In March 2007 an important piece of South African legislation was published that affects all manufacturers, importers, users and repairers of explosion protected apparatus (EPA). The provisions of this 'Recommended Practice' became effective six months later.

Health warning and disclaimer

The initials ‘ARP’ stand for Aanbevole/Recommended Practice – but this term is misleading – there is nothing optional about compliance with ARP 0108, it is a legal requirement.

This article is based on the author’s interpretation of the document and does not remove the requirement for readers to fully familiarise themselves with the contents of all relevant and associated legislation.

ARP 0108 in a nutshell

Introduction

ARP 0108: 2007 Edition 1.01 – 'Recommended Practice – Regulatory requirements for explosion protected apparatus' was published by the South African Bureau of Standards on 2007-03-26 to replace the existing ARP 0108 and is for use in conjunction with SABS 0108:2005 – 'South African National Standard – The classification of hazardous locations and the selection of apparatus for use in such locations'.

The ARP is described as a sectoral technical agreement and was developed in conjunction with a list of industry players including various local electrical manufacturers, the CSIR, the Department of Labour, the Department of Minerals and Energy, industry bodies including the Electrical Contractors Association of South Africa and the S A Flameproof Association, the SABS and significant end users such as Sasol.

Although the ARP covers both surface and underground application of EPA the ultimate responsibility for the accuracy and updating of the document falls under the ambit of the Department of Minerals and Energy.

Normative documents

There are nearly 60 references to normative (see below for meaning) documents, including standards issued by AS, ATEX, CSA, FM, IEC and UL. Through their reference in the text of ARP 0108 these standards constitute provisions of the legislation.

EPA product conformity

Product conformity for explosion protected apparatus is based on:

* Type testing.

* Batch testing of production units (unit verification).

* Production under an approved certification scheme (quality assurance).

The minimum requirements for type testing or batch testing are:

* The application of an approved standard.

* That the testing is performed by an ATL (approved test laboratory).

* A type test certificate (for type testing) or a batch test report (for batch testing).

The controversy – Part 1

The first controversial requirement is the annual re-certification of EPA where local certification by an ATL is based on original overseas certification.

Annexures A and C of the ARP are designated normative (see below) which means that they explicitly require compliance. The controversial requirement is found in reading A.1 and C.2.

A.1 requires that, “… all new EPA requires a certificate issued by an ATL.” It goes on to say that such certificates are normally based on approved national standards (which are listed) and continues, “… However, certificates in terms of the standards listed in column 3 of table A.1 may be used as a basis for issuing [an IA certificate]. No local testing will be required in terms of column 3 …” and proceeds to detail the criteria under which local testing is not required.

The ARP refers readers to the SANAS website for a list of current ATLs and their respective scopes of accreditation.

Column 3 of table A.1 – “Approved standards, test laboratories and certification bodies for EPA” reads like a ‘Who’s Who’ of internationally recognised standards bodies and the list includes AS, BS, CSA, EN, FM, IEC and NFPA.

C.1 requires that all EPA used in Group I (underground mining) and Group II (surface applications) has an IA certificate.

C.2 says that “All IA certificates shall have a validity period of 10 years. Where a product is in service and its certificate expires it will not be affected.” The ARP then immediately contradicts itself by saying that IA certificates based on overseas certification will only have a validity of one year.

C.8 requires that an EPA that is still in production be submitted to an ATL for re-certification prior to expiry of its current IA certificate so that re-certification is achieved before expiry.

The ARP specifies which parties are responsible for compliance with the various clauses of Annex C. Readers should particularly note:

C.1 is the responsibility of Manufacturer or supplier, User and ATL;

C.2 is the responsibility of Manufacturer or supplier, User and ATL;

C.8. is the responsibility of Manufacture or supplier.

Who are the ATLs?

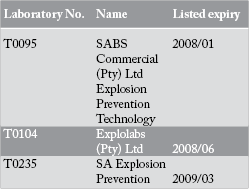

The SANAS website listed the following ATL details when accessed at the end of August 2008:

A spokesman from one of the ATLs told SA Instrumentation and Control that SANAS had experienced delays in finding a suitable auditor to review the ATLs. This had resulted in some accreditations expiring. The spokesman also said that there is an ongoing problem with SANAS not keeping its web listings up to date.

The relevant heads of SABS Commercial had failed to respond to our written enquiry by the time this article was written.

ARP 0108 – The idiot’s guide

So, in layman’s terms, this is the author’s analysis of what the introduction of ARP 0108 1.01 means to each party.

Users

Users need to ensure that they receive an IA certificate issued by an ATL for all EPA that they have received since September 2007. Once the EPA is in service there is no need to renew the IA certificate.

Users must also make sure that each piece of EPA carries a label with details as specified in the IA certificate. For instance the author had sight of the following labelling requirement called for in an IA certificate:

Supplier: [IA applicant’s business name]

IA Number: [IA certificate number]

Rating: See Table [n]

User compliance is complicated by the fact that a user can now have, for example, two apparently identical EPA items (Model [XYZ] barriers) imported one year apart. Whereas in the past the two would have fallen under a single overseas certificate, they will now fall under two different locally issued IA certificates. Unfortunately, the wording of the locally issued certificates in terms of serial numbers typically reads along the lines of, 'All items imported between Issued and Expire dates'. This implies that users will now have to implement a register to correlate specific serial numbers of EPA with their associated IA certificates. However, DME/DoL inspectors will have no way of verifying this information.

Unfortunately the ARP does not define the term 'in service'. This is a significant omission. Users must ask themselves what happens when they have a spare EPA in their stores. This can hardly be viewed as in service. If the EPA received its IA certificate through re-certification by a local ATL of an overseas certification does the user have to apply for re-certification after the EPA has been in the country for more than one year?

Multiple telephonic and written approaches by SA Instrumentation and Control to the Department of Minerals and Energy over a three week period failed to elicit a single reply, so we will have to leave readers in the dark on this question for a while.

User purchase price of EPA are likely to rise significantly.

SA EPA importers

Along with users, this group is most affected by the introduction of ARP 0108.

Whereas pre ARP 0108 1.01 all they required were certificates from an approved overseas test body, they now need to have an EPA which they import either tested or, as a minimum, re-certified by the ATL oligopoly. This is proving time consuming (importers say that the process is taking three months or more in many cases), expensive, adds further administrative burden and has unconsidered consequences.

And this is an annual requirement – so assuming a supplier imports series XYZ EPA widgets on a regular basis he should have obtained an IA certificate for that EPA or EPA series from one of the three ATLs prior to September 2007 and would be due to apply for the second re-certification prior to expiry of that first certificate.

Importers carrying stock face the same uncertainly as users when considering the one-year expiry of IA certificates for their stock holdings (EPA not in service).

One of the unconsidered consequences of the local marking requirement is that importers now have to break tamper-evident seals of EPA to apply the local markings. This means that stock can never be returned to the original manufacturer – since that manufacturer, from a safety perspective, is obliged to view such equipment as having been used. Retesting to standard would be prohibitively expensive and hence such a returned EPA has to be destroyed.

Ultimately the consequential costs of compliance are passed on to the end user who in turn passes it on to the consumer, contributing to the inflation spiral.

SA EPA manufacturers

This group is probably least affected.

Their certification cycle would be along the lines of:

Design the EPA, manufacture some prototypes, submit detailed designs and samples for either type or batch certification to an ATL, pay the ATL fee and on successful testing by the ATL receive an appropriate type or batch IA certificate with 10 year validity.

ATLs

At first glance the three ATLs seems to benefit the most from the introduction of the revised ARP 0108; they have the windfall of the initial re-certification exercise (satisfying themselves with the credentials and paper trail from the original overseas certifier) as well as a new, and guaranteed annuity stream within an oligopoly.

An ATL scorecard

There is an understandably high level of emotion in the industry – both at user level and at the importers – surrounding the introduction of the revised ARP. But the overall feedback that the author received from these two groupings is that the ATLs are not performing.

In particular the feeling is that the ATLs:

* Overcharge.

* Underdeliver.

* Do not have the capacity to perform the certification/re-certification.

In writing this article SA Instrumentation and Control had sight of IA certificates that surely fall short of the spirit of ARP 0108:

* A certificate failing to even mention a model or series number.

* Requirement to mark Rating as 'See Table [n]'.

Sources:

ARP 0108 – Standards South Africa

Abbreviations

ARP Aanbevole/Recommended Practice

ATL Approved test laboratory

DME Department of Minerals and Energy

DoL Department of Labour

EPA Explosion protected apparatus

SABS South African Bureau of Standards

SANAS South African National Accreditation System

Resources

SABS www.sabs.co.za

SANAS www.sanas.co.za/directory/test_default.php

Definitions

Approved test laboratory (ATL) – a test laboratory that is accredited by SANAS and appointed by the relevant approving body (in this case DME, DoL/OHSA) to carry out tests specified in the relevant standards and to issue certificates (known as IA certificates) for EPA indicating that the apparatus complies with requirements of the approving authority.

IA certificate – a national certificate issued by an ATL endorsing conformance with the relevant national standards.

(Paraphrased from SANS ARP 0108 1.01)

About the author

Andrew Ashton has electrical, mechanical and business qualifications and has been active in automation and process control since the early 1980s. Since 1991 he has headed up a company that has developed formulation management systems for the food, pharmaceutical and chemical manufacturing industries and manufacturing solutions involving the integration of various communication technologies and databases. Developed systems address issues around traceability, systems integration, manufacturing efficiency and effectiveness. Andrew is features editor for SA Instrumentation and Control and editor of Motion Control in Southern Africa.

Part 2 of this article will appear in the November issue of SAI&C.

© Technews Publishing (Pty) Ltd | All Rights Reserved