rover. The RCM module connects multiple RCM nodes in a synchronous, multiple access, peer-to-peer topology. This provides both a second method of exchanging information with the base station via repeaters and also direct communication with other locomotives.

All relevant information including current speed and speed limits is presented to the driver via a Hiprom touch screen terminal on which a map of the local rail network is displayed with his position and those of all the other locomotives.

Each driver must log in to the Rover before the locomotive can pull-off. This ensures that any operational violations such as excess speed are logged in the control room, against the correct driver.

Network infrastructure

To ensure complete data coverage over the entire complex two managed RCMP repeaters are used. The repeaters consist of a Rover and RCM module to which a UHF data radio is connected.

Each RCM module broadcasts its vital information in turn, within its allocated synchronised time slot. Every other RCM module in range receives the data, verifies its integrity and chooses to use or discard the information.

Each time one of the repeaters receives new information from a Rover it relays this information to the base station, by means of a wireless Ethernet link.

The rover requires position and velocity information about all the other Rovers, in order to detect a pending collision. The redundancy of having two separate communication networks provides for a reliable robust system.

The base station consists of an Allen-Bradley ControlLogix PLC and DF1 UHF data radio, which is responsible for marshalling relevant information between the Rovers, repeaters and the scada system.

Control room

The central control room consists of two RSView scada nodes. One of the scadas is connected to a large format projector providing the rail track controller with a view of the entire complex.

The rail track controller can zoom in to specific areas and view all the details of a specific Rover by clicking on its associated icon.

RSView logs all information to an MS SQL database. This information is used to generate exception reports and to provide a graphical play-back facility to analyse events.

For more information contact Hiprom, +27 (0)11 787 4458, [email protected], www.hiprom.com

© Technews Publishing (Pty) Ltd | All Rights Reserved