According to National Instruments, the PLC, a dominant tool for industrial engineering, was built for discrete control applications. They have expressed the opinion that as industrial machines and factories grow in complexity, engineers are finding it almost impossible to solve all of their application challenges using PLCs. New programmable automation controller (PAC) hardware systems are an effective add-on solution for existing PLC-based systems because they can easily be integrated with PLCs to create more advanced functionality in industrial machines and improve the efficiency of today's machines.

Improving machine efficiency

Integrated Industrial Systems (I²S) needed to improve on one of its existing PLC-based systems. I²S is a privately owned US OEM that claims to be an industry leader in producing state-of-the-art rolling mill equipment and control systems for the ferrous and nonferrous metals industry worldwide.

I²S has used PLCs for years to automate and control its rolling mills. Recently, it needed to update its rolling mill control system to improve efficiency and quality by modifying its gamma gauging system to more accurately control the metal thickness. The gamma gauging system has been a staple of the I²S product family for many years, but many of the features, both hardware and software, have become outdated. To update the system and improve its machines, I²S required a solution that would offer improved precision of thickness measurement and control.

Step 1: Try to use what exists

To save time and money, I²S first tried to implement the advanced analog measurement and processing within the existing PLCs that automate the rolling mills. Unfortunately, the PLCs did not provide the necessary analog I/O signal resolution and processing power required.

Step 2: If at first you do not succeed.

After realising that the PLCs were not up to the task, I²S turned to PAC technology. The company chose National Instruments' CompactRIO PAC to provide the additional functionality required. National Instruments claim that this PAC is a reconfigurable embedded system that features the ruggedness and reliability of a PLC while providing more advanced I/O and processing than that offered by traditional PLCs. These PAC products are programmable with the company's LabVIEW graphical programming tools, which makes them easy to program and configure.

Step 3: Add advanced I/O

I²S used CompactRIO analog input modules to connect to the gamma-based thickness sensors and to provide the high-speed timing and resolution required. Because each I/O module is connected directly to the FPGA, its engineers used LabVIEW to easily customise the analog I/O rates of the PAC.

CompactRIO has an embedded field-programmable gate array (FPGA) chip and realtime processor that can be programmed with built-in LabVIEW function blocks. The PAC has more than 30 analog and digital I/O modules that contain built-in signal conditioning (anti-aliasing, isolation, ADCs, DACs, and so on), high-speed timing (up to 800 kHz for analog I/O and up to 30 MHz for digital I/O), and high resolution (up to 24-bit ADCs) for connection to industrial sensors and actuators.

Step 4: Add advanced processing

After acquiring the raw analog data from the gamma sensors, the realtime processor of the PAC uses LabVIEW's realtime floating-point function blocks to convert it to an accurate thickness measurement. The software performs deterministic, advanced logarithmic processing (as shown below in equations 1 and 2) on the data to calculate the thickness measurements. With built-in math and analysis functions, programming of this proved to be a very easy task for I2S engineers.

Equation 1: log I = log I0 γ/μ = (γ/μ) log I0

Equation 2: μ = γ log I0/log I = γ log (I0 - I)

The CompactRIO system performs all of the I/O and signal processing in the FPGA and realtime processor and transmits a high-accuracy thickness measurement to the connected PLCs without slowing down the existing PLC control loop rates.

Step 5: Integrate PACs

There are three fundamental methods of connecting PACs to existing PLC architectures:

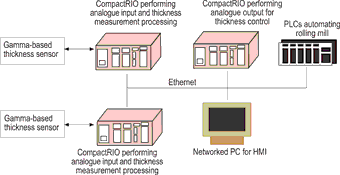

1. Basic analog and digital I/O. This is the most basic way to integrate PACs with PLCs and is how I²S transferred the processed data from the PAC to the PLCs running the rolling mill control loop.

2. Industrial networks and protocols such as DeviceNet, Profibus and CANopen and Ethernet-based protocols such as TCP/IP, UDP, and Modbus TCP/IP. I²S used Ethernet protocols to transfer data between the PACs and to interface the PACs and PLCs to the networked human-machine interface (HMI).

3. OPC connectivity. PACs can also act as OPC (OLE for process control) clients or servers. The OPC standard provides a generic set of routines to help automation systems from different vendors interface easily.

The processed data is transmitted between networked CompactRIO systems over Ethernet in intervals of less than 20 ms. The acquisition, processing, and transmission of the measurements all happen fast enough to inject an accurate thickness measurement into the PLC control loop without decreasing control-loop speed. Using the 10/100 Mb/s Ethernet port of the system, I²S were able to easily connect to networked Allen-Bradley PLCs and the HMI system via a standard TCP/IP protocol. All the instruments within I²S rolling mills are Ethernet-based, which eliminates the need for analog signals to travel long distances in an electrical, noisy environment.

Conclusion

With the advances in machine technology and the need to increase automation efficiency, PLCs are often not able to do everything alone. PAC technology complements PLCs and adds the high-performance I/O and processing that traditional PLCs cannot provide. And with the variety of methods to connect PACs into existing PLC architectures, engineers have an easy way to boost their PLC-based automation systems.

For more information contact National Instruments South Africa, +27 (0)800 203 199, [email protected], www.ni.com/blackfin

© Technews Publishing (Pty) Ltd | All Rights Reserved