Why consider standardisation?

According to the PLCOpen organisation, standardising the programming interface harmonises the way people design and operate industrial controls. A standard programming interface allows people with different backgrounds and skills to create different elements of a program during different stages of the software lifecycle: specification, design, implementation, testing, installation and maintenance. Yet all pieces adhere to a common structure and work together harmoniously. Decomposition into logical elements, modularisation and modern software techniques result in programs that are structured, have increased re-usability, fewer errors and that are developed more efficiently.

Standardisation facilitates training by allowing users to learn on one model of hardware, but apply common techniques to all compatible hardware. This approach also facilitates maintainability and removes subjectivity from software development making code and is immediately familiar, even if not developed by the reader of that code.

What standards and guidelines are available?

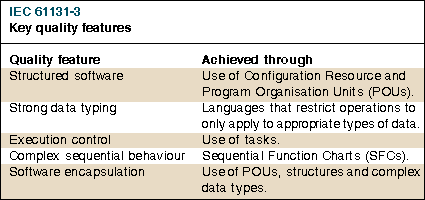

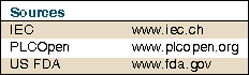

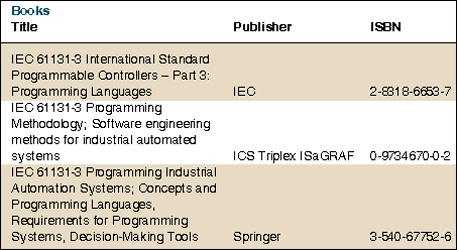

IEC 61131-3

The primary standard available for programmable logic controller (PLC) programming is defined in IEC 61131. This standard has been embraced by many other international standards organisations. For example, the American National Electrical Manufacturers Association (NEMA) standard IA 2.3-2005 is based on IEC 61131-3 as is the British Standard BS EN 61131-3.

There are other bodies that have developed their own industry related standards, but these do not generally go into the same prescriptive depth as IEC 61131 and tend to be more application specific.

US Food and Drug Administration

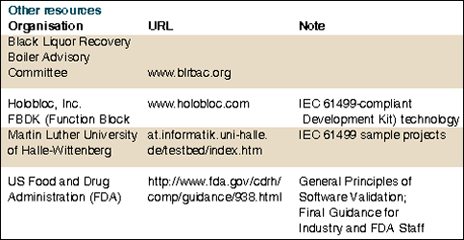

In pharmaceutical manufacturing, systems have to be formally validated before they can be put into production. The US Food and Drug Administration (FDA) has published 'General Principles of Software Validation; Final Guidance for Industry and FDA Staff'. This requires documentation of the software lifecyle, within which a software design specification (SDS) is required. Development procedures and coding guidelines are an important element of the SDS.

A key paragraph in this document reads:

"Firms frequently adopt specific coding guidelines that establish quality policies and procedures related to the software coding process. Source code should be evaluated to verify its compliance with specified coding guidelines. Such guidelines should include coding conventions regarding clarity, style, complexity management, and commenting. Code comments should provide useful and descriptive information for a module, including expected inputs and outputs, variables referenced, expected data types, and operations to be performed. Source code should also be evaluated to verify its compliance with the corresponding detailed design specification. Modules ready for integration and test should have documentation of compliance with coding guidelines and any other applicable quality policies and procedures."

OMAC

Another body involved in automation standards initiatives is OMAC. On 13 December, 1994, Chrysler, Ford, and General Motors published version 1.1 of 'Requirements of Open, Modular Architecture Controllers for Applications in the Automotive Industry'. The document provided guidelines for a common set of APIs for US industry controllers to better address manufacturing needs for the automotive industry. The requirements for the development are defined in the OMAC Requirements Document whose signatories are Chrysler, Ford, and General Motors. This ultimately led to the establishment of the Open Modular Architecture Controls (OMAC) Users Group. One of the purposes of this group is to establish a specific set of APIs to be used by vendors to sell controller products and services to the aerospace and automotive industries. Another activity in OMAC is the Packaging Workgroup. It deals with a common approach to future product development by the packaging machinery builders that will include more electronic controls from the general motion control (GMC) industry.

Although industry-specific in nature, OMAC has also embraced IEC 61131-3 as its programming guideline.

Black Liquor Recovery Boiler Advisory Committee

The Black Liquor Recovery Boiler Advisory Committee (BLRBAC) covers application specific requirements in its document 'Recommended Good Practice - Safe Firing of Black Liquor in Black Liquor Recovery Boilers'.

IEC 61499

IEC 61499 is an evolving standard which defines a generic architecture and presents guidelines for the use of function blocks in distributed industrial-process measurement and control systems (IPMCSs), or more simply distributed control systems (DCSs). This standard presents the architecture in terms of implementable reference models, textual syntax and graphical representations.

IEC 61131

This standard is broken down into:

* IEC 61131-1 Programmable controllers - Part 1: General information.

* IEC 61131-2:2003 Programmable controllers - Part 2: Equipment requirements and tests.

* IEC 61131-3:2003, Programmable controllers - Part 3: Programming languages.

* IEC 61131-4:2004 Programmable controllers - Part 4: User guidelines.

* IEC 61131-5:2000 Programmable controllers - Part 5: Communications.

* IEC 61131-7: Programmable controllers - Part 7: Fuzzy control programming.

* IEC 61131-8:2003 Programmable controllers - Part 8: Guidelines for the application and implementation of programming languages.

The main sections of interest from a PLC programming standards standpoint are IEC 61131-3, 61131-4 and 61131-8.

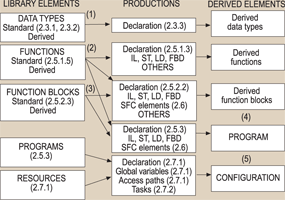

IEC 61131-3 specifies syntax and semantics of programming languages for programmable controllers, 61131-4 is general in nature but does address some safety related matters, while 61131-8 applies to the programming of programmable controller systems using the programming languages defined in IEC 61131-3. It also provides guidelines for the implementation of these languages in programmable controller systems and their programming support environments (PSEs).

One standard, four languages

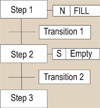

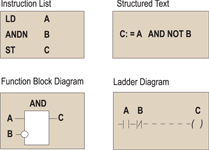

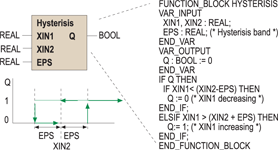

The standard includes the definition of the sequential function chart (SFC) language, used to structure the internal organisation of a program, and four inter-operable programming languages: instruction list (IL), ladder diagram (LD), function block diagram (FBD) and structured text (ST). Via decomposition into logical elements, modularisation and modern software techniques, each program is structured, increasing its re-usability, reducing errors and increasing programming and user efficiency.

PLCOpen

The main user resource for IEC 61131 is PLCOpen which was founded in 1992 and is headquartered in The Netherlands. PLCOpen is a vendor- and product-independent worldwide association whose mission is to be the leading association resolving topics related to control programming and to support the use of international standards in this field.

PLCopen has supporting offices in Canada, Tokyo, Japan and China.

The organisation has extensive online resources, and ongoing projects concerning the development and application of standards for special application areas such as motion control and packaging.

For more information contact Andrew Ashton, Technews, +27 (0)11 886 3640, [email protected], www.instrumentation.co.za

| Tel: | +27 11 543 5800 |

| Email: | [email protected] |

| www: | www.technews.co.za |

| Articles: | More information and articles about Technews Publishing (SA Instrumentation & Control) |

© Technews Publishing (Pty) Ltd | All Rights Reserved