Founded in 2015, Pro Project Machinery (PPM) is a bespoke machine building business focusing its skills in the Bag-in-Box (BIB) industry. Bag-in-Box, more commonly known in South Africa as ‘papsak’ (boxed wine), is a growing global industry and PPM makes up a handful of expert machine builders who de-sign these complex machines.

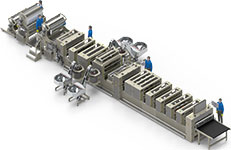

The systems are diverse enough not only to make bags for the wine industry i.e. 3 to 5 litres, but are in fact capable of producing bags with a capacity of up to 250 litres. The machines make either 1, 2 or 4 flexible bags per cycle and are capable of running at 35 cycles per minute. The bags themselves are made up of two or four layers of material, drawn through the machine and processed at different points. Finally, a gland fitment is heat sealed into the bag, after which a tap fitting is inserted into the gland. The product is also heat sealed laterally and horizontally, after which it is cut and then manually packaged into boxes that are delivered to various production facilities to be filled.

PPM as a machine builder is passionate about two elements on any project – using cutting edge technology, and producing equipment that lasts. All machines are drawn up in 3D CAD before manufacturing starts and special care is taken when using specialised parts and other componentry that complements the machine.

In its quest to improve machine performance and get ahead of the competition, PPM partnered with Beckhoff Automation, a leading automation company, to provide the control components for its machines. Beckhoff’s knowledge and experience in the field of motion control have proven an invaluable accompaniment in this regard.

PC-based control and EtherCAT fieldbus support a fast automation architecture

“The first step was undertaking an in-depth analysis of existing machines in the industry and identifying their performance weaknesses,” explains PPM technical director Gareth Schenck. “One of the obvious problems that had to be addressed was the issue of pneumatic cylinders. An average 4-lane machine could use as many as 60 50-bore cylinders, consuming up to 5000 litres of compressed air per minute during operation.

“Replacing these with servo driven electro mechanical cylinders (EMCs) was an inviting alternative. EMCs provided solutions to many existing machine shortcomings in these types of machines, from eliminating the need for large auxiliary compressors, to being able to control the accuracy of sealer bars within micrometres, giving more consistency to the quality of the end product.”

Based on this line of reasoning, the final machine design included a total of 64 servo motors and drives. This posed two problems for the control design team: first, was there an available control system that could simultaneously provide full 64-axis motion control from one unified controller? And second, was there a control network capable of providing the sub 2 ms data transmission times required for accurate machine control?

Beckhoff Automation answered both questions. “Using our PC-based control approach, a CP 6930 industrial PC with multicore Intel® i7 processor easily handled all the motion control requirements. Secondly, the speed of the purpose built EtherCAT network made seamless integration between all 80 of the EtherCAT nodes viable,” explains Dane Potter, a sales engineer from Beckhoff’s Cape Town office.

Overall system improvements

“The tapping insert station, which was transformed from pure pneumatic processes to 4x4-axis motion controlled pick and place using industrial camera imaging to detect defective fitments, as well as orientation, made on-the-fly fitment placing a dream to implement,” outlines Schenck.

“In addition, Beckhoff’s TwinSAFE safety PLC made the often painful integration of safety and control an easy task,” adds Potter. “With 18 light curtain zones, three safety scanners, twenty-two electromagnetic door sensors, and 24 guard sensors, the machine is extremely benign, giving reassurance to operators and maintenance personnel alike that it is safe to work on.”

TwinCAT PLC HMI in conjunction with the 21.5” Beckhoff CP Panel made machine visualisation effortless to implement with its 1080p graphics. This coupled with TwinCAT PLC HMI Web made the ability to view machine metrics on mobile devices uncomplicated and intuitive. Also, PPM utilised the latest AX8000 Servo series, which was not only easy to install and connect due to its modular One Cable Technology (OCT) design, but the built-in FPGA chipset made force feedback extremely accurate.

A large 50” screen at the front of the machine gives personnel a good overview of machine performance, as well as showing warnings to machine operators and packers – a great value add to the machine.

Benefits realised

Using this fast motion control capability, the web speed and sealer bar positions were easily synchronised to achieve maximum machine performance. Also, the decision to use EMCs, which exert far more force than their equivalently sized pneumatic counterparts, resulted in the benefits of faster sealing times, improved machine speed and greater production accuracy. (Machine performance increased from a previous maximum of 7680 bags per hour to a never-before-achieved 8400 bags per hour.)

One of PPMs top customers had this to say about a newly-delivered machine: “The ease of use far exceeds that of any bag maker we’ve had before, and the quietness of the servo actuation also makes for a very pleasant work environment. In monetary terms, we appreciate the fact that running costs have decreased by 60% due to not needing the large amounts of compressed air required previously. We look forward to the improved production capabilities this new design affords us.”

On future machines, PPM will seek to automatically move machine units to facilitate quick and easy setup,” concludes Schenck. “Load cell technology will also be added to bring even greater accuracy to the material sealing aspects.”

For more information contact Michelle Murphy, Beckhoff Automation, +27 11 795 2898, [email protected], www.beckhoff.co.za

| Tel: | +27 11 795 2898 |

| Email: | [email protected] |

| www: | www.beckhoff.com |

| Articles: | More information and articles about Beckhoff Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved