ArcelorMittal’s Newcastle bar mill replaces its obsolete scada facility.

ArcelorMittal’s Newcastle bar mill replaces its obsolete scada facility.

South Africa’s leading supplier of profile steel products turned to Wonderware’s solution to improve control and facilitate process setups.

The old system at the mill consisted of two Gem80 Multigem operator interface systems with two Imagem scada systems and a GEC micro VAX, which stored the 400 different product recipes.

“In order to improve control and fabrication setups, it was decided to replace the obsolete Gem80 with new technology,” says Jan Calitz, electrical technologist at ArcellorMittal’s Newcastle works. “We went out to tender for the mill operator interface (MOI) system conversion but eventually decided to implement the system in-house which resulted in a significant saving.”

Solution selection

“For the scada and HMI we selected Wonderware’s InTouch because of its ease of use, regular updates and the speed with which changes can be implemented. For the PLCs we chose Fanuc because it was the only manufacturer that had a Gem80 ESP driver to communicate to the 45 GEC micro DC drives. Automation Design Systems translated the Gem80 code for the Fanuc PLCs.”

System architecture

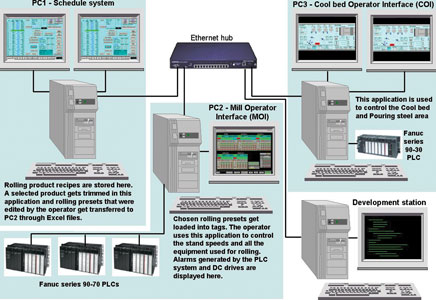

Figure 1 illustrates the system topology. The GEHCS (Wonderware GEFanuc Ethernet Server) server is used to communicate with the four Fanuc PLCs and the three InTouch stations. An isolated Ethernet network was installed to keep the control network separate from the business network.

Each workstation uses a Brodersen I/O pack connected to supply the desk I/O, control some water valves and read the temperature of the bar being processed at certain points.

Implementation

The project was implemented in phases over a period of four years. “The only way to get there was through combining an in-depth knowledge of the bar mill processes to be controlled with an understanding of the technologies at my disposal,” says Calitz. “I used the Wonderware Support Users’ Forum continuously during development and got a lot of assistance from Wonderware Southern Africa.”

The three InTouch-based applications were written from scratch with the screen presentations kept as similar as possible to assist the operators.

The Schedule InTouch application stores the recipe database for the 400 products manufactured at the mill. These recipes contain the rolling schedule information as developed by the mill’s Roll and Tackle department. The operator selects the product to be rolled and adjusts the final speed and the different rolling stand roll diameters. These parameters are then gets transferred to the MOI InTouch application for control of the plant.

The MOI application is connected to the three Fanuc 90/70 PLCs and also controls the 27 stand mill motor speeds as well as some ancillary equipment. This system also supplies the COI application with some preset data via SuiteLink.

The cool bed operator interface (COI) InTouch system controls the cool bed and pouring reel area PLC via GEHCS connected to a Fanuc 90/30 PLC. The COI system has 15 rolling schedule setups grouped together. The operator selects which group is to be used for the rolling process and then transfers these settings to the control system.

Benefits

* A saving of R6M was realised through the in-house development of the Schedule and MOI applications.

* The mill can now run 16% faster, which translates into an additional prime output of 16 000 tons per annum.

* The new system is operator-friendly and setups are easy to implement.

“Changeover from the old to the new system was done with no production time loss and the operators find this system very user-friendly,” concludes Calitz.

For more information contact Jan Calitz, ArcelorMittal South Africa, +27 (0)34 314 7525, [email protected], or Justin Tweedie, Wonderware Southern Africa, 0861 WONDER, [email protected], www.wonderware.co.za

© Technews Publishing (Pty) Ltd | All Rights Reserved