Time-of-flight(TOF) and Doppler are the two most popular types of ultrasonic flowmeters in use today for closed pipe flow measurement. Most suppliers provide TOF type devices. TOF flowmeters make use of the difference in the time for a sonic beam to travel a fixed distance, first in the direction of flow and then against the flow. TOF is used for measuring liquids virtually free of solid or entrained gases.

Doppler devices on the other hand make use of the Doppler frequency shift caused by sound reflected from moving particles, solids or gas bubbles in the flow path. In general, Doppler flowmeters are less accurate than TOF flowmeters.

Advanced digital signal processing has enabled the development of hybrid ultrasonic technology for measuring clean liquids which periodically have significant amounts of entrained solids and gases. This technology enables the measurement of multiphase flows, however, the overall accuracy is lower than that of TOF devices.

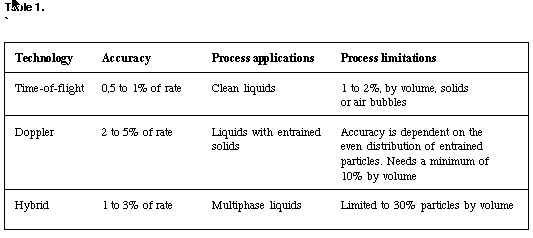

A summary of the main limitations for each technology is listed in Table 1.

Differentiating TOF from Doppler and hybrid

Time-of-flight (TOF)

A time-of-flight flowmeter (Figure 1) measures the effect of a liquid's flow velocity on bi-directional sound signals. An upstream transducer sends a signal to a downstream transducer which sends the signal back again. When there is no flow, the time taken from the up transducer to the down transducer is exactly the same as the time going from the down transducer to the up. However, when there is flow, the liquid's flow velocity assists the sound beam in the upstream to downstream direction and dampens the sound beam in the downstream to upstream direction. This creates the time difference by which the liquid's flow velocity and, ultimately, the flowrate is determined.

Doppler

A Doppler flowmeter (Figure 2) uses two transducers, one to transmit and another to receive, to create the flow measurement. The transit transducer injects an acoustic signal into the flowstream at a specific frequency. This signal reflects off entrained air bubbles and solids and is detected by the receive transducer. The flowmeter compares transmit and receive frequencies and computes the frequency shift. This frequency shift is proportional to the liquid's flow velocity.

Hybrid

The hybrid technique (Figure 3) also uses two transducers, one as a transmitter and the other as a receiver. Ultrasonic bursts are transmitted into the process at a rate which is much faster than conventional TOF techniques. The rate is fast enough so that the distance a bubble or particle travels is much less than the beam width of the transmitted burst (for normal flow velocities, 1 to 10 m/s). This allows the bubbles or particles to be identified by many sequential bursts. When the sound from each burst encounters these objects, some of the energy is reflected from the objects and detected by the receiving transducer.

As the particles in the fluid stream change position, the reflected energy received at the receiving transducer shows a slight change in transit time. This transit time is used to calculate the velocity of the bubbles and other particles and, therefore, the overall flowrate.

Wetted sensor and clamp-on construction

Ultrasonic flowmeters used for measuring flow in closed pipes are segmented into two groups: wetted sensors and clamp-on sensors. Wetted sensors are almost always supplied as part of a spool, whereas clamp-on sensors, as the name implies, are supplied with a variety of external pipe clamping devices. These include velcro tape, tension chains, magnets and brackets etc.

Wetted sensors vs clamp-on

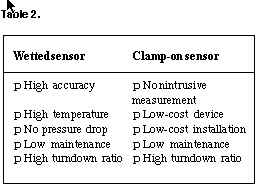

The requirements of each application typically define the adoption of one type or the other. The main features of each type are given in Table 2.

Single-beam and multibeam flowmeters (wetted sensor)

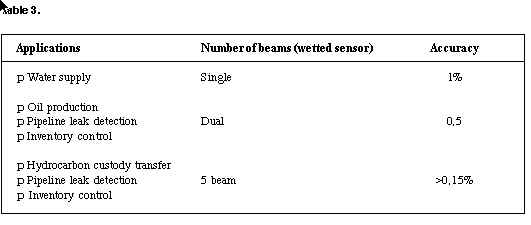

The number of sensors used to scan a flow profile dramatically increases the flowmeter accuracy. A single-beam flowmeter with diametrically positioned sensors scans the flow profile once at the pipe diameter. The resulting measurement represents the average fluid velocity inside the pipe.

It also assumes that the flow profile is evenly distributed (ie the flow is turbulent). As a result, the accuracy is, at best, 1% of rate.

A dual beam flowmeter, with sensors positioned at slightly above and below the diameter point, will have a higher accuracy, by definition, as the flow profile is being scanned in two places. Uneven flow profiles (due to Reynolds effect) have less impact on accuracy because the scanning area is greater.

Five beam flowmeters with beams on the diameter and chordal points deliver accuracy in the range of 0,1 to 0,15% of flowrate. This is possible because the flow profile is scanned in smaller sections and thus accounts for all flow profile differences.

Customers specify the number of beams in the flowmeter based on application and product characteristics.

| Tel: | +27 11 314 1391 |

| Email: | [email protected] |

| www: | www.za.krohne.com |

| Articles: | More information and articles about KROHNE |

© Technews Publishing (Pty) Ltd | All Rights Reserved