As a result of the processes, plants in the oil and gas industry are exposed to a number of dangers. Corrosion is one of them.

Companies generally answer the question of the demands that must be fulfilled by the material of the measuring technology which will be used with the note ‘NACE required’ – meaning, the instruments must be manufactured in accordance with the NACE standard for safety reasons. The question of the specific requirements which are hiding behind this directive is by no means as clear as it seems.

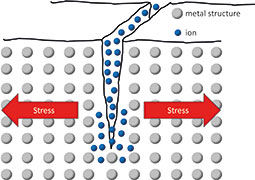

Corrosion is a complex process

For more than 70 years, the renowned National Association of Corrosion Engineers (NACE) has been working on this complex topic. The organisation started considering cathodic corrosion protection in pipelines and is now dealing with every kind of corrosion. The results of this work are published as NACE standards and regularly updated.

Two of these publications, MR0175 and MR0103 (MR = material requirements) refer exclusively to processes in the oil and gas industries. Both standards describe the conditions in the respective environment under which stress corrosion cracking of metals in the presence of hydrogen sulphide (H2S) occurs and with which materials such a development can be countered. Natural gas and oil, as raw products, contain H2S in varying amounts. In the presence of a minimum proportion of this compound and a minimum total pressure, such a mixture is referred to as ‘sour gas’ or ‘sour oil’. The two previously mentioned standards pertain to the pressure and level measuring instruments as well as the thermo-wells which will be used. Temperature measuring instruments do not have to be considered since they can only be installed in the process in combination with a thermowell.

MR0175

Published for the first time in 1975, MR0175 is based on the conditions and experience in the upstream sector, i.e. the extraction of oil and natural gas, and also the exploration of hydrocarbon repositories. It mentions materials for use in H2S-containing environments – commonly referred to as a sour gas atmosphere – where, under elevated temperatures, chlorine-induced stress corrosion cracking (SCC), amongst other effects, can occur.

In 2001, NACE MR0175 was converted to the worldwide ISO 15156 standard and its three parts contain comprehensive guidelines on materials in the oil and gas industry, from the point of view of corrosion technology. ISO 15156-1 provides the basis for the selection of materials which are resistant to crack formation. ISO 15156-2 applies to unalloyed and low-alloy steels and cast iron. ISO 15156-3 applies to high-alloy steels and other alloys. This third section corresponds to NACE MR0175.

For many years, MR0175 has been applied to all sectors of the industry. In 2003, the requirements for the processing of raw materials in refineries (downstream area) were specified separately in an additional standard.

MR0103

MR0103 describes the properties of the materials with regard to hydrogen-induced sulphide stress cracking (SSC), which has its greatest influence at room temperature.

Unless otherwise requested by the user, vendors use MR0175 or ISO 15156-3 as a standard when ‘NACE required’ is commented. Depending on the application, this lists the corresponding requirements and the permitted maximum temperature for the different material groups. Analogous to this ‘framework’, WIKA assigns, for example, its measuring instruments and thermowells to the application categories: ‘Any equipment or component’, ‘Instrumentation and control devices’ and ‘Diaphragms, pressure diaphragms, pressure measuring devices and pressure seals’. The MR0103 standard is constructed similarly in respect to its content.

According to ISO 15156-1 section 5, General principles, the plant operator is responsible for determining which material is appropriate for their application. The measuring instrument manufacturer, on the other hand, is responsible for ensuring the required properties of the material. The corrosion properties of the materials depend on the ambient conditions (pH value, chloride content, H2S concentration, temperature) and the strength of the metals. The ISO/NACE standard contains corresponding limit values for all parameters.

The more information is available about the process in question, the better the measurement solution can be optimised. If the details of the ambient conditions are not sufficiently known, WIKA specifies the operating conditions in accordance with ISO 15156, assuming the most critical situation.

Choice of materials and the NACE requirements

Manufacturers of measuring instruments must ensure that the materials used fulfil the NACE guidelines. This is least expensive when the material with the corresponding mechanical properties is listed in the standard. This procedure is practised, for example, in thermowells for temperature measuring instruments. These are generally manufactured from bar stock and, if necessary, are welded into a process flange. The material properties required in NACE are then certified in the material certificates for the individual parts.

With mechanical pressure measuring instruments, however, this possibility reaches its limits. The measuring element, a Bourdon tube, is usually made of austenitic, cold-hardened stainless steel, on account of its required measurement characteristics. The hardness values of this steel, though, exceed the limit prescribed in the NACE standard. However, qualification can be achieved via a laboratory test – the test conditions are formulated in the standard. In this way, WIKA has been able to validate the applicability of 316L stainless steel pressure gauges for sour gas applications at a temperature of up to 120°C.

Furthermore, measuring instruments can be qualified through operational experience if they have proven their suitability for sour gas applications over a long period without incident. With this alternative, the application temperature must be limited to 60°C, though this is often not sufficient in practice.

Conclusion

The ISO/NACE standard for applications under sour gas conditions in the oil and gas industry is indispensable as the basis for safe processes. For process instrumentation, the room for manoeuvre for suppliers could be increased by providing more detailed information on the individual ambient conditions. An example: for nickel base alloys such as HC276 in a cold-strengthened state, a maximum application temperature of 132°C is valid in the absence of any further detail. If the manufacturer knows that the partial pressure of H2S in the process will be <200 kPa, a maximum value of 232°C would be possible.

For more information contact WIKA Instruments, +27 (0)11 621 0000, [email protected], www.wika.co.za

| Tel: | +27 11 621 0000 |

| Email: | [email protected] |

| www: | www.wika.co.za |

| Articles: | More information and articles about WIKA Instruments |

© Technews Publishing (Pty) Ltd | All Rights Reserved