Modern scada (supervisory control and data acquisition) systems feature considerable flexibility and power, permitting applications where a wide variety of industries and applications can be monitored, controlled and analysed with this software.

One such industry is mining, where a number of subsystems have to be integrated into one view console to form a comprehensive overview of the mine (like reticulation, environmental monitoring, asset tracking, etc).

The SL2000 system that will be described in this article is an environmental monitoring system developed by SperoTek and used in several South African gold and coalmines. Its main function is to collect environmental parameters (like CO and methane gas, temperature and humidity, status of ventilation fans and dam levels, and many more operational parameters which are essential to the safe and effective operation of a mine) and then transmit these parameters via a telemetry network to a scada system. The scada used in this example is iFix from Intellution.

Integration of the system was done by the end-user (SperoTek). The scada is an integral part of the SL2000 telemetry system. The aim of the method of integration is to try and streamline it so that the addition or deletion of monitoring points can easily be made on-site. Usually the period of integration is a few days, not because of the difficulty of the process itself but because the plant or mine shaft cannot be put on hold to accommodate easy access to all installation points.

Support is simplified by deploying field-service personnel close to the areas where the systems are installed (eg Vaal Reefs and Witbank). A strong emphasis is also placed on backing up the system regularly and after every change to the system is made.

System architecture

About 200 tag points are used in the current system. Because of a continuing expansion of the system it will probably grow to double that. The system runs on Windows NT4 workstation with service pack five installed. When interfacing the SL2000 hardware with a scada system, the availability of a good OPC client is of utmost importance (although the telemetry system can interface with other I/O drivers, like Modbus). iFix seems to satisfy this need very well. Integration onto an intranet is planned for the near future. The networking support that iFix has built into it gives the user easy access to such requirements.

Graphics

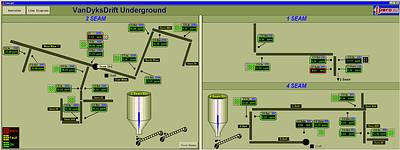

Figure 1 shows a screen capture of the main overview page of the system. It gives a quick summary of all sensor values, digital input/output status and the quality of the data being received from the telemetry system. Dynamos were created to simplify the task of adding additional measuring points to the page. This standard feature in iFix eliminated the task of duplicating similar graphic objects by hand. Figure 2 shows a graphical layout of the system. It shows the operator exactly where the measuring points are installed and also gives quick location references of possible alarm conditions.

Compatibility

The OPC server that is being used on the system has been operating with iFix since installation without any problems. iFix also has a useful OPC client tool, called the 'OPC power tool' that makes it very easy to configure the OPC addresses.

For a fire detection system like the SL2000, any dangerous condition (like high gas levels) must be reported reliably to the operator. Various scripts were written for this application, but alarming especially needed complex scripting. In this application an alarm condition should trigger a certain output on one of the field devices. The control and scheduling of these alarm conditions were written in iFix's powerful VB engine.

The power of iFix, for Spero's specific applications, lies in the fact that it uses Visual Basic scripting. This allows the developer to use his existing knowledge of programming to write an application that suits the end-user's needs best. The ease of graphical design (like animation) is also a very important feature that iFix addresses very well. In our opinion iFix has a very balanced focus over all aspects that make up a good scada package.

Spero Group

(012) 665 0317

© Technews Publishing (Pty) Ltd | All Rights Reserved