A steam-conditioning valve is used for the simultaneous reduction of steam pressure and temperature to the level required for a given application. Frequently, these applications deal with high inlet pressures and temperatures and require significant reductions of both properties. They are, therefore, best manufactured in a forged and fabricated body that can better withstand steam loads at elevated pressures and temperatures. Forged materials permit higher design stresses, improved grain structure, and an inherent material integrity over cast valve bodies. The forged construction also allows the manufacturer to provide up to Class 4550, as well as intermediate and special class ratings, with greater ease versus cast valve bodies.

Due to frequent extreme changes in steam properties as a result of the temperature and pressure reduction, the forged and fabricated valve body design allows for the addition of an expanded outlet to control outlet steam velocity at the lower pressure. Similarly, with reduced outlet pressure, the forged and fabricated design allows the manufacturer to provide different pressure class ratings for the inlet and outlet connections to more closely match the adjacent piping.

Other advantages of combining the pressure reduction and desuperheater function in the same valve versus two separate devices include:

* Improved spraywater mixing due to the optimum utilisation of the turbulent expansion zone downstream of the pressure reduction elements.

* Improved rangeability.

* Increased noise abatement due, in part, to the additional attenuation of noise as a result of the spraywater injection.

* In some designs, improved response time due to an integrated feedforward capability.

* Ease of installing and servicing only one device.

* Several available steam conditioning valve designs meet various applications.

Typical examples of these follow.

Steam conditioning valve designs

Feedforward design

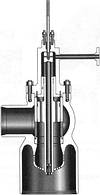

The feedforward steam conditioning valve design (Figure 1) offers all the traditional benefits of the combined valve and features an ability to provide an intrinsic form of feedforward control.

Positioning of the valve plug within the cage controls steam pressure and flow. A signal from the pressure control loop to the valve actuator positions the dynamically balanced valve plug to increase or decrease the amount of flow area. The control cage includes an array of orifices that provide the required flow characteristic. As the plug is lifted from the seat, steam passes through the control cage and down through the seat ring. The valve plug is equipped with a hollow tube both above and below the main plug body. This arrangement connects the valve outlet area (after the seat orifice), with the upper spraywater supply chamber to allow the flow of cooling water.

The upper portion of the water tube is provided with an arrangement of calibrated orifices to allow spraywater to enter and flow down toward the valve outlet. The water tube extends down below the seating surface on the valve plug and is positioned near the flow vena contracta below the main valve seat orifice. The water is injected at a point of high velocity and turbulence, and distributed quickly and evenly throughout the flow stream. Thus, when pressure is recovered downstream of the valve, the water will be almost instantaneously evaporated, providing the required attemperation.

The valve body is provided with a steam seating surface and a water sealing surface. The steam set provides for positive shut-off (Class IV only) of steam flow. It consists of a replaceable seat ring and a hardened valve plug. Piston rings on the valve plug reduce leakage between the guide surfaces. The water seal provides for sealing of the water and includes a seal bushing to prevent leakage. These two control points are designed so that as the valve plug is lifted to permit flow of steam, a proportional amount of water flow is allowed. This provides an instantaneous increase in water flow as steam demand increases, affording more precise control of pressure and temperature over a wide range of steam flows. This feedforward control is coarse control. An external water control valve is required which, operating on a signal from a downstream temperature sensor, will provide the required fine-tuning control.

Due to the design of the plug used in this style valve, there are certain application restrictions in its use. These restrictions deal primarily with the plug's hollow centre and its capacity to pass the required amount of water, as well as the plug's single discharge orifice and its ability to pass enough water and effectively inject the water over the entire steam flow. This style valve is generally supplied as an angle valve, but it can also be supplied as a Y pattern for straight-through installations. In such cases, the application limitations are more restrictive due to spraywater injection into a steam flow that is still changing direction.

Typically this integral feed-forward design is used for process steam reduction stations from the main steam header to the individual process area requirements. It can also be used for other applications where there are small to moderate water addition requirements and small to moderate pressure reduction requirements.

Manifold design

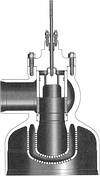

The manifold steam conditioning valve design (Figure 2) offers all the benefits of the combined valve but features its ability to provide multipoint water injection with an externally mounted manifold around the valve outlet. With this manifold, large quantities of water can be injected with homogenous distribution throughout the steam outlet flow.

Similarly, positioning of the valve plug within the control cage controls steam pressure and flow. A signal from the pressure control loop to the valve plug within the control cage to increase or decrease the amount of free flow area. The control cage has an array of calibrated orifices to provide the control characteristic specified. As the plug is lifted from the seat, steam passes into the centre of the control cage and out through the seat ring. The outlet section of the valve is equipped with a combination cooler section/silencer. As the steam leaves the seat ring, it enters a diffuser designed to further decrease steam pressure energy in a controlled-velocity expansion.

Flow is directed radially through the multiple-orifice diffuser, exiting into the enlarged outlet pipe section. This section has been sized to accommodate the large change in specific volume associated with the pressure drop and to keep steam velocities within limits that minimise noise and vibration.

The outlet section is outfitted with a water supply manifold. The manifold (multiple manifolds are also possible) provides cooling water flow to a number of individual spray nozzles installed in the outlet section. The result is a fine spray mist injected radially into the high turbulence of the steam flow.

The combination of large surface area contact of the water and steam coupled with high turbulence make for efficient mixing and rapid vaporisation. Even though there is no intrinsic feed-forward in this valve design, it is possible to obtain feedforward with external control devices. In either case, an external water control valve is required which, operating on a signal from a downstream temperature sensor, will provide the required fine-tuning for temperature control.

The seat provides for positive shutoff of steam flow. It consists of a replaceable seat ring and a hardened valve plug. Piston rings on the valve plug reduce leakage between the guide surfaces.

Due to the rugged design of this valve, there are few limitations to its usage. It is available for high pressure applications, high-pressure reductions, very high water addition both in volume and mass percentage of water to steam, multiple noise reducing diffusers for large pressure drops, very large outlets, and for Class V shutoff. This design is standard as an angle valve, but can be supplied in a Y pattern for straight-through installations, and when desired it can be manufactured in a Z pattern for offset installations.

Typically this valve is used in power (utility, cogeneration, and industrial) plant applications around the turbine for start-up, bypass, condenser-dump, vent, and export steam. It can also be used for other applications where there are moderate to very large water addition and pressure reduction requirements.

Pressure-reduction-only design

The pressure-reduction-only valve design (Figure 3), unlike the combined units, is only used for pressure reduction. The special feature for this style valve is that it is a forged and fabricated body, which is a cost-effective solution for high-end pressure classes and for incorporating noise attenuation diffusers.

Steam pressure and flow are controlled by the positioning of the valve plug within the control cage. A signal from the pressure control loop to the valve actuator positions the valve plug inside the cage to increase or decrease the amount of flow area. The control cage has an array of orifices that provide the required flow characteristic. As the plug is lifted from the seat, steam passes through the cage and down through the seat ring.

The seat provides for positive shutoff of steam flow. It consists of a replaceable seat ring and a hardened valve plug. Piston rings on the valve plug reduce leakage between the guide surfaces.

Due to the rugged forged design, there are few limitations to its usage. As previously mentioned, its greatest cost effectiveness is when it is in the Class 900 pressure range or greater and when the steam temperature requires a chrome molly, stainless steel or other special material body. It is also cost effective when very large outlets are required to match pipe sizes. This style valve also allows for multiple noise reduction diffusers for large noise reductions and is also available with Class V shutoff. It is standard as an angle valve, but can be supplied as a Y pattern for straight-through installations, and when desired it can be manufactured in a Z pattern for offset installations. Typically this valve is used in power (utility, cogeneration, and industrial) plant applications where high pressures and temperatures require pressure reduction only.

| Tel: | +27 11 249 6700 |

| Email: | [email protected] |

| www: | www.acs-autocon.com |

| Articles: | More information and articles about Automation Control Solutions |

© Technews Publishing (Pty) Ltd | All Rights Reserved