The possibility of placing control function blocks in field devices is an important feature of Foundation Fieldbus technology, but what does it mean in practice? This paper (presented as a series of articles) takes a look at the advantages and limitations of control in the field, with illustrations from a recently completed installation.

Who is afraid of control in the field? It is an indication of how far control technology has progressed in the past decade, that most control engineers, if not admitting directly that they would not use it, would at least express reservations. This is an opinion confirmed by many salesmen: “When we are selling Foundation Fieldbus, control in the field is not a big issue – in fact we avoid mentioning it where possible”.

One reason for this scepticism might be that many first-wave fieldbus users are migrating from a distributed control system (DCS) or programmable logic controller (PLC) environment, based on analog instrumentation, where powerful controllers are traditionally located remote from the field. Many will already be operating and monitoring their process from a central control room. Those who are not have probably selected fieldbus technology to realise such a scenario. One of the benefits of fieldbus technology is improved information flow, and where better to acquire, collate, evaluate, act upon and store it than at a central location: is that not where the intelligence, man and machine, is located?

Since monitoring, operation and control are today perceived as part of the same activity and often executed by the same people, proposing control in the field appears to be contradictory to fieldbus philosophy. This is false. Control in the field offers more flexibility and cost efficiency in system design, and when implemented properly, more security and better optimisation of process control.

Back to the future

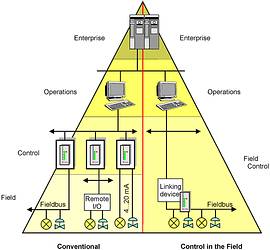

In the early days of process automation all control was distributed in the field (see Figure 1). Every control loop had its own pneumatic (later analog) controller. Each control 'loop' could be physically seen: the measuring device, the air piping going to the controller and the air piping going to the control valve. Instrument technician, operator, process control 'engineer' were all one and the same person.

In the 'sixties, mainframe computers made their way into administrative departments. Soon the process control engineers started dreaming of using this technology for controlling their plant. Hopes were high: every possible control algorithm should be put into the computer to lift the level of process control. Despite enormous investments on both supplier and customer sides, however, mainframe 'central' process control computers were doomed to failure. The most obvious reason is that the 'central' mainframe computers did not have the MTBF (mean time between failure) required to control a process environment. A second, but maybe even more important reason was that all intelligence had to be 'programmed' into the computer. Everything, from the simplest PID control algorithm to the most complex control schemes had to be written in programming code before it could be executed. The complexity of such process control programs was simply too high to be practical.

In the 'seventies, distributed control systems (DCS) made their entry. Cheap microprocessors made it possible to distribute the process control over a number of autonomous process control modules each controlling a limited part of the plant. This clearly resolved the problem of reliability. The second problem was also addressed by these DCS systems: the systems became configurable! Pre-programmed modules were now available to execute simple and more complex process control tasks.

The fact that DCS systems are configurable is of great importance when discussing 'control in the field'. During the years that followed their introduction, DCS systems were used throughout the most diverse process industries in both continuous and batch applications. Exposure to these different control environments made them increasingly mature: hundreds of configurable modules for every possible control problem were developed and stored in the system library. (A similar development could be observed in the PLC market, where demands centred on sequential and centralised process control.) This also differentiated the various DCS systems. Some were more exposed to chemical process control applications while others were typically used in the electricity market. Some systems had a high exposure to complex batch applications with a lot of discrete control. High demands on historians and alarming were typical for yet another process industry.

In the following years the hardware became even more reliable. Redundant systems were developed on both the process module and communication sides. Soon process controllers were able to handle tens, hundreds, even thousands of control loops without jeopardising the reliability of the complete system. Distributed control was the name, but in reality the degree of distribution was being constantly lowered. In fact, DCS systems became synonymous for 'easy to configure' (pre-programmed) but proprietary process control computers that fitted perfectly the needs of the process control industries by providing an inexhaustible library of control blocks with many parameters.

Finally, in the 'nineties, people started 'digitising' the missing link between the process controllers and the field instruments. The fieldbus idea began to get supporters. Two camps were formed: fieldbus with control in the field (Foundation Fieldbus) or fieldbus without control in the field (Profibus). Field devices would become intelligent and equipped with microprocessors. Control could once again, like in the old days, be distributed in the field.

Ten years on, with Foundation Fieldbus a reality, control in the field is struggling for acceptance. One obvious reason is lack of power: DCS vendors are, understandably, unwilling to pool their well-matured control blocks in an open standard. There must be other reasons, however, because: single loop controllers are still sold in large quantities, proving that there is a market for these simple applications. A lot of customers need a low level of automation that can be provided by a number of single loop controllers with simple PID algorithms. The 'angst' is not for the concept, therefore, but for the change from a paradigm that has dominated process control for the last 20 years. This fear is also extended to a certain extent to fieldbuses in general.

Control hierarchy mindset

Despite the increasing interest shown in fieldbus technology, it is safe to say that the majority of today's DCS and PLC-based control systems use 4-20 mA signals to realise continuous control. In view of the fact that these signals carry no information other than the measured value, there is a natural separation between the control and field level as regards the functions performed (see Figure 2). Sensors provide the process value, controllers derive the action, and actuators realise the action and provide feedback. Since there is a standardised interface between controller and field device, the user has freedom of choice in the equipment he uses and can benefit from a corresponding reduction in costs.

When the microprocessor appeared in the late 'seventies, it not only revolutionised DCS systems and made possible today's PLCs, it also spawned a new generation of intelligent field devices that offered much richer process information than could be transmitted via 4 to 20 mA signals. Fieldbus devices were first exhibited in 1989, and not long afterwards, the ISA SP50 committee was formed to write the specification for a new, universal fieldbus. Obviously, the new standard had to offer the same freedom of choice as analogue technology, thus not only was a communication interface required, there also had to be a standardised user interface. This was to be realised by function blocks, the eighth layer on top of the ISO model.

Forgetting the so-called fieldbus wars, it is interesting to note that Profibus, the rival fieldbus standard that emerged directly from SP50, uses essentially the same function block process as Foundation Fieldbus. The major difference lies in the possibility of embedding control blocks in FF devices. In view of the fact that the role played in Profibus controller/device interaction fits so neatly in the traditional control hierarchy, however, the function block application process has never been an obstacle to sales. It was only a gradual change to a new paradigm but not a radical one. Customer concerns are those shared by Foundation Fieldbus: certification, integration, interoperability and the fieldbus itself.

Foundation Fieldbus devices can, of course, be made to fit into the traditional control hierarchy as peripherals of a DCS system. No doubt many of the systems sold to date do just that. It is, however, ducking the issue. If intelligence is already available in the field because practically all field devices have a microprocessor driving the measurement and communication, why do we not make full use of it? Control in the field has decided advantages, and any customer fears must be addressed and shown to be unfounded. When the facts are on the table before him, the user can still decide to operate traditionally, but at least he has made an informed choice.

Hocus pocus

It is always difficult for users to take risks and overcome the barriers that the adoption of a new technology inevitably throws up. It is still more difficult when 'old dogmas' still hold stakes in the ground. It should also be admitted that at this stage of the game, some solutions currently on offer are not ready to compete in a completely new fieldbus scenario. It is not surprising; therefore, that many potential users are hesitating. Typical reactions are:

* I do not know how to use fieldbus in my plant.

* I do not feel comfortable enough to implement it now.

* I have concerns about fieldbus; therefore, I prefer to keep my plant conventional.

These reactions come even when fieldbus is the most viable solution. There are several concerns and fears caused mainly by a lack of knowledge and experience. Decisions regarding deployment of an emerging technology cannot be undertaken without an intimate understanding of the relationship between the technology and its limitations and advantages. It is necessary to train and support in order to ensure that the user has a positive experience. It is also very important for the user to seek a partner that understands all necessary elements for a successful fieldbus project, from concept, through implementation to deployment.

The arguments for using fieldbus solutions range from cable savings through expandability to simple commissioning. The real benefit to the user, however, is the quality of information provided during normal operation. Past experience has shown that innovative solutions are necessary if overall plant performance is to be maximised: when safe and economic production is the goal, it becomes hard to justify the continued use of dated technology. Not only does Foundation Fieldbus provide intimate knowledge of the devices in the field, it also provides a wealth of information from the control loop itself.

These benefits, however, are not to be had when fieldbus devices are used 'conventionally'. For years, users have bought HART devices but never used the communication because there is no financial disadvantage. For fieldbus devices, there is currently a price disadvantage that must be justified by operational benefits. Wait-and-see strategies are expensive. In this situation, return on assets (ROA) becomes just as important as return on investment (ROI). For Foundation Fieldbus, getting the best return on assets means committing to control in the field. Since process information is available at every part of the system, operation becomes simpler, more profitable and much safer.

There is no doubt the economic arguments for control in the field are convincing, but there is still an element of black magic in the technology itself. It must be seen to work, not only theoretically, but also in industrial environments.

For more information contact Grant Joyce, Endress + Hauser, 011 262 8000.

| Tel: | +27 11 262 8000 |

| Email: | [email protected] |

| www: | www.endress.com |

| Articles: | More information and articles about Endress+Hauser South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved