Evolving trends in the manufacturing industry are causing a rethink of priorities with regard to measuring the effectiveness of production processes. In today’s customer-driven economy, responsiveness is the order of the day if business levels are to be increased or even maintained.

Fortunately, achieving ambitious business goals in what is arguably one of the most competitive industries in the world is no longer relegated to the realm of wishful thinking.

Technology trends in manufacturing

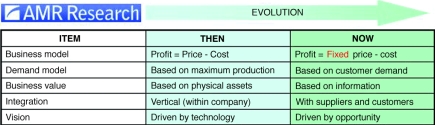

* In the past, manufacturers set their prices based on cost of production plus a healthy profit (see Figure 1). Today the market determines the price of products and profit can only be increased by driving down the cost of production.

* Traditionally, manufacturers maximised the use of assets and produced to stock. Today, the customer determines what goods are produced and when that will happen.

* Business value used to be determined by physical assets, but currently, information is the basis of much of the value of a business (available to promise, lower production costs, supply chain visibility).

* Integration focus was vertical between plant floor and the business systems whereas now the focus is on an integrated supply chain.

* The business vision was always driven by the dependence on technology but this has changed to be driven by opportunities that are supported by technology.

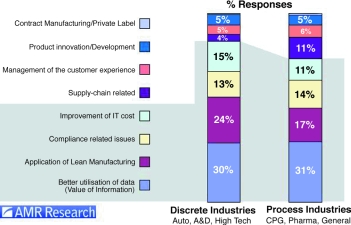

According to AMR's survey, the top business issues driving IT investments in manufacturing today are as shown in Figure 2, which graphically illustrates that the vast majority of concerns revolve around issues that are highly dependent on quality information. Even lean manufacturing is entirely dependent on information because it is intended to satisfy the needs of customers (whether internal or external) - which cannot be done without feedback of some sort (for example CRM). Lean manufacturing must also anticipate what customers will need, when they will need it and how much of it they will need. And it all has to be done by using the minimum of materials, equipment, space, labour and time. These are all parameters that will determine the required production effort and processes that will be deployed and they are all based on the aggregation of information from a wide variety of sources.

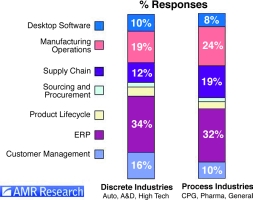

Modern ERP systems have gone a long way to address supply chain integration and as such unleashed huge value. The focus is now moving back to manufacturing operations as the next logical strategic investment. Figure 3 shows that, although ERP is still a highly strategic software investment, manufacturing operations is the second largest and it is no wonder that this is so. Manufacturing operations are the core wealth creating processes of these companies and without them, there would be no company and certainly no wealth to count.

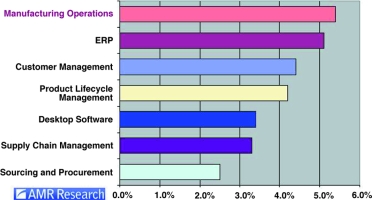

The most leverage a company has on improving its business status has little to do with enhancing peripheral and supportive processes but rather more to do with focusing on improving its wealth creation potential. This is what is happening as shown in Figure 4, which illustrates a major investment in improving manufacturing operations.

While wish lists have made several processes important, the improvements are not all there, let alone performance analysis on a multisite basis. In fact, production management's visibility into KPIs was judged as the major critical factor in improving manufacturing operations. This was closely followed by the necessity to get time-series data from the plant floor and the ability to comply with regulatory requirements. Then came:

* The aggregation of data from multiple plant sources.

* Enterprise visibility of production financial performance.

* Multisite performance analysis.

* Multisite aggregation of data from production assets.

* The centralised repository of multisite data.

Wonderware provides technology, which supports solutions helping to address these issues. At the centre of this is the ArchestrA infrastructure, which has seen US $100 million invested in its development over the last three years and wide acceptance in the manufacturing and mining industries. ArchestrA is the platform for Wonderware's 'production and performance management' (PPM) solutions - but what, exactly is meant by PPM?

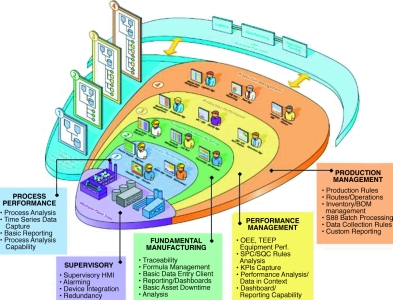

Production and performance management

* Production management is defined as "the transformation of business objectives into operational commands". It is the ability to identify and quickly implement operational changes in plant production when required by changes in business objectives and market demand.

* Performance management is defined as "understanding the impact operations have on the company's business". It is the ability to monitor and understand how operational processes are impacting the company's business goals and bottom line.

While success in both of these management activities is necessary for maximum efficiency, many manufacturers do not have the technology and tools they need to succeed in these areas. Wonderware offers production and performance management software solutions that integrate and accelerate these management processes, and close the gap between operational processes and business strategies.

Wonderware provides all the software and partners needed to support the capabilities required for operational performance. This includes device integration, supervision/control, data collection, tracking, process analysis, KPI, realtime production monitoring/reporting, MES, OEE, SPC, batch management, WIP execution and other functions - even ERP integration. ArchestrA's flexible, scalable technology integrates existing systems to reduce total time to value, total cost of ownership and other operational improvements. These software solutions can tie together existing plant, IT and business systems and enable solutions to evolve at the company's own business pace.

The proof of the pudding is in the eating. Wonderware grew by 12% in 2005 (while standard growth of the industry was only 5%) due of the acceptance of ArchestrA technology and this growth is anticipated to rise to 17% in 2006. Leading manufacturers at last have an infrastructure they can build onto without invalidating past investments and that will help them measure and monitor the all-important aspects of production and performance management.

© Technews Publishing (Pty) Ltd | All Rights Reserved