During late October 2005, Yokogawa Electric Corporation celebrated 90 years of business. It took the opportunity to show the international press other perspectives of the company that has traditionally relied on ‘the products speaking for themselves’ rather than on sophisticated PR and advertising. And like me, you thought that Yokogawa was just an industrial automation company? Think again!

Yokogawa currently spends 7,5% of its turnover on research and development (R&D). According to the Institute of Electrical Engineers (USA, October 2005), this is significantly higher than most other technology companies. SA Instrumentation & Control was given a 'sneak preview' of some of the emerging technologies that Yokogawa is developing, many of which may have little to do with industrial control. At least on the surface they may have little relevance. Scratch a little deeper, and some really exciting concepts start to emerge.

40 Gbps networking

Existing networking technology is severely speed-constrained by needing to switch optical fibre traffic with semiconductor-based technology. The conversion between the semiconductors and the photons carried in the fibre (and back again at the other side) introduce significant delays in data throughput (latency). The conversion process is also inefficient, consuming relatively large amounts of power.

Optical packet switching (OPS) technology eliminates this data bottleneck. Light is converted from one wavelength to another without passing through a semiconductor. Yokogawa used the birthday celebration to demonstrate a working example of its own OPS switch operating at 2 ns, fully functional with data rates of 40 Gbps (gigabits per second).

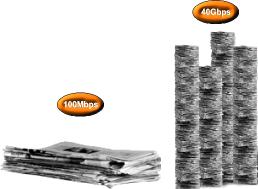

Figure 1 puts this staggering speed into perspective. The company estimates that data contained in eight year's worth of newspapers can be transmitted across the link in one second. A 100 Mbps link could only transmit the data contained in eight day's worth of newspapers.

Most commercial/office networks still operate at either 100 Mbps or 1 Gbps. The industrial control environment has tended to take a rather conservative approach with many networks operating at significantly slower speeds. In all fairness, they often do not need to run any faster.

I would typically have expected this sort of emerging technology to be driven by traditional networking manufacturers (eg, Cisco, Nortel, HP, etc). Regarding the applications it intends to employ the new technology in, quite understandably, Yokogawa chose to not play a completely open deck of cards with the press. However, it does not take a lot of imagination to see numerous opportunities for these speeds in a control environment. For starters, these high data throughput rates could revolutionise emergency shutdown and high-speed motion control systems.

Field wireless networks

Yokogawa would not commit to an expected launch date for its new field wireless networking systems. However, there was a fair amount of speculation that it could be within the next 18 months. Judging by the interest shown in the practical demonstrations, reliable and low-cost wireless networks have tremendous appeal.

Yokogawa's prototype field transmitters are powered by two AA batteries (with a battery life of up to two years). The transmitters are physically not much bigger than the batteries, and comply with the IEEE802.15.4 and Zigbee standards for low power, low bit-rate communications on the physical layer and medium access control layer. The product can support up to 60 000 points on a single network with multihop functions for wide area coverage. In keeping with Yokogawa's strategy, the devices are fully Foundation Fieldbus compliant.

Being able to verify the functionality of all devices via wireless, rather than having to physically connect to them, would be any field-worker's dream. Not to mention the potential savings in long-distance cabling.

The generally poor implementation of 802.11b and g technologies in both commercial and home environments, combined with the technologies having been allocated the same unlicensed frequency band as microwave ovens and other 'rubbish', has given wireless networking a rather shoddy reputation for performance and reliability. It will be interesting to see if all will be forgiven as 802.15.4 is rolled in industrial applications.

Aircraft cockpit displays

Yokogawa and Thales Avionics (Europe's largest avionics manufacturer) have collaborated to produce a liquid crystal cockpit display system that will be installed in the new Airbus A380 that is due to go into service in 2006. Yokogawa demonstrated the panels using 'simulated sunshine'. When compared with standard commercial LCD displays, these panels maintain remarkably good readability even in direct sunlight. They do this by having a very low reflection of incidental light (back to the user). They also maintain a high luminance and provide a high contrast across a wide viewing angle (so that the co-pilot and pilot can read the other's display).

The displays use a multiredundant system architecture with multiple smart display units. They can operate across a wide temperature range, and demonstrate a high resistance to vibration and shock (6 G, 11 ms). They must also be able to withstand sudden barometric pressure changes (in case of explosive decompression). Does this environment sound familiar to you? It sounds rather like a normal, industrial installation.

The Yokogawa spokesperson would not reveal the selling price of the displays. However, I would hazard a guess that most plant operators will have to wait for the price to drop (rather a lot) before they get to play Hearts or Solitaire on one of these.

Gene diagnostic-based personalised medicine

Depending on our genetic makeup, we all respond differently to different drug therapies. Yokogawa is developing a system that will be used to predict the manner in which a patient will respond to the administration of a specific medication (both in its efficacy and the unwanted side-effects). Research has shown that some drugs developed for the general population can be effective on only 60% of patients. Anti-cancer drugs may vary up to a hundredfold for different patients.

Using supersensitive fluorescence measurement technology for confocal scanners, Yokogawa has developed a reader to measure DNA chips (biochips). The equipment enables non-skilled operators to process a blood sample from the patient and obtain a DNA match in a relatively short timeframe.

Instead of the physician taking a wild guess, and hoping to hell that the patient falls in the 'norms of the Bell curve', the results of the DNA scan enable the dosage to be specifically tailored for the patient's needs.

Imagine being able to accurately (and perhaps more significantly, cheaply) predict how each batch of raw material is going to react as it is applied to a specific manufacturing process... you get the picture?

Cerebral aneurysm detection system

Brain disease (that often results in a stroke) is one of the three major diseases in Japan, the primary cause being cerebral aneurysms ie, a ruptured blood vessel that bleeds into the brain cavity. It is estimated that about 5% of adults are unaware of having un-ruptured cerebral aneurysms ie, a stroke waiting to happen.

Although three-dimensional magnetic resonance angiography (3D-MRA) is generally used in screening for cerebral aneurysms, the detection of cerebral aneurysms requires considerable skill and experience due to the complexity of cerebrovascular networks. Yokogawa, in collaborative with Chiba Rousai Hospital (Japan), developed a system for 'automatically' detecting cerebral aneurysms applying 3D-MRA data and Yokogawa's computer aided diagnostics (CAD) system.

Imagine being able to automatically (and reliably) predict the pending failure of a pipeline, rather than using the current expensive and time-consuming inspection techniques...

Seven nines reliability

In all of this, I have not mentioned much about the Yokogawa technology with which we are more familiar... the industrial automation and control systems and T&M equipment. The company has a consolidated annual turnover that equates to approximately R21 billion (371,9 billion Yen in 2003). It employs more than 18 300 personnel and has operations in 28 countries.

In June this year, Yokogawa celebrated 30 years since its launch of the first ever distributed control system (DCS). It is now able to claim a measurable reliability factor of 99 999 995,3% on the latest version of its DCS systems, the Centum CS 3000.

I wonder what boundaries of technology we did not know about that Yokogawa was pushing 30 years ago?

And what boundaries of technology was Dr Yokogawa pushing when he started a small electric meter manufacturing company in Japan in 1915?

I wonder what boundaries will Yokogawa be pushing 90 years in the future?

For more information contact Yokogawa, 011 831 6367, [email protected]

© Technews Publishing (Pty) Ltd | All Rights Reserved