When accuracy, repeatability and low drift are considered as `basic' requirements for a high precision instrument, customers turn their focus to areas of safety. Improved operational safety and production safety are becoming more important in not only enhancing working conditions, but also in maximising return on assets (ROA).

Endress+Hauser believes it has taken safety to a level where customers can absolutely rely on their measuring points with the newly released pressure and differential pressure devices, Cerabar S and Deltabar S. Ensuring that a pressure measurement point will operate safely. These devices employ a safety concept that starts with a clear, concise, plain text, menu guided operating system, which guides the user through the set-up of the transmitter, ensuring that all the required parameters are correctly configured.

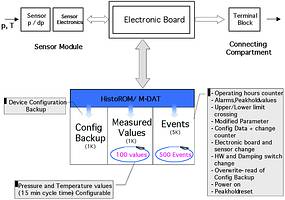

The transmitters also have a memory module on board that stores all configuration data and events, like over-temperature and over-pressure, as well as all configuration changes, operating hour counter and 25-hour (25 hours at 20 s intervals, averaged and recorded at 15 min intervals) process recorder. (Figure 1).

Endress+Hauser designed its new pressure transmitter according to SIL (safety integrity level) IEC 61508. This standard is based on the argument that a product may be either produced or tested to be safe (proven in use). Functional safety requirements, however, do require safety-relevant components of protective and control devices to function correctly. When a fault or failure occurs, the plant or system must either remain in a safe condition, or be brought to a safe state.

Functional safety covers all aspects regarding incorrect behaviour of control systems, machines and personnel, to reduce the risk to man, environment and machines by means of fault prevention and system-fault control. There are three main fault groups, with the first being 'safe fault'. A safe fault could, for example, be if the display of the pressure transmitter fails. This has no effect on the continued and safe operation of the plant.

The second type of fault is classified as 'dangerous fault detected'. This could be if there is a faulty sensor in the pressure TX, for example. The sensor would identify the fault and notify the system, thereby having no effect on safety. Quality, modern day devices feature this as standard.

The third and most dangerous fault is 'Dangerous Fault Undetected'. Here, an example would be when the output signal from the TX is fixed anywhere within the 4...20 mA range and is no longer dependent on the process variable. The plant operator or system assumes the signal received is correct and, therefore, does not detect the fault. This has a huge impact on safety.

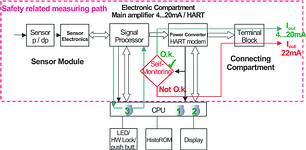

Endress+Hauser believes that the only way to overcome these safety risks is to design an instrument that conforms to all relevant safety requirements, as described in Figure 2.

In the displayed scenario, the transmitter has a complete ram/ROM self-check feature, as well as a self-diagnostic signal processor with an independent secondary measuring path for validation, ensuring the integrity of the output value and, thereby, guaranteeing the safety of the measuring point.

Secondary containment was yet another issue taken into account when Endress+Hauser designed and developed the new pressure range. The enhanced mechanical integrity of the design ensured that, even if the process-diaphragm is ruptured, process conditions are contained. Other inherent safety features include high temperature resilience of up to 280°C, without the use of chemical seals.

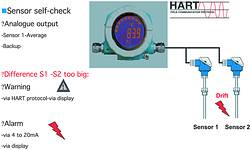

Intelligent safety features are also present on the TMT162 temperature transmitter, which offers accuracy within 0,1k, and long-term repeatability of 0,0015%. The transmitter features dual inputs with automatic, hot swap-over functionality and alarming, to ensure that the process is not interrupted should one of the temperature probes fail.

The TMT162 also features drift warning. Drift warning is achieved by using a single TMT 162 with dual inputs that are wired into two measuring sensors, installed in the same point in the process. The electronics will measure the input signals and alarm via HART protocol and the display when it detects drift in either of the sensors. This, once again, allows the process to continue uninterrupted, while ensuring that the operator or the control system is aware that the signal it is receiving is not the correct process value. (Figure 3).

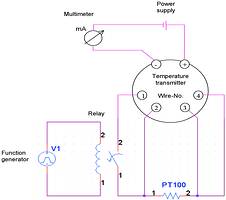

Also designed to meet SIL 2 requirements, the TMT162 is a leader in its class, with corrosion detection to ensure the integrity of the entire measuring point for RTD and thermocouples. A leading global chemical company voted the product 'Best in Class' in detecting high-frequency intermittent contacts caused by loose wiring. (Figure 4).

Other safety features include built-in diagnostics, including stored min/max values of both sensors, as well as ambient transmitter housing temperature, and a static revision counter, as required by the FDA 21 CFR, Part 11.

For more information contact Grant Joyce, Endress+Hauser, 011 262 8000, [email protected], www.za.endress.com

| Tel: | +27 11 262 8000 |

| Email: | [email protected] |

| www: | www.endress.com |

| Articles: | More information and articles about Endress+Hauser South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved