Wonderware panel computers help SAB streamline Alrode Brewery’s packaging lines

At SAB's Alrode brewery, the largest deployment of control panels is in the packaging halls. They are normally provided by OEM vendors who supply either individual packaging machines or complete packaging hall solutions. Packaging lines have a long lifespan and machinery is upgraded over time. However, it is quite common for the machinery to outlast the interface supplied with it. Panels chosen to satisfy current packaging requirements at the minimum cost are often preferred, since profitability is maximised.

The problem

One of the consequences of this approach is that end-users can be required to maintain a wide variety of disparate platforms that have no clear software upgrade strategy and are often based on old operating systems that are difficult to support. The same applies to human machine interfaces (HMIs) that conform to different visualisation standards and which add another layer of complexity with respect to the maintenance strategy - stocking spares for up to 10 different panel types in the case of SAB's Alrode brewery. Additional complexity is added when implementing disaster recovery procedures, even simple changes to accommodate new business requirements may require rework by the original supplier.

"This all adds up to quite a mission, especially when one considers that we have five packaging lines with up to 20 panels per line," says Darryl Oelofse, technical manager at SAB's Alrode brewery. "But that is not the end of the story. The pace at which panel technology is advancing can, within four to five years, leave end-users in a situation where they are employing panel technology which can no longer be supported. What is lacking is a clear upgrade strategy that will allow packaging lines to be integrated to cope with the company's changing business needs. This leaves it up to end-users to upgrade their panel technology to suit their needs."

SAB decided to tackle the problem. During the solution evaluation phase it became apparent that purchasing decisions should not be based simply on hardware technology but on how the chosen solution would add real business value since a substantial investment was involved.

Business requirements

* Redundancy - typically, each packaging machine is supplied with an individual panel that controls only that machine with the result that the failure of any panel would bring the entire packaging line to a halt. This lack of redundancy is a leading cause of downtimes from panel and network failures.

* Uniform operator interface - since each current panel was using a different visualisation standard, the chosen solution must provide a consistent operator interface to reduce complexity and it allows for the easy training of operators. "For example," says Oelofse, "if one moved an operator from a packaging filler on one packaging line to another the operator had to be retrained on how to use the interface. This restricted our ability to re-deploy people."

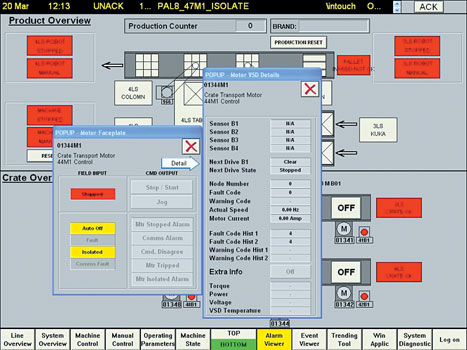

The viewing of other process areas - the ability of the new system to integrate multiple data sources and provide access to other areas would result in quicker, proactive problem diagnosis and solution as well as reduced communication gaps and downtime.

* The ability to run multiple applications - in order to eliminate the need for application-specific workstations, one standardised platform was required that would allow the deployment of many value-added applications.

* Realtime performance monitoring - system operation needed to be interactive, allowing operators to proactively manage the performance of packaging lines.

* Alarm distribution - a unified and standardised approach would allow for alarms to be displayed on all controllers.

* Future-proofing - "It was a top priority that the chosen solution must lend itself to easy upgrades and enhancements without the necessity to invest in new hardware or re-engineering software applications as in the past," says Oelofse. "We had to have a technology that we could easily integrate into the rest of our business and that could run our standard business software."

The solution

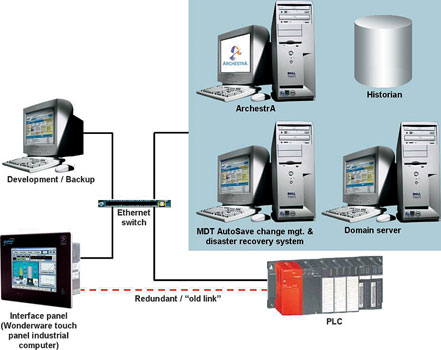

To address the above requirements, SAB chose Wonderware industrial touch panel computers, which were ArchestrA-ready and pre-configured with the InTouch HMI/SCADA application. Oelofse says that this choice was made for a number of reasons, the most important one being the ease with which these panels could be seamlessly integrated into SAB's network, operating systems, security systems and the rest of their manufacturing and business support systems. "The Wonderware panels are based on modern technology and operating systems which constantly move with the times so that we would not get stuck in dead-ends as has happened with some of our other panel technologies," says Oelofse.

From a redundancy point of view, SAB developed a tool kit for the software that enabled them to construct similar-looking interfaces with similar standards for all I/O, alarm messages and the whole environment, which provided for the merging of applications. This also allowed the merging of similar machines into a single application that not only reduced the number of panels but also allowed the operator to work from a single panel. Furthermore, if a panel failed, the operator could move to another panel and view his application from there.

"We did not migrate packaging lines to the new technology all at once," says Oelofse. "This was to be a gradual process but we had a vision that we would ultimately be moving to ArchestrA and a single packaging application per line with all the software engineering economies and convenience this would provide - and so all development was done with this in mind. We also adopted many of the SCADA standards that we had already developed for the rest of the plant but adapted them to the packaging environment."

The accrued benefits

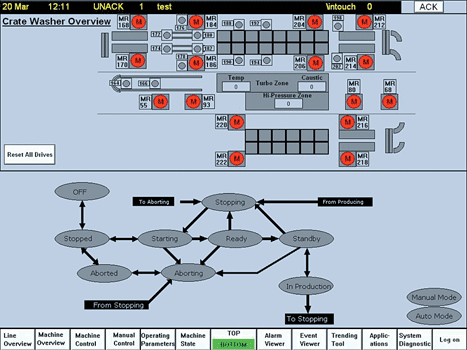

* Uniform and standardised operator interface irrespective of the packaging machine involved (Figure 2).

* Reduced maintenance and upgrade costs of control panels.

* Redundancy throughout by being able to run any application from any panel.

* Better operator control through access to the status of other processes.

* Uniform attendance to alarms.

* Freedom from OEM proprietary products.

* Expandability and upgradeability through the use of standard software and operating systems.

* Solution is aligned to SAB's business needs.

* Unified approach to packaging line control and performance management.

For more information contact Justin Tweedie, Wonderware Southern Africa, 0861 WONDER, [email protected], www.wonderware.co.za

© Technews Publishing (Pty) Ltd | All Rights Reserved