Automated test engineers face pressure to increase return on investment (ROI) from two seemingly contradictory sources.

These engineers are challenged to decrease the cost of test systems and, at the same time, reduce the amount of time needed to implement these systems. As test engineers lay out their strategies to increase ROI, developer productivity is one of the biggest opportunities for cost and time savings. Of all the costs involved in creating a test system, development time - the engineering resources needed to create the test system - accounts for more than 30%.

Two of the most effective strategies used to increase developer productivity are the emphasis on modularity in the software architecture and the use of commercial off-the-shelf (COTS) software. Modularity increases the re-usability of the software while facilitating its maintenance, and by using COTS software engineers can use prebuilt development tools provided by a vendor. With the economies of scale created by the vendor, COTS software is more cost-effective and higher in quality.

Test software architecture

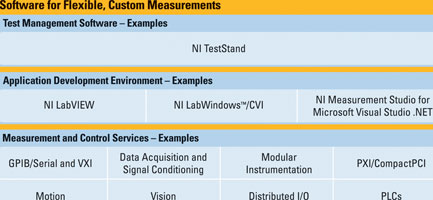

Historically, engineers have built test systems from scratch using a monolithic architecture in which all components were fused together, significantly limiting system maintainability and re-usability. Today, engineers can use a modular software architecture, which consists of three hierarchical layers - test management software, application development environments, and measurement and control services - as a way of meeting these challenges.

Test management software layer

Test management software, the highest layer of the modular software architecture, brings together the other two layers to develop a complete test system. By using COTS test management software and a modular software architecture, engineers can re-use the modular components of the architecture and maintain each of the pieces independently, improving developer productivity.

One of the biggest benefits of COTS test management software is a development environment designed for performing tasks at the architectural level of test system development.NI TestStand 4.0, the latest version of the National Instruments test management software, emphasises improving developer productivity with the newly redesigned Sequence Editor development environment. The new Sequence Editor consists of reconfigurable panes for easily defining the look and feel as well as the functionality of the development environment.

The Sequence Editor also includes the Insertion Palette, which engineers can use to quickly create new steps by dragging and dropping them into a sequence. By displaying all the different steps available, instead of hiding them under different menus as in previous versions, engineers can more easily understand all available functionality in NI TestStand.

The Insertion Palette can also store and re-use preconfigured step templates. These templates decrease the amount of time engineers need to develop test sequences by facilitating the re-use of existing test elements.

In addition, the new version of NI TestStand includes tools that further improve productivity by facilitating everyday tasks, such as the ability to call the NI TestStand engine directly from Expressions - the output window, which engineers can use to easily post debugging and event messages during execution - and the ability to use Expressions for test limits. The new version of NI TestStand also includes tools to develop custom Sequence Editor development environments.

NI TestStand 4.0 improves enterprise system connectivity and reporting through requirements management integration, the sequence file translator framework and the new XML and binary sequence file formats. The new version of NI TestStand reduces the amount of time necessary to trace requirements stored in requirements management systems, such as Telelogic DOORS, to their implementation in NI TestStand sequences. The sequence file translator framework, included with NI TestStand 4.0, increases ROI for engineers who must define their tests using industry standards such as the Automatic Test Markup Language (ATML). This framework facilitates test system integration with these custom test description formats by providing tools for creating translators that automatically convert custom test descriptions into NI TestStand sequences. To increase the integration of default NI TestStand test sequences with enterprise systems and applications, National Instruments added the XML sequence file format to NI TestStand 4.0, which is more readable by developers and software applications.

Application development and measurement services software layers

Engineers can significantly increase ROI in the next two layers of the modular software architecture - application development environments and measurement and control services. Because of the ever-increasing role of application software in test system implementation, providing an application development environment (ADE) such as National Instruments' LabVIEWandLabWindows/CVI that increases test developer productivity is critical to increasing ROI. In addition, based on the significant amount of time engineers spend debugging instrument communication and driver issues, it is important when building a test system to use measurement and control services software, such as NI Measurement & Automation Explorer, that offers interactive debugging tools and test panels as well as the ability to communicate between application software and hardware.

From the measurement services layer to the test management layer, there is always an opportunity to increase developer productivity and reduce costs. Whether using COTS software such as NI TestStand for test management or additional measurement services with driver software, engineers can increase developer productivity and ROI using the right tool for each layer of the test system software architecture.

For more information contact National Instruments South Africa, +27 (0)800 203 199, [email protected], www.ni.com/southafrica

© Technews Publishing (Pty) Ltd | All Rights Reserved