The performance and variety of level devices employing radar technology has significantly increased. For the first time, measurements within a millimetre of accuracy can be economically performed at individual measuring points in custody transfer, as well as in process engineering.

In industrial engineering, continuous level monitoring of liquids plays a critical role, representing approximately 12% of all measuring points. In recent years the trend has shifted to noncontact methods within level measurement, with the time-of-flight principle among the preferred technologies.

"Radar instruments using time-of-flight, initially, established prowess in high-precision tank gauging (custody transfer) applications, which presented ideally calm surfaces as reflectors. However, in process engineering the measurement situation differed, resulting in the eroding of the method's positive image," states Grant Joyce, Endress+Hauser spokesperson.

Factors contributing to this initial failing include: the new time-of-flight principle was often employed in problematic areas where previous contact methods had failed; manufacturers and users did not understand the limitations of radar; the extent of testing did not correspond to the actual needs of the operation; and, finally, some manufacturers quoted unbelievable ratings.

Manufacturers and users have learned their lesson, with developments focused on improvements to system performance. Five years ago the maximum accuracy of radar level measurement was ±31,5 mm, with the maximum process conditions at approximately 198°C and 6,4 MPa (64 Bar). Now, these values have improved to 3,17 mm, 400°C, and more than 16 MPa (160 Bar), accompanied by a more economical price per measuring point.

"Extremely accurate level measurement instruments without custody transfer features are increasingly used in the chemical industry. Radar systems with one-millimetre accuracy can now also be used in this respect. Their accuracy is based on an additional evaluation of the reflecting signals," states Grant Joyce, Endress+Hauser spokesperson.

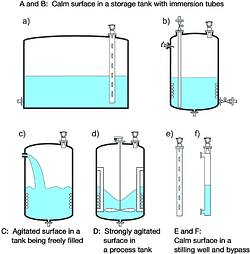

The product's surface condition is, probably, the most important application feature in the operation of radar level systems. A storage tank demands level measurement accuracy of 3,175 mm for custody transfer, while foam formation and splashing in interim storage and buffer tanks, places further demands on level measurement. For such applications, an accuracy of ±31,75 mm is sufficient.

Another class of process application involves agitators that cause strong turbulence on the surface. Here, agitator blades may cross the radar beam during measurement, requiring suppression of the resulting interference signals. Accuracy requirements are lower, but measurement accuracy is particularly important during the reaction phase.

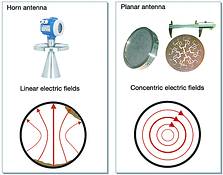

The significance of antenna technology is often underestimated. Antenna construction influences the performance of the overall system. A planar antenna for stilling wells, for example, is insensitive to the geometry and arrangement of slots, weld seams, build-up and rust during operation. Furthermore, by arranging the antennas concentrically it is possible to generate a propagation mode of electromagnetic waves that can be advantageously used in stilling wells.

Furthermore, the absence of seals, corrosion resistance, and the choice of material, play a significant role in obtaining various approvals. In aggressive media, fully PTFE-coated rod antennas are recommended, and have even received the FDA/3-A approval for sanitary and pharmaceutical process requirements.

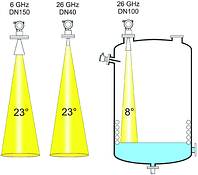

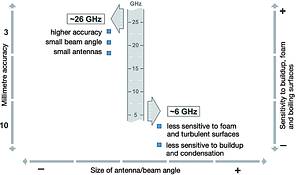

"The carrier frequency is a decisive factor in designing radar level measurement. A medium frequency of 10 GHz, for example, is insensitive to process conditions and has a small antenna/narrow beam angle," says Joyce.

A radar system with an operating frequency of 26 GHz is suited to applications requiring high accuracy and narrow beam concentration, such as those involving symmetrical baffles like heating coils. For small vessels such as those predominant in the pharmaceutical production, small horn antennas from 5,08 mm upward are used.

When foam occurs, lower frequencies (6 GHz) are better suited, but even so a trial measurement, due to the reflection properties of foam, is required. Both the size of the bubbles and the dielectric constant of the product are difficult to predict. Differential pressure measurement is recommended as an alternative in such cases. Heavy build-up of product on the antenna is yet another reason for using instruments with lower frequencies.

With an operating frequency of 6 GHz, planar antennas are recommended for stilling well applications requiring millimetre accuracy. In the stilling wells of large storage tanks, the holes and slots are arranged at random. The TE01 mode of this antenna offers high application safety under such conditions.

In standard and bypass applications 26 GHz systems have also proven their worth. With the former, the measurement conditions in the pipes are defined, making optimum accuracy achievable. Horn antennas can be easily shortened for stilling wells with interim sizes, adjusting each to the required dimension. Regarding the latter, 26 GHz systems are advantageous in their ability to distinguish reflections in the upper tank connection area.

Modern radar instruments are focusing on a uniform and comprehensive look and feel for the entire system, while assembly, commissioning and maintenance do not require special skills. Furthermore, many of today's radar devices, like Endress+Hauser's level instrumentation utilising radar technology, incorporate generous on-site displays with easy-to-follow menus, reports and alarms. Computer-aided tools also facilitate individual steps and offer context-sensitive help and explanations.

Grant Joyce, Endress+Hauser

011 262 8000

© Technews Publishing (Pty) Ltd | All Rights Reserved