Implementing a modern industrial application can present a challenging and sometimes daunting mix of requirements.

For example, it is well understood that a typical control system

must interface with signals from simple sensors and actuators, yet for many modern applications this is merely the starting point.

Advanced control features, network connectivity, device interoperability, and enterprise data integration are all capabilities increasingly demanded in a modern industrial application. These modern requirements extend far beyond the traditional discrete-logic-based control of input/output (I/O) signals handled by a programmable logic controller (PLC). Most PLCs are programmed using ladder logic, which has its origins in the wiring diagrams used to describe the layout and connections of discrete physical relays and timers in a control system.

Applications that diverge from or expand beyond this model become increasingly hard to program in ladder logic. For example, mathematically complex applications such as proportional-integral-derivative (PID) loops used for temperature control involve floating-point arithmetic. To perform these calculations, PLCs must often be enhanced with separate - and separately programmed - hardware cards.

Making a PLC more like a PC

Using a PLC to meet modern application requirements for network connectivity, device interoperability, and enterprise data integration presents other challenges. These types of tasks are usually more suited to the capabilities of a computer (PC). To provide these capabilities in a PLC-based application, additional processors, network gateways or converters, 'middleware' software running on a separate PC, and special software for enterprise systems must often be integrated into the system.

Making a PC more like a PLC

On the other hand, a PC packaged for industrial environments can provide many of the capabilities sought in modern applications, particularly those needed for networking and data communication. Similar to augmenting a PLC to accomplish PC-like tasks, however, an industrial PC that needs to perform PLC-like tasks, such as machine or process control, also requires expansion. For example, a PC may be using an operating system that is not optimised for high-performance and deterministic industrial applications. Additional I/O expansion cards or special extensions may need to be integrated into the PC's operating system to provide the high-performance, deterministic or near-deterministic operation.

Introducing the PAC

Automation manufacturers have responded to the modern industrial application's increased scope of requirements with industrial control devices that blend the advantages of PLC-style deterministic machine or process control with the flexible configuration and enterprise integration strengths of PC-based systems. Such a device has been termed a programmable automation controller, or PAC.

While the idea of combining PLC and PC-based technologies for industrial control has been attempted previously, it has usually only been done through the 'add-on' type of approach described earlier, where additional middleware, processors, or both are used in conjunction with one or more PLCs. A PAC, however, has the broader capabilities needed built into its design. For example, to perform advanced functions like counting, latching, PID loop control, and data acquisition and delivery, a typical PLC-based control system requires additional, and often expensive, processing hardware. A PAC has these capabilities built in.

A PAC is notable for its modular design and construction, as well as the use of open architectures to provide expandability and interconnection with other devices and business systems. In particular, PACs are marked both by efficient processing and I/O scanning, and by the variety of ways in which they can integrate with enterprise business systems.

Characteristics of a PAC

Most agree that industrial analyst ARC Advisory Group originated the term 'PAC'. ARC coined the term for two reasons: to help automation hardware users better define their application needs, and to give automation hardware vendors a term to more clearly communicate the capabilities of their products. According to ARC, a programmable automation controller must fulfil the following requirements:

* Operate using a single platform in multiple domains, including logic, motion, drives, and process control.

* Employ a single development platform using common tagging and a single database for development tasks across a range of disciplines.

* Tightly integrate controller hardware and software.

* Be programmable using software tools that can design control programs to support a process that 'flows' across several machines or units.

* Operate on open, modular architectures that mirror industry applications, from machine layouts in factories to unit operation in process plants.

* Employ de-facto standards for network interfaces, languages, and protocols, allowing data exchange as part of networked multivendor systems.

* Provide efficient processing and I/O scanning.

Development and functional benefits

The characteristics that define a PAC also describe well the key advantages of deploying a PAC in an industrial application. These advantages include being able to independently meet complex requirements that PLCs require extra components to do, and improved control system performance due to tightly integrated hardware and software.

The integrated hardware and software is also an advantage when programming: the integrated development environment (IDE) used to program a PAC includes a single tagname database shared by all development tools. PACs use one software package to address existing and future automation needs, instead of using multiple software packages and utilities from various vendors.

Another PAC benefit is how easily control systems can be upgraded. Modular processor hardware can be replaced with no need to rip out existing sensor and actuator wiring. Due to its compact size, a PAC also conserves valuable cabinet space.

Acronyms used in this article:

* DAQ: data acquisition.

* ERP: enterprise resource planning.

* HMI: human-machine interface.

* I/O: input/output.

* IDE: integrated development environment.

* IP: Internet protocol.

* OEE: operational equipment effectiveness.

* OEM: original equipment manufacturer.

* OPC: OLE for process control.

* PAC: programmable automation controller.

* PC: personal computer.

* PID: proportional-integral-derivative.

* PLC: programmable logic controller.

* PPP: point-to-point protocol.

* PSTN: public switched telephone network.

* RTU: remote terminal unit.

* Scada: supervisory control and data acquisition.

* SCM: supply chain management.

* SNMP: simple network management protocol.

* SQL: structured query language.

* TCO: total cost of ownership.

* TCP: transmission control protocol.

With their modern networking and communication capabilities, PACs make production information available in or near realtime. This in turn makes the data collected more accurate and timely, and thus more valuable for business use.

Financial benefits

PACs can offer multiple financial advantages. The overall cost of the control system is lowered because hardware is less expensive, and less development and integration time is needed. Purchasing a PAC is often more affordable than augmenting a PLC to have similar capabilities.

There is also an increased return on assets, reduced lifecycle costs, and lower total cost of ownership (TCO) due to extending an automation system's range of applications (also known as its domain expertise).

Finally, cash flow is improved: the ability to add I/O as separate modules means that just the minimum number of modules needed for initial development can be used during design, and the remaining modules added toward the end of the project.

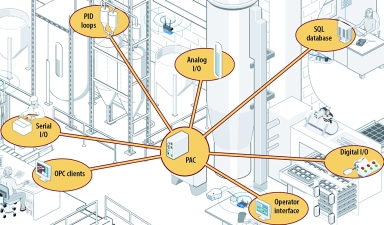

Let us look more closely at how a PAC is applied to a modern industrial application, using the factory application illustrated in Figure 1.

Single platform operating in multiple domains

The single PAC shown in Figure 1 is operating in multiple domains to monitor and manage a production line, a chemical process, a test bench, and shipping activities. To do so, the PAC must simultaneously manage analog values such as temperatures and pressures; digital on/off states for valves, switches, and indicators; and serial data from inventory tracking and test equipment. At the same time, the PAC is exchanging data with an OLE for process control (OPC) server, an operator interface, and a SQL (Structured Query Language) database. Simultaneously handling these tasks without need for additional processors, gateways, or middleware is a hallmark of a PAC.

Support for standard communication protocols

In the factory example in Figure 1, the PAC, operator and office workstations, testing equipment, production line and process sensors and actuators, and barcode reader are connected to a standard 10/100 Mbps Ethernet network installed throughout the facility. In some instances, devices without built-in Ethernet connectivity, such as temperature sensors, are connected to I/O modules on an intermediate Ethernet-enabled I/O unit, which in turn communicates with the PAC.

Using this Ethernet network, the PAC communicates with remote racks of I/O modules to read/write analog, digital, and serial signals. The network also links the PAC with an OPC server, an operator interface, and a SQL database. A wireless segment is part of the network, so the PAC can also communicate with mobile assets like the forklift and temporary operator workstation.

The PAC can control, monitor, and exchange data with this wide variety of devices and systems because it uses the same standard network technologies and protocols that they use. This example includes wired and wireless Ethernet networks, Internet Protocol (IP) network transport, OPC, and SQL. In another control situation, common application-level protocols such as Modbus, SNMP (Simple Network Management Protocol), and PPP (point-to-point protocol) over a modem could be required. The PAC has the ability to meet these diverse communication requirements.

Exchange data with enterprise systems

In the factory example, the PAC exchanges manufacturing, production, and inventory data with an enterprise SQL database. This database in turn shares data with several key business systems, including an enterprise resource planning (ERP) system, operational equipment effectiveness (OEE) system, and supply chain management (SCM) system. Because data from the factory floor is constantly and automatically updated by the PAC, timely and valuable information is continually available for all business systems.

RTUs, data acquisition, and PACs

A remote terminal unit (RTU) is a controller-like device that is installed at a remote location to collect sensor and other data. Popular for decades, RTUs are typically used as part of a supervisory control and data acquisition (scada) network, where an RTU sends data to a scada master. The RTU also receives information from the scada master to operate field devices at the remote location.

Comparing RTUs and PLCs

RTUs are primarily deployed in distant geographic areas to monitor, acquire, and control remotely-dispersed assets such as pipelines, wellheads, lift stations, or telecommunications facilities. Traditional PLCs do not natively possess the communication capabilities needed for use in these types of applications. Also, PLCs typically do not offer the ruggedness to withstand harsh environmental conditions, nor the flexible I/O configuration required in most RTU applications. In the absence of these capabilities, RTUs were developed specifically with a focus on communication capabilities, suitability for harsh environments, and flexible I/O configuration.

However, legacy RTU communication capabilities are usually outdated, as they were developed in a time of private radio or leased-line networks. Today's open, IP-based wired and wireless local- and wide area networks are more flexible and often less expensive. Because of this, retrofitting an existing RTU or implementing new applications using outdated RTU technology does not make good business or technical sense.

PACs, in contrast, provide superior communication capabilities, versatile I/O options, broad temperature and shock specifications, and use today's leading communication standards. These features make PACs a well-suited alternative to legacy RTUs in the field, especially when older, proprietary networks are retired due to increasing maintenance costs or obsolescence.

PC-based data acquisition

A data acquisition (DAQ) system is a PC-based device that provides fast signal acquisition, basic signal conditioning, data storage capabilities, and limited networking. The majority of DAQ systems are PC-based, limiting their use in challenging physical environments or remote locations. Most DAQ systems thus find their home in the comfort of a laboratory rather than in field locations.

PACs offer versatile and flexible signal sensing, conditioning, and multiplexing. With a PAC's powerful processors and large amounts of global memory, acquired raw data can be aggregated, collated, or otherwise processed (for example, converting raw data into engineering units) before being sent to a database or other application. Alternately, the data could be archived locally. Because a PAC is not a PC and is not hindered by a PC's high cost of ownership, it can be deployed in field applications with confidence.

Choosing a PAC

A variety of industrial automation vendors now offer PAC or PAC-like products. In some cases, the product is more PLC-like, while in other cases the offering is more like an industrial PC. As described earlier, PACs integrate capabilities from both of these devices, so a device that emphasises PLC or PC capabilities may or may not fit a specific applications requirements.

Check vendor experience

As with any product, some vendors have been in the game longer than others. While many vendors have recently introduced their new PAC or PAC-like offerings, a select few companies have demonstrated a successful track record of providing PAC functionality several years before the term itself entered the mainstream. Opto 22 is one of these companies.

PACs and Opto 22

In 1990, 11 years before ARC Advisory Group coined the term PAC, Opto 22 was first to market with a PAC-type hardware device in the form of its computer-based mistic controller.

Current Opto 22 SNAP PAC systems build on more than 15 years of experience and thousands of successful mistic and other PAC installations all over the world in applications involving semiconductor processing, material handling, water and wastewater treatment, pipeline monitoring, and more. Today, what sets Opto 22 PAC systems apart from those of other vendors is this wealth of experience, coupled with ease-of-use, versatility, scalability, and reliability.

A PAC provides in a single compact controller the advanced control features, network connectivity, device interoperability, and enterprise data integration capabilities found in PLC- or PC-based automation controllers. With these features, the PAC has become an integral part of meeting the new and diverse requirements demanded in a modern industrial automation.

For more information contact Mike Harrison, Opto Controls, 011 792 5232, [email protected], www.opto.co.za

| Tel: | +27 11 792 3560 |

| Email: | [email protected] |

| www: | www.opto.co.za |

| Articles: | More information and articles about Opto Controls |

© Technews Publishing (Pty) Ltd | All Rights Reserved