During the 1990s, automation of control valves, often referred to as ‘the final control elements’, got the world’s attention. We learned the meaning of a new vocabulary. ‘HART’, ‘intelligent positioner’, ‘predictive maintenance’ and ‘fieldbus’ were the words we read about in almost every article and product description. We almost never discussed the automation of on-off valves.

The term 'final control element', as we often use for control valves, relates to the control valves as being the active component in the flow loop. Associated with the active component are various passive components, such as pressure, flow and temperature transmitters. These passive components cannot control the flow.

During the 1990s control valves acquired new functionality with the implementation of digital control. In addition to the improved control there was also a tool to be used for predictive maintenance. Although control valves are very important for the quality of the final product, the automated on-off valve can be as important when it comes to costs for unexpected disturbances and emergency shutdowns of a plant. Therefore the automated on-off valve also should be considered to be a 'final control element'.

Control vs on-off valves

The proportion between control valves and on-off valves can vary a lot depending on the type of industry. When asked about the relationship between control and on-off valves, staff in a typical pulp and paper plant identified 40-60% of all automated valves as being on-off valves. When asked the same question, staff at one of the biggest Swedish producers of vegetable oils, mentioned that 300 out of approximately 20 000 automated valves in their plant were control valves. This equals to approximately 1,5% of all automated valves being control valves, thus leaving 98,5% as on-off valves.

Whatever proportion we have between control valves and on-off valves, it is certain that on-off valves play important roles in plants. Therefore the overall automation of on-off valves is very important.

Traditional on-off valves

Traditionally, an on-off valve has been equipped with limit switches and a solenoid valve. By means of the solenoid valve the pneumatic actuator can stroke the valve. The limit switches are used to monitor the valve position in the DCS system. The function of the valve is purely an on-off function. This is still the way on-off valves are used. The only recent development is the introduction of simple fieldbuses like ASi. These are essentially simplified wiring implementations. No added functionality has been gained.

Intelligent on-off valves

With the introduction of the NAF-SwitchIT intelligent on-off valve controller from NAF, a completely new technology has been brought into quarter-turn on-off valves. Taking advantage of true two-way communication, they feature on-line valve diagnostics as well as alarms.

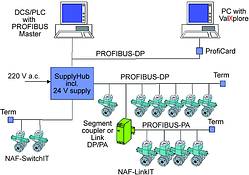

The NAF-SwitchIT is based on the PROFIBUS-DP fieldbus. PROFIBUS-DP is probably the most proven fieldbus on the market. It allows up to approximately 120 SwitchIT units in one network. NAF-SwitchIT is based on technology developed by another Invensys company, APV and over 20 000 units have been installed, one plant alone having 1500 valves.

True, two-way communication permits on-line valve diagnostic and alarms. With the help of ValXplore software, all valves in the network can be identified, monitored, configured and diagnosed.

Increased functionality

Of the new features, perhaps the ramping feature is the most revolutionary. There are at least two different types of applications where ramping can be used. The first, and perhaps most obvious, is to avoid water hammer effects. In numerous applications opening or closing of a valve causes severe pressure shocks in the pipeline. These pressure shocks can cause failures in the valve, in other components or in the pipeline itself. In the worst case, the pipeline will burst, resulting in a free outlet of the medium into the atmosphere. Not only will this result in a costly emergency shutdown, but also in a potential environmental and human catastrophe.

The ramping feature can also be used to limit the valve opening. In many applications today, a control valve must be used if the valve is intended to be left in the same position for a long time. This can now be done with an intelligent on-off valve. In fact, with the introduction of the ramping feature, the border between control valves and on-off valves is becoming less distinct.

Savings

Potential areas where savings are to be had include simplified cabling, documentation and start-up. It all depends on the type and size of installation, geographic distribution etc. This should not be the single reason for choosing intelligent on-off valves. The real savings exist in minimising emergency shutdowns and access to increased functionality. It is all a matter of taking control over your on-off valves.

The NAF website is www.naf.se - Valve & Automation is the sole South African supplier of these NAF products.

| Tel: | +27 31 579 2593 |

| Email: | [email protected] |

| www: | www.valve.co.za |

| Articles: | More information and articles about Valve & Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved