To this day the biggest problem facing companies in the automation and manufacturing layer of business processes is reporting. Even the most basic reporting on day-to-day operations, production and manufacturing data still remains difficult and unreliable.

Adroit Technologies has identified a huge opportunity in a number of market segments, namely the increased requirements for companies to be able to, through a single piece of software, conglomerate and analyse data from numerous data sources. Adroit Technologies has achieved and addressed this need through extraordinary domain expertise leveraged through a carefully crafted Internet solution.

The market being dealt with embodies growing requirements for owners of data sources such as supervisory control and data acquisition (scada), industry standard databases such as Microsoft SQL to extract, compare, and model data from various sources through an easy-to-use toolkit which in turn will present the data in a web browser on an intranet or over the intranet.

The generic term for such a product is a data portal. Opus's key differentiator is its very easy to use client side application and report generator. In the very near future the addition of a query builder and, along with its very powerful data modelling and analysis tools, will make it a leader in its class.

The product can thus be used in a variety of industries where there is a requirement for such data reporting and analysis. Further to this, the various functional departments within these organisations can build and execute their own reporting requirements.

This problem area has not been addressed through a single product offering and solutions are largely based on specific solutions written based on the Microsoft Office suite of products using glues such as Visual Basic and other such languages.

The issues being addressed and solutions offered by Opus include:

* The often-complex reporting requirements of the modern-day industrial business.

* The reliance of users of such data on either IT professionals, either within or external to an organisation that supply services around the generation of reports to user requirements.

* The problem of concentrating different data into a single environment without the associated delays or other layers of software required to access this in realtime.

The Opus solution

Opus solves these problems as it provides solutions to improve the ease of access to data and improve the ease of complex analysis of this data in an easy to use environment.

There are many sources of data in the modern manufacturing entity. From hardware devices such as programmable logic controllers (PLCs), to the human machine interfaces (HMI) systems, databases such as SQL, MS Access. They are all different and supply data in many different ways. Different skills sets are required to access for each area and each have their own idiosyncrasies.

Solutions required

Solutions using standards such as object linking and embedding (OLE), OLE for process control (OPC), OLE for databases (OLEDB) and other such standards and components to create an easy to use set of interfaces into single product environment.

Analysing data has up until now required the skills of mathematicians or highly skilled IT personnel using complex and expensive software products. Ease of analysis of data has been significantly improved by complex mathematical functions being 'hidden' behind an easy to use user interface. A point and click approach to selection of data sources with the results being presented in an easy to understand manner.

The product

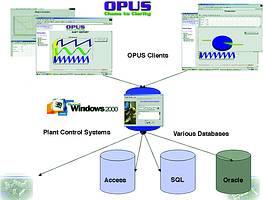

The product consists of two entities, the configuration tool and the client portion.

The configurator

This enables users to configure report templates made up of lines, PI and bar charts in combination with Excel spreadsheets. The data used can be mixed from any number of open sources, databases, OPC servers and various scada products. A user builds his required report by simply selecting the type of display he requires, adds the data from various data sources and then saves this configuration on the report server. Reports are executed on a time - interval or over a particular period of time.

Opus client

In order to execute a report the user simply points his/her browser at the Opus report internet information server (IIS server) and within his browser will appear all the users along with a list of the reports available to be generated. Selecting the report that he wishes to see makes the server aggregate the data from the various sources and then it generates the ASP (active server pages) and pushes this view to the users machine. The Excel component allows the user to export the web-based spreadsheet into the normal Excel environment at the click of a button.

| Tel: | +27 11 658 8100 |

| Email: | [email protected] |

| www: | www.adroitscada.com |

| Articles: | More information and articles about Adroit Technologies |

© Technews Publishing (Pty) Ltd | All Rights Reserved