A popular topic in many organisations is the care that companies are taking of the environment. Well-managed monitoring systems for industrial environments are the name of the game. ISO14000 compliance means companies need proof that they comply with the standards and can substantiate this at audit. The risk of poorly monitored systems comes with huge liabilities with consequential losses. Environmental monitoring is diverse, with many constraints and disciplines requiring measurement, recording and reporting.

Omniflex applies its latest technology to these issues enabling and empowering organisations to take the lead in this area of monitoring by providing the communications, recording and reporting infrastructure to integrate diverse measurement instrumentation into a cohesive solution.

Utilities monitoring? Water quality and usage? Effluent and treatment plants? Wastage, spoilage, loss? SHEQ and ISO reporting systems?

It all boils down to how to better measure and provide the results where you need them and in a form that is easy to use. Data2Desktop can present data to the people that need it from anywhere the organisation operates.

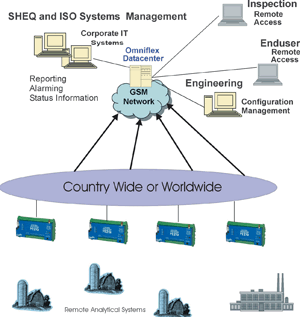

The World Wide Web and GSM networks facilitate the presentation and dissemination of data. This enables distributed operations to collect and consolidate data through the use of GSM-enabled remote terminal units (RTUs), which can interface with remote field units called data access points (DAPs) at a multitude of local or global locations. Dissemination of information uses e-mail or SMS to reach personnel involved in the process.

The Omniflex product offering takes the form of RTUs located in the field and distributed as necessary at areas that required monitoring such as off-site effluent treatment plants. The RTUs can be integrated into the analytical measurement systems of these plants so that the entire organisation can be aware of conditions at remote process plant.

The Teleterm M2 Series RTUs are available in many variants for network flexibility from Ethernet, Conet, Modbus and wireless versions with radio or GSM communications. This provides many solutions for gathering data at the GSM DAPs. Access to data is via the World Wide Web using the Data2Desktop service provided by the Omniflex Data Centre which is located within the GSM cellular communications cloud and accessible via the Internet. This allows many users access to data using an Internet browser and requiring no investment in special software.

Widely distributed company assets can be viewed on a webpage by authorised users from any remote location. Data from the data centre can be acquired into corporate MIS systems through the use of an OPC server or special drivers. These integrate the data into databases like SQL or MYSQL that are widely used in large commercial software solutions. In this way the actual status of measurements from geographically remote locations can be compared against legislated or target levels required. Discrepancies in the monitored system variables can be immediately identified instead of only coming to light during periodic audits. Alarming and notifications to responsible people can be generated automatically. Actual non-conformances can be identified with date and time and not just from historical logged data files.

The implication of this is that the collection of real measurements from remote distributed assets can be automated without reliance on human intervention.

Many organisations rely on manual systems within SHEQ and ISO standards portfolios to manage conformance, with occasional hands-on verification to prove measurements and accuracy. Often these systems are not effective as time-stretched staff struggle to maintain systems while production and throughput take precedence. Measurable benefits quickly accrue to organisations in which this data acquisition is automated,

For more information contact Ian Loudon, OMNIflex, +27 (0)31 207 7466, [email protected], www.omniflex.com

| Tel: | +27 31 207 7466 |

| Email: | [email protected] |

| www: | www.omniflex.com |

| Articles: | More information and articles about Omniflex Remote Monitoring Specialists |

© Technews Publishing (Pty) Ltd | All Rights Reserved