Measuring temperatures accurately in manufacturing operations has become increasingly important in recent years. Excessive temperature changes can indicate process problems or some kind of existing or imminent equipment failure. At the same time, using thermocouples and other contact measurement techniques is often impractical.

Targets have shrunk; increasing the error introduced by contact methods, where sensors drain heat from the objects they are examining and thereby disturb the very systems they are trying to measure. And, of course, many applications prohibit contact altogether. Thus the transition towards non-contact temperature measurement is increasing.

In addition to the increasing demand for non-contact alternatives, the methods themselves have advanced. Sensors have shrunk, analysis hardware and software have improved dramatically, and prices have dropped. As a result, more and more manufacturers are choosing non-invasive temperature measurement. By all indications, this trend will continue. All objects emit infrared radiation that corresponds directly to temperature. Measuring temperature accurately without touching an object requires detecting this emitted energy and compensating for any stray energy reflected from surroundings. The amount of the reflected energy depends on the object's emissivity, a measurement of how reflective it is.

The basic design of an infrared temperature measurement instrument includes a lens to collect the energy emitted by the target, a detector to convert that energy into an electrical signal, an emissivity adjustment, and an ambient temperature compensatory to reduce measurement error. Selective filtering of the incoming IR signal has dramatically improved the design. More sensitive detectors and more stable signal amplifiers allow the elimination of interference from extraneous environmental conditions.

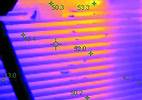

Infrared temperature measurement enjoys wide use in process control. In steel mills and other operations where high temperatures prohibit contact techniques, and in applications involving high-voltage equipment or corrosive solutions, the non-contact advantages are obvious. But even in relatively well-behaved processes, temperature mapping can pinpoint hotspots and other anomalies that may indicate processes not in equilibrium, and therefore signal the need for intervention or corrective action.

One increasingly popular application of non-contact temperature measurement is in predictive/preventive maintenance (PPM) programmes. PPM uses the operation history of plant equipment and systems to schedule maintenance and thereby optimise overall plant operation.

Non-contact measuring products fall into two broad categories: simple sensors and thermal images. Simple sensors offer general information at a reasonable cost, but do not provide either high resolution or high measurement precision. A simple infrared thermometer may measure temperature and store values, but may not interface with a PC for longer-term data storage or for further analysis. Thermal images on the other hand typically offer a wide range of features at a higher price. They are renowned for high resolution and software to help manufacturers monitor temperatures precisely in critical processes or determine the likelihood of defects in equipment.

Between these two extremes, a new imager class is emerging that offers the measurement performance of the higher-priced products, but with fewer refinements at a more affordable price.

The first thermal imager in this price category is the ThermoView Ti30 by Raytek. The ThermoView Ti30 has a measurement range of 0 to 250°C. It can store 100 images, which can be manipulated off camera using the software supplied with the camera, included in the price.

It is the first thermal imager in its price category, to provide detailed thermal imaging and precision temperature measurement simultaneously.

The accompanying software is as important as the measurement instruments themselves.

With thermometers and other simple systems, the 'software' is an operator recording the readings on a clipboard for comparison with past and future results. Direct software control of the imaging system allows the capture and analysis of numerous areas of interest at high speeds. An upload of previous images allows images captured from prior tests to be reviewed. By viewing the before and present image the users can determine the point of product failure or the time frame when a process exceeded specification limits.

In many manufacturing applications, non-contact sensors provide a better solution for temperature measurement thus the move to infrared non-contact techniques will continue to accelerate.

For more information contact Steve Edwards, PREI Instrumentation Natal, 032 946 2805, www.prei.co.za

© Technews Publishing (Pty) Ltd | All Rights Reserved