The launch of the new Neles RotaryGlobe control valve was recently announced by Metso Automation. The company bills it as a major design breakthrough that combines the best features of proven linear and rotary valve technologies in small-bore control valves capable of operating cost-effectively up to ASME 1500 pressure class. The flow characteristics of this new valve are just like those of a globe valve; by definition, the globe-style body design leads to a high pressure-recovery factor. And, as in globe valves, the interchangeable trim selections include low Cv, low noise and anti-cavitation trims to meet a wide range of applications with the same basic valve design. These factors combined with compact size and the low emission characteristics of a rotary valve create a unique design, which offers higher standards of performance in flow-control accuracy and reliability, while reducing lifetime costs and maintenance requirements.

The launch of the new Neles RotaryGlobe control valve was recently announced by Metso Automation. The company bills it as a major design breakthrough that combines the best features of proven linear and rotary valve technologies in small-bore control valves capable of operating cost-effectively up to ASME 1500 pressure class. The flow characteristics of this new valve are just like those of a globe valve; by definition, the globe-style body design leads to a high pressure-recovery factor. And, as in globe valves, the interchangeable trim selections include low Cv, low noise and anti-cavitation trims to meet a wide range of applications with the same basic valve design. These factors combined with compact size and the low emission characteristics of a rotary valve create a unique design, which offers higher standards of performance in flow-control accuracy and reliability, while reducing lifetime costs and maintenance requirements.

Neles RotaryGlobe valves are designed to control a wide range of process liquids, gases and vapours in normal, difficult and even severe service. Applications for the new valve span the petrochemical, chemical, oil and gas, refining, power generation and pulp and paper industries.

Innovative design

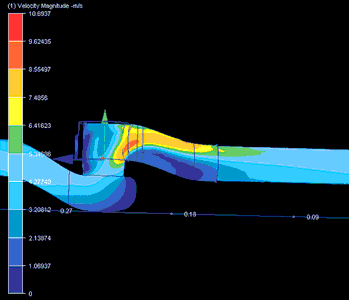

This valve features a compact, lightweight yet robust construction with a choice of trims. Its one-piece, globe-valve style of body minimises potential leak paths and provides enhanced anti-cavitation performance. The rotary motion stem is employed to provide improved control of fugitive emissions. Flow characterisation is achieved by use of the interchangeable trims and intelligent positioners.

The modular design offers interchangeability of parts across the size range, a choice of body materials and a range of linear, equal percentage and balanced trims to accommodate even difficult applications. For example, under high-noise conditions, the low-noise trim can reduce noise by up to 20 dB.

To reduce potential corrosion and erosion problems, the thrust bearing is isolated from the process fluid and incorporates a stem anti-blow-out device.

The valve, available in the size range 1/2"-2", operates in the temperature range -80°C to +425°C and meets the requirements of both ASME and EN standards. It also fulfils the latest safety requirements and environmental standards such as TA-Luft, Clean Air Act and ISO 15848-1.

Field tests

Since the beginning of 2006, a significant number of the new valves, equipped with Neles actuators and ND9000 intelligent valve controllers, have been undergoing extensive tests in customers' processes all over the world. Well over 100 000 field test hours in a range of duties and across a wide range of industries had been completed by the first quarter of 2007.

The new control valve has been engineered for easy maintenance. For example, inline service is provided by the top-entry design. Internal parts, Cv values and flow characteristics are easy to change using interchangeable trim parts. The company's latest Neles ND9000 intelligent valve controller ensures a high standard of control performance. User-friendly software with online diagnostics facilitates predictive maintenance.

| Tel: | +27 31 502 9350 |

| Email: | [email protected] |

| www: | www.valmet.com/flowcontrol/ |

| Articles: | More information and articles about Valmet South Africa, Flow Control |

© Technews Publishing (Pty) Ltd | All Rights Reserved