The mining environment is one of the harshest environments in which to put instrumentation. Limited by vertical shafts, long distances and fragile cables data acquisition has always been difficult to implement in the mining environment. Omniflex has recently launched a new set of Maxiflex CPUs - the T1 and now the T2. These CPUs are intended for data acquisition and telemetry applications.

They require no user programs when used for data acquisition or telemetry application. They are simply plugged in, connected to field wiring and powered up. All I/O is scanned automatically and I/O status assembled into data interchange table (DIT). For digital inputs and standard analogs the input status requires no configuration at all, however temperature inputs like thermocouple and RTD require the sensor type to be configured providing input values in engineering units of °C or °F. Scaled analog inputs can also be catered for eliminating the need for an HMI to do any scaling to engineering units for 4 to 20 mA loops from the field. Adding I/O to the system has never been easier - simply plug in the new modules (hot plug-in - plug in while system is live) and plug-in the detachable wire terminals from the field. The new field I/O status is added to the DIT automatically.

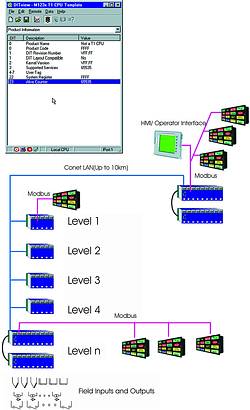

Configuration is easily made using a free Windows-based software package called OmniSet and a serial cable available from Omniflex. Simple selection of pull down options allows the user to configure the CPU completely. This configuration includes the ability to create multidrop telemetry systems using the Omniflex CONET Local Area Network up to 10 km on twisted pair cable. Configuration can also be done via an HMI if so desired, making a neatly integrated system controlled exclusively from HMI stations. Outstations, which may be up to 10 km away from the HMI, may be configured from the local HMI or PC connected to the network.

An HMI is simply connected to the Maxiflex T1 or T2 CPU via its auxiliary serial port that can be set to communicate using Modbus Protocol, one of the standard protocols on every HMI. The HMI now has access to any of the DIT registers on the CPU. In fact, if a Conet LAN is used, any data from the network is also accessible to the HMI - not just the local node. For mining applications this is a prerequisite - as getting underground is a time consuming process. Outputs may also be generated from the HMI to activate devices such as pumps, manually, as well as via application program. Other devices like alarm enunciators may also be used from the Modbus port to provide alarms and status indication underground or on the surface.

Maxiflex claims it provides a cost-effective solution to underground applications - as it simplifies the field I/O systems by eliminating the need to write time-consuming application programs for data acquisition or telemetry. Applications can also be included to automate pumps and fans. Maxiflex I/O systems cover analog inputs, voltage, current, thermocouple, RTD and digital inputs, potential free and voltages up to 200 V d.c., series contact chains, pulse inputs up to 50 kHz. Interfacing to third party RS232 or RS485 devices is a speciality with devices like intelligent circuit breakers or substation energy metering equipment etc. Given the communication protocol, Maxiflex will communicate with any of these devices. The Conet network topology can be used as a BUS, Star or mixed configuration allowing complex networks to be configured all on lowgrade plant cables. Omniflex has developed technology to cope with T-offs on networks, which typically relate to a vertical shaft and many levels, using Maxiflex network interface modules many levels can be added to the network without affecting the cable specification.

| Tel: | +27 31 207 7466 |

| Email: | [email protected] |

| www: | www.omniflex.com |

| Articles: | More information and articles about Omniflex Remote Monitoring Specialists |

© Technews Publishing (Pty) Ltd | All Rights Reserved