Battery powered utility water meters

October 2007

Flow Measurement & Control

In a large consumer meter environment, monitoring both flow and pressure and alarming on these two variables, can significantly contribute to water demand management, water balancing, as well as managing the risk associated with high pressure water bursts.

Supervisory and Control Expertise won a contract to supply a battery driven, flow and pressure monitoring and alarming system for mainly mechanical water meters for Rand Water. Due to where water meters are normally located, line of sight for radio and cellular signal strength cannot be guaranteed. More than 200 of these devices were successfully installed, using cellular technology, and the system has been running for nearly a year.

From experience we knew that GSM-SMS communication works more effectively than GPRS in low signal strength areas, and we opted to activate only the SMS communication on our cellular device. The system was installed over the total supply area of Rand Water, and there is not a single site that is not reporting (though some have pretty weak signals <10% of full strength)

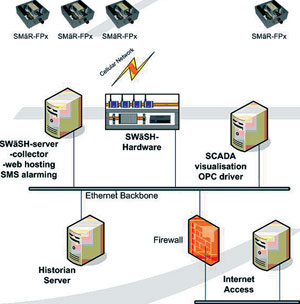

The units installed in the field are called SMãR-FP-units, and stand for (SMS monitoring and alarming remote unit - for flow and pressure). These units are IP68 rated, and can have external or internal antennas for operation in submerged conditions.

Figure 1. The SMãR-FP-unit installed for monitoring and alarming on flow and pressure

Monitoring functions

* Can be remotely configured to record flow volume and pressure at between 5 and 60 minute intervals.

* Units can be synchronised to the reading on the flow meter.

* When the buffer is full, the recorder data is sent to a server computer, where it is made available in both OPC and written into an SQL-type database for trending and reporting.

* An option for advanced graphing like statistics, summation, etc, is available for analysis.

Alarming functions

* High, low and sudden change alarms for pressure are generated in intervals of 1 minute, and alarms immediately sent to the central server for action.

* High, low and sudden change alarms for flow are also generated.

* Tamper alarm on trying to remove the box is generated at any time.

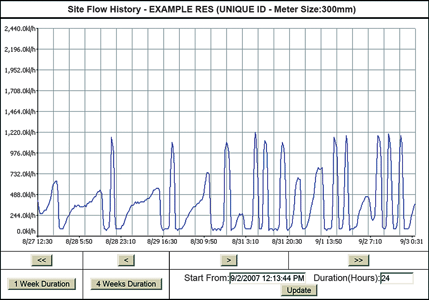

Figure 2. The SWãSH-server interaction with other systems

Server functionality

To manage all the information and distribute alarms and facilitate interfacing to other systems, the SWaSH-server has the following functions:

* Capturing data from the SMaR-FP-units.

* Sending SMSs for alarming purposes to pre-configured addresses.

* Storing and making available data and information.

* Insert trend and alarm information into Industrial SQL database.

* Configuration of parameters for monitoring and alarming functions.

* Hosting an OPC Server (DA versions 1, 2 and 3 compliant) for access to current data and alarms. This is a two-way interface which allows configuration of certain operational parameters as well as acknowledging of alarms from for instance a scada environment.

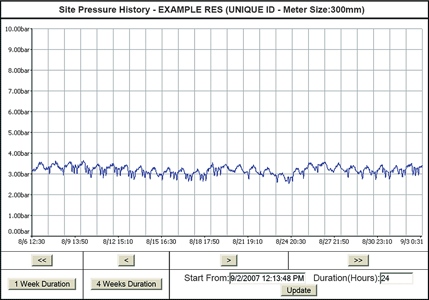

Figure 3. Example graphs with flow and pressure information for the same reservoir for four weeks

Typical information from the system

Each meter has a status screen with last meter reading, flow, pressure as well as alarms. Shown above is a typical 4-week graph for pressure and flow for reservoir.

For more information contact Jaco Hoogenboezem, Supervisory and Control Expertise, +27 (0)16 982 3700, [email protected], www.sce.co.za

Further reading:

Mastering inline LNG flow monitoring

Flow Measurement & Control

[Sponsored] As global demand for cleaner, more flexible energy sources continues to rise, liquefied natural gas (LNG) stands at the forefront of the energy transition. Engineered for excellence in cryogenic environments, the Anton Paar L-Cor 8000 flowmeter redefines inline LNG flow monitoring.

Read more...

Magnetic-inductive flowmeter with effective compact electronics and IO-link

Instrotech

Flow Measurement & Control

KOBOLD has combined two of its proven components, the successful type MIK magnetic-inductive flow meter and the popular U-PACE compact electronics, creating an exciting new compact flow instrument at the best price.

Read more...

Dosing chlorine gas safely and sustainably

Flow Measurement & Control

Chlorine gas is central to a range of industrial processes but is highly dangerous. The solution is the deployment of a system solution for chlorination from Lutz-Jesco.

Read more...

Oil monitoring solution drives performance gains for paper mill

SKF South Africa

Flow Measurement & Control

By integrating real-time monitoring with precise flow control, SKF’s Flowline oil monitor meters have significantly improved the flow rate control and performance of oil circulation lubrication systems installed on a paper mill.

Read more...

Flow measurement in mobile applications

ifm - South Africa

Flow Measurement & Control

The SU Puresonic Mobile ultrasonic sensor from ifm is characterised by its displayless design and high temperature resistance. It is ideal for mobile applications and processes with permanent media temperatures of up to 120°C.

Read more...

Optimising water quality in a building cooling system

ifm - South Africa

Flow Measurement & Control

A leading company in industrial water management has installed water treatment systems that not only optimise water quality but also help customers to improve their processes, thanks to the new insights and actions that can be generated based on the process data collected.

Read more...

New uncompromisingly simple flowmeter line for processes

Endress+Hauser South Africa

Flow Measurement & Control

The demand for simplicity in commissioning, operation and maintenance in industrial process plants has increased significantly in recent years. The new Proline 10 range of flowmeters from Endress+Hauser meets this requirement without compromise, because simplicity is the top priority.

Read more...

Rotork joins Rockwell Automation’s Technology Partner Programme

Flow Measurement & Control

Rotork has entered into the Rockwell Automation Technology Partner Programme, marking a significant step in expanding the company’s presence within the industrial automation landscape.

Read more...

Loop signature 29: Averaging or surge level control

Editor's Choice Flow Measurement & Control

There are many processes where it is undesirable for the load to suddenly change quickly, for example in the paper industry. Examples of level control have involved reasonably fast tuning. An example of a level loop tuned this way and responding to a step change in setpoint is given.

Read more...

A reliable water supply: The make or break in building metros across South Africa

VEGA Controls SA

Flow Measurement & Control

South Africa’s urban centres encounter substantial water supply challenges. Maintaining stable water infrastructure is essential for the health, economic vitality and well-being of communities.

Read more...