Now available to South African manufacturers is a PC co-processor that turns a PC into a programmable local controller (PLC) simply by slotting it into the motherboard. This embedded realtime controller meets the need for openness and cost savings while providing a reliable, robust operating system that will not crash - even if the PC does.

At the heart of Schneider Electric's Telemecanique offer, Unity is the new generation software and hardware automation platform that makes this possible. Its ingenuity reduces development times, puts productivity first and its processor flexibility offers greater execution performance.

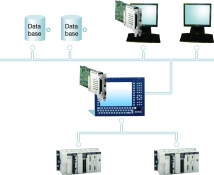

When used with a Magelis industrial PC, Modicon Atrium slot PLCs offer the functionality of a PC integrating a programmable logic controller and supervisory software. This type of configuration is particularly suitable for installations requiring a high level of interaction between automation functions and human machine interface (HMI) applications. The software gateway enables Modicon Atrium PLCs to communicate using Modbus or Uni-TE Ethernet TCP/IP via an integrated Ethernet port on the industrial PC.

Transparent Ready is the successful combination of Ethernet and industrial communication technologies. With the benefit of these technologies, Modicon Atrium offers the best of Ethernet whatever the task, be it e-mail transmission, direct database access, equipment synchronisation, I/O distribution, and more.

Says Schneider Electric's automation product manager, Linda Eales: "manufacturers can now choose the best components available on the market for their machines. Unity affords an inherently simple, flexible and open offer ensuring each design is both efficient and unique.

"Modicon Atrium is plug-and-play. It integrates easily into the PCI bus on the PC and is Windows-compatible for ease of use. Modicon Atrium's centralised diagnostic data is accessible to authorised personnel, from any location in the architecture, via the Ethernet TCP/IP network.

"In order to enable standalone operation in the event of a PC power outage, a standalone c 24 V TSX PSI 2010 power supply can be connected to a PCI or ISA bus slot to ensure continuity of service for the automation part of the system - only functions managed by the PC are disabled.

"Maintenance is simplified - all that is needed is a screwdriver to hot swap a faulty I/O module. Modicon Atrium detects, identifies and reconfigures the new module. This means the added benefit of ensuring the availability of your production line. You can avoid production downtime and prioritise long-term durability, flexibility and connectivity".

Manufacturers can define their communication medium - Modicon Atrium connects to any I/O system, whether local or distributed: CANopen, Ethernet TCP/IP, AS-Interface, BusX, WorldFIP, Fipio, Modbus, SERCOS, Profibus, INTERBUS. Totally compatible with the OPC standard, Modicon Atrium communicates easily with the software offers of your choice.

Continues Eales: "Manufacturers can make the most of their existing knowledge. With Unity Pro programming software, Modicon Atrium application memory is more flexible than ever before. All five IEC 61131-2 languages are available, without compromising performance. It has never been so easy to re-use expertise, thanks to the handling of DFBs (derived function blocks) and structured variables.

"Tools can be used collaboratively - Unity Pro is the common programming tool for Modicon Premium, Atrium and Quantum PLCs and it adopts market standards such as XML, Visual Basic and COM/DCOM.

"To control your machine remotely, simply connect the Modicon Atrium to the universal Ethernet TCP/IP network and perform the necessary operations from any location.

"Modicon Atrium's variable geometry design means that it can be adapted for use with the majority of PCs, regardless of the distance between two PCI slots. It is compatible with all modules in the Modicon Premium range (motion, communication) as well as the software, remote I/O and safety components for machines of Telemecanique offer.

"As is true for all our Telemecanique PLCs, Modicon Atrium complies with international standards including CE marking, IEC/EN 61131-2, UL, CSA, CSA Hazardous Location Class I Div 2, as well as marine standards."

When used with Schneider's FactoryCast HMI module, Modicon Atrium offers a whole range of services, including:

* Automatic data storage: by feeding data directly into your remote relational databases (Microsoft SQL server, Oracle, MySQL), Modicon Atrium offers a cost-effective solution ensuring total traceability. Data can be shared with SCADA systems and direct links established with management systems manufacturing execution system (MES), and enterprise resource planning (ERP).

* Managing data by e-mail: wherever you are, you can receive e-mail or SMS messages directly on your laptop, PDA or mobile phone, relating to any process event or alarm you have configured.

* Updating the HMI web interface: through a simple subscription, your animations can be refreshed with no web client polling and only when the variables change their state. This reduces the network load, irrespective of the number of clients connected.

For more information contact Linda Eales, Schneider Electric South Africa, +27 (0) 11 254 6400, [email protected]

| Tel: | +27 11 254 6400 |

| Email: | [email protected] |

| www: | www.se.com/za/en/ |

| Articles: | More information and articles about Schneider Electric South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved