Fire safety at the workplace is a topic that is easily neglected and many businesses do not devote enough attention to it. The topic quickly becomes top of mind when people lose their lives, or when a building or substantial part of an industrial plant is destroyed by fire.

Employees, customers, suppliers and contractors are often not even aware of the fire risks that exist on a specific site, or if they do, they may not be trained for the eventuality. In many instances, businesses want to address their fire risks, but they do not know where to get appropriate guidance on the issue. Fire safety is a wide and specialised field and even if someone at that workplace is tasked to look into the risk, they might not know how to approach the subject, resulting in inadequate policies and measures.

South Africa has strict fire safety legislation in place, but this legislation is often only considered when a new building or plant is being built, or when the insurance companies get involved. Unfortunately, understanding and managing fire risk at the workplace on a continuous basis is the focus of only a very small group of people, even though the lack of understanding of the subject potentially impacts everyone. How can this situation be improved and a culture of fire safety be instilled in the workplace? Dr Niel Jordaan, engineering manager at Sperosens, sheds light on practices that can be helpful to decision makers in this regard.

Best practice from the mining industry

One approach would be to investigate the ‘best practice’ implemented by organisations where fire risk is managed and monitored on a daily basis, like the mining industry.

Mines understand and acknowledge that substantial parts of their operations are inherently risky and pose danger to employees and assets. Mines take fire safety very seriously. It is an integral part of the Mine Health and Safety Act, which governs their operations.

The Department of Mineral Resources also plays an active roll in promoting safety at mines, and published a document in 2016 (DMR 16/3/2/4-B3), called the ‘Guideline for the Compilation of a Mandatory Code of Practice for Prevention of Fires at Mines’.

Quoting directly from this document:

“3.1 The main objective of this guideline is to enable the employer at every mine where a fire could pose a significant risk to the health and safety of persons, to prepare a COP which, if properly maintained and complied with, would improve control measures aimed at preventing fire incidents.”

“3.2 The guideline provides guidance of a general nature on the required format and content of the COP and details sufficient technical background to enable the drafting committee at the mine to prepare a comprehensive and practical COP for the mine.”

The application of the above is compulsory at mines and provides a good general guideline that can be adapted for fire risk management in other industries – even though the Mine Health and Safety Act may not be applicable in those industries – because the general approach is still valid and goes a long way towards addressing fire risks at the workplace.

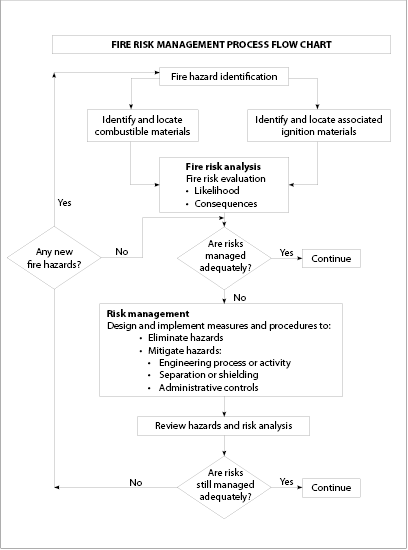

One of the most useful tools from the document is a flowchart that can be used to implement and manage a fire risk process. It is depicted in Figure 1.

This process can be used by fire safety practitioners to address the following:

• Identify the fire hazards at the workplace.

• Evaluate the risk associated with the fire hazard by identifying the likelihood and consequences of the hazard occurring.

• Identify if a hazard is managed appropriately or not.

• If not, identify the steps that can be taken to reduce or eliminate the fire hazard.

Once the hazards are identified, it is much easier to find ways of improving the situation. Often only simple measures are required to improve the situation substantially, for example:

• Keep emergency exits clear.

• Improve housekeeping to reduce flammable materials.

• Improve emergency training of employees.

• Integrate the fire risk assessment with other safety considerations like; water supply for fire suppression, evacuation plans, ventilation, emergency power and the like.

In some instances it will become apparent that the legally required fire equipment was never installed or maintained as per the National Building Regulations. In such instances, it would be prudent to acquire the services of a professional fire services provider, or a life safety assessor, to give expert advice on how to rectify the situation.

In order to improve fire safety at workplace, it is important that the various segments of industry communicate with, learn from and share with each other, the successful tools and practices that have been developed.

Sperosens provides environmental monitoring and fire protection solutions to industry and has done so with an impeccable track record for 30 years.

The company’s products and services are categorised in three separate but linked groups:

• Instrumentation systems designed to remotely monitor safety parameters and equipment performance in underground mining environments.

• Fire protection systems with a focus on the specialised risk category to detect, alarm/warn, contain and extinguish fires in underground and industrial installations.

• IIoT-based measurement and management systems designed to remotely measure and monitor a wide variety of parameters (including safety), as well as equipment performance, in industrial installations and large campus environments.

For more information contact Marihette Hattingh, Sperosens, +27 12 665 0317, [email protected], www.spero.co.za

| Tel: | +27 12 665 0317 |

| Email: | [email protected] |

| www: | www.spero.co.za |

| Articles: | More information and articles about Spero Sensors & Instrumentation |

© Technews Publishing (Pty) Ltd | All Rights Reserved