Endress+Hauser makes Process Industry 4.0 accessible through online services and apps that enable users to optimise and maintain their field devices. This way, they can unlock the potential of the field level in just a few steps and reduce plant shutdown.

As a complete provider for process sensory mechanisms, the company has accumulated decades of expertise with a strong range of solutions and services. The new online services enable it to link this expertise with relevant field data. This becomes particularly beneficial thanks to Heartbeat Technology, as it generates additional diagnostic and monitoring information about the sensor and process, for example, sensor wear and tear or deposits in the pipe. To unlock this potential, all that is missing is the data highway from the field devices to online services.

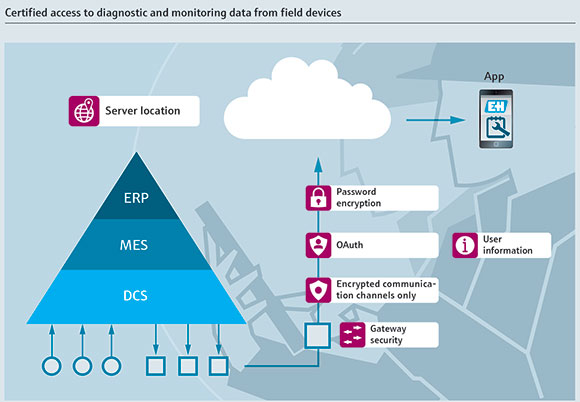

The technical implementation of the data highway is individually tailored customer infrastructure. The focus is on the NOA (NAMUR Open Architecture) concept, so that relevant field data can be supplied, in parallel to the control circuit, through a second communication channel. The data highway is certified by EuroCloud in accordance with the ‘StarAudit’ certificate, so that data is linked and used securely.

Since the digital range has been expanding since 1997, users are able to equip more than 90% of field devices with digital interfaces. With these digital field devices and retro-fit adaptors, there are limitless possibilities for unlocking potential in the field. Early investments in technologies such as the Advanced Physical Layer (APL) will make linking the data to online services even simpler in future.

Paving the way towards Process Industry 4.0

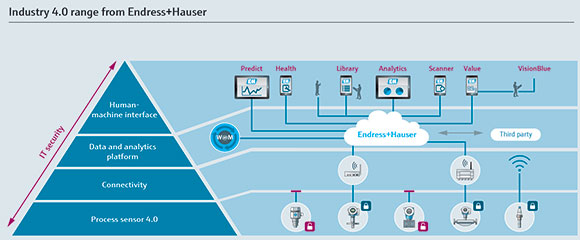

As an independent technology pioneer, Endress+Hauser wants to make the journey towards Process Industry 4.0 together with its customers. To do so, it has given its digitalisation portfolio a modular design. The portfolio consists of sensory mechanisms and connectivity components, as well as applications such as online services and apps, which allows users to choose the specific applications they require to manage and maintain. For instance, they can access online services in any area of the plant using the industrial tablet ‘FieldXpert’, which is suitable for use in hazardous areas. On trial are data glasses such as HoloLens that allow workers to follow instructions while leaving both your hands free. In short, the toolbox for Process Industry 4.0 enables users to make management and maintenance processes simpler and more efficient.

These efforts have already paid off through the German Innovation Award 2018 for Industry 4.0 flagship projects – an impressive Industry 4.0 application for predictive maintenance of measuring points. The implementation of this type of digitalisation project requires skills and expertise spanning different domains, which makes constructive collaboration between industry parties indispensable.

Close collaboration as part of the flagship project also gave rise to a strategically important partnership between SAP and Endress+Hauser, which achieved integration of sensors and algorithms into SAP AIN in order to implement standardised solutions throughout the SAP workflow. After registering the sensor, all relevant information is automatically integrated in the form of a digital twin and kept up to date. Such embedded solutions eliminate the need for many manual and error-prone activities, allowing processes, including the maintenance, to be optimised.

Through these innovative technologies and partnerships, Endress+Hauser is paving the way towards Process Industry 4.0.

For more information contact Natlee Chetty, Endress+Hauser, +27 11 262 8000, [email protected], www.endress.com

| Tel: | +27 11 262 8000 |

| Email: | [email protected] |

| www: | www.endress.com |

| Articles: | More information and articles about Endress+Hauser South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved