In the field of connecting electrical conductors recent years have seen spring cage technology steadily gaining ground against traditional screw terminal technology. At the same time a means has been sought to enable terminal block connections to be disconnected and reconnected without having to disconnect the wires themselves. A solution was developed.

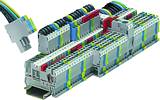

Time and again engineering companies are faced with the same dilemma: a facility or machine is constructed and tested, but then needs to be dismantled and moved to the location for which it was intended, where it has to be assembled all over again. All the wires that were connected have to be disconnected from their terminal blocks, and then reconnected at the new site. This takes time, contributing needlessly to the cost of the whole exercise. This has caused many system designers to look for a solution where the required separation points are built using plugs. Ideally, they would also like to keep fixed connections for the terminal blocks to use, in order to continue benefiting from the advantages of spring cage technology. This need is now being met by the ST-Combi product family from Phoenix Contact, which effectively offers a combination of ST spring cage terminal blocks with a plug contact (see Figure 1).

Space-saving design

The mini-spring spring cage concept from the ST range has been integrated into the ST-Combi terminal block, with the result that the pluggable terminal block also offers additional space savings in the control cabinet. Ideally, the compact design should not compromise the good features that users of the connectors up to now have come to enjoy. A large labelling area must still be available and the connection space for the wire must still be as generously proportioned. Application-oriented distribution requires a flexible bridge plug system, if it is to become popular.

Universal accessories

In an application it is often the case that only part of the design needs to be pluggable, the rest being conventionally connected as previously - so all connection points of the terminal are hard wired. This requires different terminal types. It is then of particular advantage for users if they can continue to use standard connecting parts. The ST-Combi system is equipped with the same bridge plug system as the ST terminal blocks. This allows the same bridges to be used for power distribution and the pluggable wiring can be combined with conventional wiring without limitations.

For both systems there is a universal labelling groove in the centre of the terminal. This offers sufficient space for one common labelling system. The labelling plate, integrated into the centre, is large enough to enable the application of group identifiers or special characters. The same bridges and the same labelling system are used for the accompanying plugs as well. This multiple application, as well as the application-oriented architecture, also results in a savings potential for storage and in the structure and maintenance of the parts list system.

Whether straight through, three or four-wire terminals, in pluggable or conventional design, all can be used flexibly with one another without needing to change the bridging or labelling concept. This gives users the freedom to design the installation according to their requirements.

Maximum connection space

A terminal block's wiring space is particularly important for efficient, fast wiring of different types of wires. This is equally true for the base terminal as it is for the plug. A spacious connection area facilitates wiring and saves installation time. The wire feed guides are designed to take flexible wires with nominal cross section - even with metal end sleeves and insulating collars. This makes it easy and secure to wire pre-assembled wire ends and cable harnesses.

Strong contact

The heart of a spring cage technology plug system is not the connection point, but rather the plug contact. A new, strong contact has been used for the ST-Combi range (see Figure 2). The rated line current of a 2,5 mm2 wire is pluggable without restriction as the ST-Combi system allows 24 A at 500 V. The standard pitch size is 5,2 mm. This makes one system available for signal and power wiring. The contacts are resistant to extreme vibration and the system has been successfully tested to a standard allowing for rolling rail traffic. During this test, the contact is checked for interruptions longer than one microsecond when subject to shocks and vibration. The plug contact in the base terminal and the plug itself are protected against direct finger contact in accordance with the BSV A2 regulation.

Diverse product range

The pluggable base terminals are available as straight through, four-wire and double-level terminals. For each type there is a protective earth terminal with the same contours. There are various plugs for different requirements, for example, there is one designed for connecting one wire. A second version additionally allows plug bridging for potential distribution. The third plug type is designed for connecting two wires with a bridging capability. All three plug-types are available in pin counts from one to 115 and allow individual composition.

There is a comprehensive accessory program for use as required. For example, there is a coding system that ensures plugs can only plug into the base terminal in the correct position. Certain applications require an additional locking device for linking the plug to the base terminal. This is available, as is a strain relief (see Figure 3). Both accessory parts can be plugged into the plug as required. The accessory program is rounded off with an attachable connection for screened cables.

Conclusion

The new ST-Combi plug system based on spring cage technology offers flexibility that will accommodate new approaches in assembling and wiring of modular components - an efficient overall wiring concept.

| Tel: | +27 11 801 8200 |

| Email: | [email protected] |

| www: | www.phoenixcontact.co.za |

| Articles: | More information and articles about Phoenix Contact |

© Technews Publishing (Pty) Ltd | All Rights Reserved