Coriolis meters are the meters of choice in many liquid measurement applications. But, what about custody transfer applications in the oil industry where every drop counts?

Positive displacement (PD) is a practical and accurate method to achieve volumetric measurement of refined hydrocarbons, according to tests undertaken by Brodie International in the USA. Brodie is a world-class manufacturer of positive displacement technology metering solutions for liquid transfer applications in the energy industry.

The tests revealed that Brodie’s BiRotor Plus (BR+) meter can offer advantages over Coriolis meters for the highest accuracy and reliability. Here are the reasons:

• Moving parts: the measurement tubes of a Coriolis meter continuously vibrate at a high frequency, which can result in material fatigue and reduced life expectancy. The BR+ has two solid moving parts (the rotors) with no material contact, except for its hybrid ceramic bearings and timing gears, resulting in a field-proven life expectancy.

• Pulse generation: the relationship between the vibration of the tubes inside the Coriolis meter and its pulse output is complex with pulses calculated and generated by a microprocessor. This requires complex electronic filtering of the vibration signal and can cause a delay between flow and pulse output. The BR+ generates real pulses that originate directly from the rotor motion.

The pulse output is uniform and works well with all proving methods including Small Volume Provers using pulse interpolation.

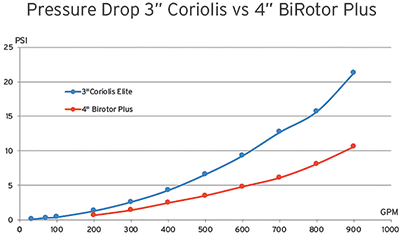

• Pressure drop and changes of pressure: Coriolis meters experience a high pressure drop due to the splitting of the flow into two smaller vibrating tubes. Although it handles the same flow rates, the BR+ is less sensitive to pressure changes.

Meter performance

• Linearity and repeatability: with a published linearity of ±0.075% and a repeatability of 0.02%, the BR+ is a highly accurate custody transfer meter. As with other PD meters, the accuracy of the BR+ improves with increasing viscosity.

Internal product residue

Residue can cause instability in Coriolis tubes, which has implications on the accuracy.

Crude oils which contain paraffin wax often coat the inside tubes of the Coriolis meter. Likewise, viscous oil creates an internal layer on the tubes, the ‘boundary layer’. There are correction procedures in the software to correct this, but these need to be monitored and turned on or off. This adds another level of complication because the operator needs to know when it is needed and when it is not. The BR+ meter is self-cleaning by design and does not require compensation for residue.

Maintenance and proving

• Coriolis meters need to be taken out and sent to the manufacturer for repair. The tubes can suffer from fatigue caused by its high frequency vibration and their replacement is costly. With periodic maintenance, BR+ meters can last for decades and be repaired on site.

• The zero-offset (during low or no flow) of a Coriolis meter needs to be checked and verified periodically. Errors can occur if the tubes become mechanically unbalanced due to coating or erosion. The BR+ does not require Zero setting.

• Complex electronic filtering by a Coriolis meter can cause delays in flow/response measurement. Therefore, a minor change in flow during a proof run can translate to poor repeatability in a Coriolis meter. The pulses of Brodie’s BiRotor+ are created in real-time directly from its pulse wheel, without electronic manipulation. This makes proving straightforward and easy.

Testing and results

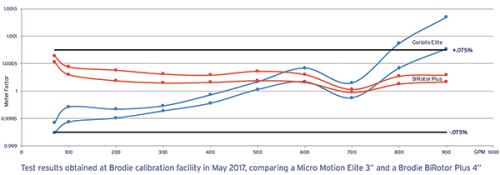

The testing conducted by Brodie consisted of 10 repeatability checks at flowrates from 70 to 900 GPM in 100 gallon increments.

The linearity curve of the 4” BR+ meter was nearly flat. The linearity curve of the 3” Coriolis meter was a steady increase. On the meters tested, the linearity of the BR+ meter was ±0.033% vs ±0.106% for the Coriolis meter.

The 3” Coriolis repeatability spread constantly increased at flowrates greater than 500 GPM. At 900 GPM, the repeatability spread was over four times greater than at 500 GPM.

Based on the results achieved, Brodie calculated the implication on cost due to the uncertainties of both meters.

Assumptions

Application: truck loading rack.

Operating flow rate: 600 gpm (2270 lpm).

Operation: 10 hours/day; 365 days/year.

Annual volume: 131 4000 000 gallons/year.

Gasoline cost per gallon: $0.70.

Uncertainty cost per year:

Coriolis: 1,00042 [max meter factor] – 1,00017 [min meter factor] = 0,00025 [uncertainty].

131 400 000 gallons x 0,00025 [uncertainty] = 32 850 gallons/year.

BiRotor+: 1,00030 [max meter factor] – 1,00016 [min meter factor] = 0,00014 [uncertainty].

131 400 000 gallons x 0.00014 [uncertainty] = 18 396 gallons/year.

Difference between both meters = 14 454 gallons/year i.e. a saving of $10 118/year using the BiRotor+

| Tel: | +27 11 792 2196 |

| Email: | [email protected] |

| www: | www.soliflo.co.za |

| Articles: | More information and articles about Soliflo |

© Technews Publishing (Pty) Ltd | All Rights Reserved