Dave Wibberley recently attended a conference on IIoT with key partners Mitsubishi Electric and including Copadata and FAG Schaeffler. He felt the outcomes of the conference, global concerns and how to unlock IIoT opportunities, were noteworthy enough to share with both end-users and suppliers.

M2M, IIoT and Industrie 4.0 have been buzzwords in the industry for the last few years, and yet there does not seem to be a significant uptake of large scale projects that deliver on the promises of massive efficiencies and payback using Big Data. New ideas are created by markets to generate and continue to grow businesses, but to generate significant business using IIoT it needs to be approached correctly and be fully understood.

The challenges of approaching IIoT include management, CFOs, CIOs, COOs and CEOs of organisations that are reluctant to change. Wibberley emphasises: “If change is not mandated through legal regulation or there are significant business benefits, humans generally are very reluctant to change or adopt new ideas.”

Various companies presented their own IIoT experiences and after their presentations the groups (made up of suppliers) were split into four streams and asked to list the areas of concerns along with the challenges users are facing in each of the areas. The results were interesting and each point will be discussed using a SWOT (strengths, weaknesses, opportunities and threats) analysis.

Security threat

Security is a problem today. Detection and prevention of cyberattacks are real issues facing companies:

• IT safety including cyber threats and confidentiality.

• Reliability of the last mile connectivity and Internet is important.

• Concerns were raised about the changing face of government regulation and safety standards around using the Internet.

Cloud – opportunity and threat

• Reliability: users are concerned about the reliability of cloud based solutions, large cloud based hosted offerings have built in redundancy to counter this and the cloud is becoming more accepted by users. Industrial corporations are slower and more conservative.

• Accessibility: how accessible and manageable are hosted solutions?

• Costs – there are fears that once corporations are fully committed to hosting and using the cloud, service providers can change prices and thereby make the cost benefits a challenge going forward.

• Predictability: using hosted solutions, offers users IT predictability, it is possible to scale hosted solutions and resources relatively easily and cost-effectively.

• Remote diagnostics: this is a real potential advantage, service providers can use the cloud and Internet to offer diagnostic services remotely and relatively easily to clients on a business or even process level.

• Analytics: Big Data and the advancement of analytics tools being deployed and run by teams of experts makes it very viable to start using expert and artificial intelligence solutions. One of the problems until now has been the bandwidth and availability of experts that use the technologies for customers. With centralised Big Data and remote ‘agents’ this becomes easily and readily accessible, with the potential of large gains in productivity.

Communications – strength and opportunity

• Bandwidth: a lot of work is going into communications and reach by the last mile telecommunications companies. NB-IoT and LORA networks use low power and offer greater bandwidth, albeit using smaller bandwidth is a step forward in the ability to gather bigger and higher resolution data necessary for large benefit IIoT projects.

• Openness and standards: OPC-UA, MQTT and a host of other protocols are allowing interoperability in a secure communications environment, yet offer smaller bandwidth to hardware designers and systems designers.

• Remote services: the spread and availability of Internet communications is allowing the offering of both maintenance and expert remote services. For example, remote process control assistance and tuning, alarm analysis, OEE (overall equipment effectiveness) and other management services around machine performance.

Productivity – strength and opportunity

• Quality: a multitude of increased sensing and measurements being hosted somewhere and analysed by expert systems allows better quality control and assurance.

• Reduced downtime: Big Data and artificial intelligence allows predictability to reach a new level where a cloud based solution predicts failures through software analysis between machines being run all over the world, not even necessarily in a similar business. Backing this with integration into supplier’s databases will see spares inventory being expertly managed based on predictability of failure.

• Flexibility: manufacturing flexibility through a central understanding of capacity and availability will allow manufacturers to make intelligent and optimal decisions around when and where to schedule manufacturing globally based on real-time and future predicted demand trends.

• Total cost of ownership: OEE, condition monitoring and energy management as services could all serve to reduce manufacturing costs.

• Time to market and reduced lead times: can all be supported by IIoT solutions supporting lean manufacturing strategies.

• Global benchmarking: benchmarking is not just an internal process but suppliers can benchmark your performance against global manufacturing companies.

• Mobility: IIoT will see companies changing the way people work. For example mobile technicians could be made available to companies using an ‘Uber’-type application, spawning a new generation of super technicians available and paid for as and when required.

How do you start and activate an IIoT project?

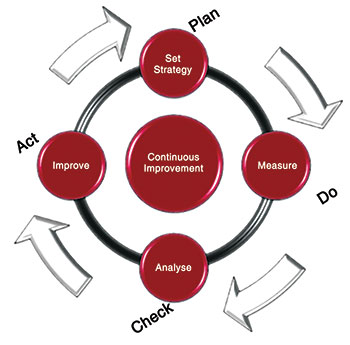

A thorough understanding of your business operations, coupled with how your business is comprised, is needed to take advantage of the points discussed and to really analyse and determine the main drivers for an IIoT project. IIoT should be part of a continuous improvement strategy and programme. Classic PDCA used in Lean Strategy: Plan, Do, Check, Act.

1. What is your goal?

• Costs: energy, productivity and safety.

• Regulation: compliance, quality and traceability.

2. What is influencing or driving your goal?

• Material.

• Energy.

• Labour.

• Service.

• Quality.

• Manufacturing performance.

3. Rank these influences in a value matrix.

• Choose your KPIs.

4. Summarise the ideas to reduce topic costs and identify the best solution and technology.

• May require consulting.

5. Implementation

• Education of management and employees.

• Choice of service providers: internal, external.

• IT infrastructure.

• Education of employees: share knowledge.

6. Measure results constantly.

7. Start at the beginning: benchmark against goals and adjust.

In summary

Wibberley concludes: “IIoT, like all other technology waves, needs to be given careful and studied consideration. It is a significant trend that cannot be ignored as it has the potential to offer good productivity gains.

“IIoT is in its infancy with many competing forces on network, technology, services and applications levels. However, IIoT is here to stay so the choice is when to start using IIoT on new projects and to work on those projects systematically and with purpose.

“Adroit Technologies were the winners of the inaugural MTN – Mind2Machine award and we learned a lot around the deployment and challenges. The main learning areas were data acquisition, sensors and getting this all to a centralised and hosted environment for integration into a large business solution. Without a reliable data acquisition platform and choice of technology the rest will not work, so feel free to pick up the phone and talk to us.”

Dave Wibberley can be contacted on: +27 (0)11 658 8100.

For more information contact Rowena Kemp, Adroit Technologies, +27 (0)11 658 8100, [email protected], www.adroittech.co.za

| Tel: | +27 11 658 8100 |

| Email: | [email protected] |

| www: | www.adroitscada.com |

| Articles: | More information and articles about Adroit Technologies |

© Technews Publishing (Pty) Ltd | All Rights Reserved