The time-of-flight (TOF) operating principle is fast gaining acceptance in diverse level measurement applications, as a result of several clear advantages over traditional methods. TOF instruments are not negatively affected by process conditions like high temperature, vacuum, changing and extreme pressure, agitation and turbulent surfaces.

They are also virtually maintenance-free, suitable for applications where probes would interfere with an agitator, eliminate the need for shut-off valves and related leaks by being top-mounted, are flexible and cost-effective and can be dry-calibrated in a workshop removed from the actual process. TOF systems require no verification procedures.

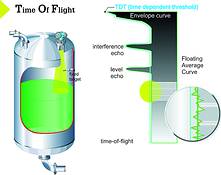

There are several choices available in TOF technology. Based on the measurement of time between the generation of a short electronic signal and its return following reflection from the process material back to the device, TOF is the operating principle for instruments using ultrasonic, radar and TDR (time domain reflectometry) technologies.

Except in the case of TDR technology, TOF systems require no probe or sensor to be in direct contact with process material. This is particularly useful in applications where chemical compatibility, abrasion, sensor build-up and application of mechanical stress by material movement are involved. In processes where excessive particle distribution (dust in silos) can cause interference, TDR provides the benefit of a wave-guide to direct the signal.

One of the reasons for instrumentation specialist Endress+Hauser's enthusiasm over TOF is the increasing demand for predictive maintenance in processes worldwide. TOF devices monitor build-up on sensors in order to be able to trigger an alarm when it reaches a critical point. Similarly, by monitoring the maximum temperature that a device is exposed to, overheated sensors can be exchanged before failure occurs, reducing downtime and maintenance costs.

Cost in itself is another factor in support of TOF technology. A major European chemical company compared a differential pressure transmitter and a radar transmitter by calculating the average cost for maintenance and repair. The results showed an annual saving per device of US$880. Like all other technologies, TOF systems have limitations. TOF sensor cleaning becomes an issue when sanitary requirements come into play, as contamination of new product through residue on the sensor must be avoided. In many cases, cleaning can be done through a preventative maintenance schedule.

When installing TOF devices, one must be mindful that all free-space systems (ultrasonic and radar) need an unobstructed line-of-sight. Turbulent surfaces caused by agitation, aeration, boiling, or simply filling, will also cause a reduction in signal return for all free-space systems. Such conditions can be accounted for by selecting a sensor one size bigger than that which would have been required under calm conditions.

To complete its attractive offering, modern TOF devices include features such as error and status messages, signal curve display methods and simulation modes that make troubleshooting quite easy. Endress+Hauser will continue to drive the development of these systems and devices to become more user-friendly and cost-effective, as it is clearly the technology of choice for most modern level measurement applications.

For more information contact Grant Joyce, Endress+Hauser, 011 262 8000, [email protected], www.za.endress.com

| Tel: | +27 11 262 8000 |

| Email: | [email protected] |

| www: | www.endress.com |

| Articles: | More information and articles about Endress+Hauser South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved