System's Integrators, SAM (System Automation and Management), have installed a technologically advanced Adroit supervisory control and data acquisition (scada) system at the Gold Fields/IDC Living Gold Rose Project in Carletonville.

The water treatment plant was designed, installed and commissioned as a turnkey project by Keyplan, a leader in the water treatment field in South Africa. The ultrafiltration (UF) and reverse osmosis (RO) plants are used to polish and desalinate treated sewage water respectively, which is used for fertigation (fertilisation and irrigation) at the Goldfields hydroponics rose farm. When complete, the Rose Farm Project will yield approximately 55 000 roses per day exclusively for export.

Monitoring of the water desalination plant is enabled by the Adroit scada system, which displays, records and alarms all necessary operating parameters and conditions within the UF/RO plant. Leon Bouttell, Project Manager for SAM comments: "Adroit was ideally suited for this application."

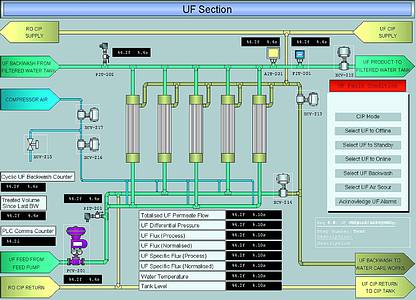

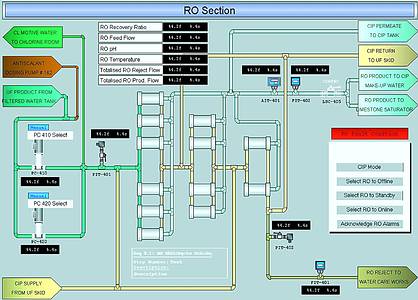

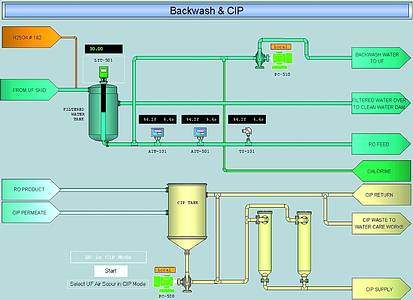

The plant is set up in two sections. The UF plant removes suspended matter as well as algae, bacteria, etc, to produce a disinfected, high quality feed water to the RO plant. Biological fouling in both the UF and RO systems is controlled by maintaining a low chlorine residual in the UF feed water. UF flux is maintained by automated and highly efficient Air Scour and Backwash operations. After pH correction and antiscalant addition the RO plant desalinates the UF product using robust and chlorine tolerant cellulose acetate membranes.

In the case of critical alarming, for example, if the RO or the UF plants go offline, an audible alarm is triggered through an audio device using a sound blaster card. Values are set in the Siemens S7316 programmable logic controller (PLC) that monitors and controls all alarm conditions and takes necessary trip actions. The scada picks up alarm data from the PLC and opens an alarm page on the workstation and activates the audible warning if required. By setting up the alarm parameters in the PLC, SAM have ensured that the operator must acknowledge the warning before the plant processes can proceed.

The plant purifies 59 m3/h of treated sewage water from the Oberholzer Water Care Works, or rainwater from the run-off of the greenhouses, producing 50 m3/h of high quality, low total dissolved solids (TDS ~ 50 mg/l) permeate. Product post-treatment includes limestone stabilisation and de-chlorination.

Limestone stabilisation increases the RO product water alkalinity, which provides an improved buffering effect, while activated carbon removes residual chlorine from the product water by adsorption. The height of the two Limestone Saturator outlets is set to allow flow to two 495 m3 storage tanks. When these tanks are full, the post-treated product can overflow from the limestone saturator to the clean water reservoir, from where it is pumped to the fertigation system that currently supplies Gold Fields approximately 150 000 rose plants and is set to provide for as many as 800 000 plants in the near future.

The RO Recovery is approximately 85% and the 9 m3/h of surplus concentrated brine produced is piped back to the discharge stream of the Water Care Works about 1,5 km away from the RO plant. Designed for a 20 hours operation daily, the plant's total production amounts to a million litres per day.

The Adroit scada is set to read all process plant values and write back set points and additional values, while five PID controllers are programmed with parameters that control functions, for example, tank levels are monitored by the Adroit scada and the UF production rate is controlled by the PLC via a flow control valve to keep in pace with the RO demand.

The Inat OPC server allows the third party MPI2/serial interface on the PLC to connect with the Adroit scada. The Inat adapter converts the signal to MPI format and the PC workstation in turn communicates with the OPC driver via communication cable connecting the PC serial port to the PLC serial port. The trending function in the Adroit scada is used to track approximately 35 variables such as pressures, flows, tank level, pH and controller outputs. Historical trends are stored for about one month on a hard disk using the Adroit database.

Workstation graphics were created by SAM who used objects for the pumps and variable speed drivers (VSDs) in different colours to indicate the operational status of the plant. Green, for example, indicates that the plant is running, blue to show that it is ready to start, and red to indicate a hardware problem. The same colour coding was used to indicate the status of the plant's numerous valves.

Paul Cecchi, who was actively involved in the installation of the scada and other components of this three-month project comments, "Adroit was very easy to use and because it is a local product, Adroit offered excellent support and access to the original developers."

| Tel: | +27 11 658 8100 |

| Email: | [email protected] |

| www: | www.adroitscada.com |

| Articles: | More information and articles about Adroit Technologies |

© Technews Publishing (Pty) Ltd | All Rights Reserved