Saab TankRadar Pro Steel and Saab TankRadar Pro Hot are non-contacting radar level gauges suitable for the metallurgical industry and its harsh environment. Pro Steel and Pro Hot solve several level measuring problems and are a key to high quality production because of high performance, non-maintenance operation and total reliability.

Saab Rosemount Tank Control has 20 years of experience of radar gauging in the steel and iron industry and the equipment has been continuously developed to suit the market. In the case of the Pro Steel and Pro Hot, high signal to noise ratios and the specialised antennas have improved reliability. Applications include: blast furnaces, torpedo cars, open ladles, converters, rotary coolers, oil fuel tanks, smelters, and other liquid metal vessels.

Features/advantages include:

* Radar's high accuracy level measurement.

* No moving parts and no contact with the product.

* No regular maintenance.

* High reliability.

* Insensitive to heat and dust.

* Ensures safety.

* High sensitivity and unique signal processing features cater for difficult process conditions.

* Specialised antennas with effective cooling and purging devices suitable for high temperatures.

* No recalibration.

* Interactive set-up with Windows-based PC software or via local display with keyboard.

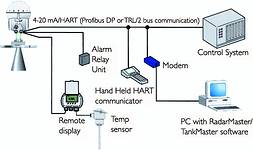

* Analog 4 to 20 mA superimposed with HART, and digital Profibus DP, Foundation Fieldbus or TRL/2 bus outputs.

Pro Hot

Pro Hot has a short cone antenna with purging, Pro's standard wave-guide connection and digital signal processing using FFT and the Echofixer (and the optional FHAST) software modules. During charging it does not have the extended range of the Pro Steel radar but is a lower cost solution that still offers reliable measurement suitable for normal operation. Pro Hot is intended as a best alternative among the lower costing radars.

Pro Steel

Pro Steel has a special extended cone antenna design, a cooling and cleaning device and a more robust wave-guide connection. It runs Pro's digital signal processing software modules and has an optional housing for cooling and protection. Pro Steel performs over extended measuring ranges, elevated temperatures, and is suitable for both normal operation and furnace charging/emptying - and is resistant to 'dirty' environment.

TankRadar Pro can be equipped with a number of different output alternatives: analog 4 to 20 mA HART, Foundation Fieldbus (FF), Profibus DP or Saab's Modbus-based TRL/2 fieldbus. The analog outputs are either passive for connection to powered cables or active providing signal power for display units etc. Analog outputs can also be specified to be intrinsically safe.

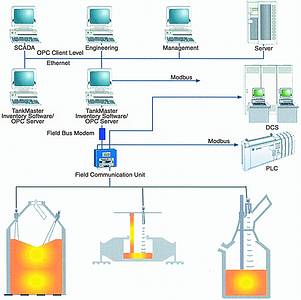

When using the digital TRL/2 bus outputs, up to 12-15 gauges can be connected to each two-wire fieldbus, maintaining a high data updating speed. Each fieldbus is connected to a field communication unit (FCU) that handles up to four fieldbuses with data from a maximum of 32 gauges. Several FCUs can be installed to handle a large number of gauges. Data from the FPU can be transmitted on RS232/485 or TRL/2 bus formats to host computers (DCS, PC or PLC). Pro gauges with TRL/2 bus outputs can also be connected to the TankMaster operator software providing an OPC server that can be linked to the plant network. Data is displayed on the optional 2210 Display Unit mounted on the gauge - or separately, via the separately mounted display. Up to six temperature sensors can be connected to this.

Configuration may be performed using a HART communicator, 2210 Display Unit or with a PC using the Windows-based RadarMaster software package. RadarMaster includes advanced graphics software tools, including FFT disturbance echo tracking. TankRadar Pro can also be connected to the FF bus among any other type of instrument. Up to 16 Pro gauges can be connected to each FF segment. Pro can be configured from any FF host system.

Application examples

Blast furnaces - stockline detectors

The use of non-contact and maintenance free level measuring equipment in the blast furnace is essential to ensure the correct level for loading material at all times. The furnaces can be equipped with either one or several transmitters. Pro Steel and Pro Hot are suitable for both 'Bell-Top' and 'Rotating Chute' blast furnaces and is not affected by the chute.

Torpedo cars - automation of filling

The installation of Pro Steel or Pro Hot for the measurement of the iron level in torpedo cars during filling, optimises the use of the torpedo car fleet. It reduces the number of overfilled or underfilled transports to a minimum. If the level values are sent for example to a DCS system the filling of the cars can be controlled and optimised. The data can also be displayed on an optional 2210 Display Unit mounted on the gauge or separately.

BOF or LD converters - improved lance positioning

Pro Steel installed for bath level measuring in a Basic Oxygen Furnace or LD converter results in improved process control. The exact level is determined by sending the microwaves down to the surface, where they are reflected back to the transmitter. The transmitter can be mounted as fixed or mechanically movable to a measuring position. It takes less than 10 seconds to set an accurate reading even if installed on a movable mount. Accurate level information ensures optimal positioning of the oxygen lance, and gives more information about estimated blowing time. High temperatures, smoke and dust do not affect the function.

For more information contact Luculle Stols, Alpret Control Specialists, 011 249 6700, [email protected], www.alpret.co.za

| Tel: | +27 11 249 6700 |

| Email: | [email protected] |

| www: | www.acs-autocon.com |

| Articles: | More information and articles about Automation Control Solutions |

© Technews Publishing (Pty) Ltd | All Rights Reserved