An element of the smelting operation at Lonmin’s facility in Marikana involves drying platinum group metals concentrate through filtering and flash-drying processes. With platinum at an all-time high on world markets, production stoppages and inefficiencies could no longer be tolerated.

“The filter and drying section of the plant was identified as the bottleneck for the smelting operation,” says Frans de Beer, senior manager, Smelter. “We limited our furnaces accordingly because the concentrate could not be dried fast enough. Project leader, Kevin Hayes, did a black belt six-sigma project on the drying plant and another on the filtering plant but we could not get definitive results. Checking on the variances between these plants, however, showed that they were working against each other. This meant that we had to integrate the filter plant with the drying section.

“One way of doing this was to decouple them, introduce a storage facility and run them separately. Another was to introduce APC to effectively decouple them but to leave the plant unchanged. This was the preferred option and that is why we chose CSense.”

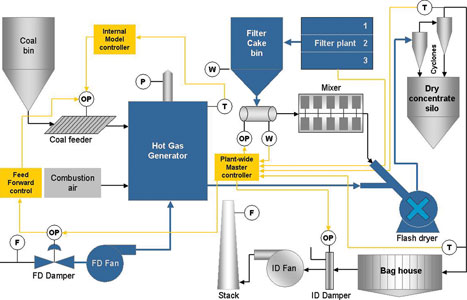

The overall control system objective was broken down into three parts, as follows:

* Optimal control of the hot gas generator (HGG) temperature.

* Optimisation of HGG fluidising damper control.

* Maximisation of flash dryer throughput.

HGG temperature

Poor control of the HGG temperature, a result of complex process dynamics, impacted negatively on flash dryer throughput as heat generated in the HGG was oscillatory and under certain conditions resulted in trips or the interruption of fuel feed. By implementing more stable temperature control these problems were eliminated, maximising both up-time and throughput.

luidising damper

Control of the fluidising damper was performed by the operator prior to APC implementation. It was shown that the damper was often operated sub-optimally resulting in either not enough, or an excessive amount, of heat being generated for the amount of filter cake available for drying.

Flash dryer throughput

“Controlling the temperature of the flash dryer was one of the main challenges as it is affected by the feed-rate as well as the moisture content of the incoming material,” says Percy French, automation manager, Smelter. “Another problem was having the filter section keep up once the flash dryer was properly controlled. So we looked at the data sets and started to build the control model, as described in the six-sigma project, and this served us well when implementing CSense.”

Prior to APC implementation, the operator would select the set-point for flash dryer feed rate based on expected available filter cake. Due to the small size of the filter cake reservoir this often led to either the bin running empty, which resulted in too high flash dryer temperatures that tripped the flash dryer; or the bin staying full, which held back filter production. Dynamic process models of individual equipment in the drying plant were extracted from historical process data. These models were then used to construct a dynamic plant simulation, from which an optimal APC control system was designed.

Benefits

* Production has increased from 16 000 tons/month to over 20 000 tons (although other factors have also contributed.)

* The initial claim was that CSense could improve production by 10% but the real number is well above that yet difficult to isolate precisely because of the interdependencies of the processes involved.

* Operators no longer have to worry about changing set-points and can focus on other problems.

* Incorrect temperatures due to bad control practices are a thing of the past.

* CSense was easy to integrate with the current control system and its rules can be changed just as easily by authorised end-users.

* By eliminating uncertainties, CSense has helped Lonmin to focus on the next level of productivity challenges.

In an increasingly sophisticated manufacturing and mining world, APC has become a differentiator between profit and loss, cognitive control and make-do control, predictability and trial and error. APC is a mechanism whereby the intellectual property of operators and process managers can be captured and refined to solve increasingly complex problems.

For more information contact Johan Rademan, CSense Systems, +27 (0)12 347 3110, [email protected], www.csensesystems.com

© Technews Publishing (Pty) Ltd | All Rights Reserved